Hexagon Resources Limited (ASX:HXG)

(“

Hexagon” or the “

Company”) has

completed key testwork directed at enhancing graphite electrodes

used in electric-arc furnaces (“EAF”) worldwide. Graphite

electrodes are an essential part of the EAF steel production

process and comprise a significant portion of cost. The market for

these graphite electrodes is growing and any technology advances

that will extend their service life and lower consumption rates

have significant market appeal.

Hexagon is pleased to report the results of its

successful preliminary downstream technical development work on the

addition of its treated natural graphite as an additive to

synthetic graphite electrodes utilized in the high-growth EAF

market, to manufacture steel. Testing of flake graphite from its

McIntosh Project treated with a proprietary ingredient and branded

as “Performance+”, has demonstrated a positive and

direct correlation between the addition of Performance+ and

increased electrical conductivity and durability in synthetic

graphite electrodes.

EAF steel producers are the dominant consumers of

graphite electrodes, accounting for 90% of all production (GrafTech

International Ltd., 2019). With continued strong demand, prices are

135% higher than they were in Q1 2017 (Roskill, 2019).

Graphite electrodes are consumed every 8 to 10

hours in EAF steel production and are therefore an essential input,

the purchase of which alone accounts for 3 to 5% of steel

manufacturing costs (GrafTech International Ltd., 2019). Testing

indicated that Hexagon was able to successfully extend the service

life of graphite electrodes by reducing electrode lateral

consumption/erosion (oxidative degradation). This was achieved by

pre-treating its purified graphite with the Company’s proprietary

coating, then subsequently mixing the performance-enhancement

additive with synthetic graphite to manufacture graphite

electrodes.

Extending Electrode Service Life and Lower

Energy Consumption.

With Hexagon’s specialized natural-graphite

performance additive for EAF graphite electrodes, the Company was

able to demonstrate reduced energy consumption whilst minimising

electrode consumption in normal EAF operations.

Graphite electrodes have high thermal shock

resistance (structural integrity) and are used to conduct

electricity, while maintaining the ultra-high temperatures (thermal

conductivity) of molten steel during EAF steelmaking. Hexagon’s

technical development work demonstrated a consistent increase in

electrical conductivity and lower coefficient of thermal expansion,

thereby maximising electrical efficiency and reducing energy

consumption.

Hexagon’s Managing Director, Mike Rosenstreich

commented, “the results for Performance+ highlight the potential

for reduced downtime and lower power consumption leading to reduced

costs and smaller carbon footprints in the smelting industry. These

are essential challenges facing the steel industry and leading to a

major transitioning to EAF furnaces in China for example. This

strongly endorses our strategy of seeking high-value, deep-market

opportunities for our natural graphite as set out in our recent

downstream scoping study. Indeed, we are focused on executing that

strategy utilising key elements of the scoping study and the vital

technical know-how gained by studying the natural graphite flake

from the McIntosh Project, doped with a specific ingredient, which

together, offer cost efficiencies in steelmaking.”

KEY POINTS

- Hexagon developed and tested its ultra-high-purity1

natural-graphite concentrate2 treated with a specific antioxidant

additive to optimize performance and reduce the cost of extruded

synthetic graphite electrodes. It has branded this material as

“Performance+”.

- Scanning electron micrographs (“SEM” in Figures 1 and 2)

illustrate the detailed microscopic internal structure of the

enhanced electrodes being proposed by this testwork.

- The company manufactured a total of 38 extruded graphite

electrodes; electrodes manufactured with Performance+ additive

demonstrated consistent enhanced electrode performance — including

true density, bulk density and electrical conductivity performance

— versus the control group (100% synthetic graphite electrodes),

specifically;° 12% increase in true

density° 4.5% increase in bulk

density° 25% increase in electrical

conductivity

- These results highlight the potential of increasing electrical

performance and increasing durability/service lifetime in graphite

electrodes to reduce operating costs. Hexagon’s technical

development work indicates a potential significant new market

opportunity for its transformed graphite material, consistent with

the outcomes of its Downstream Scoping Study released in May

2019.

- EAF technology is regarded as the most efficient and

environmentally sustainable steel manufacturing process in the

world and represents the largest market for graphite

electrodes.

- All downstream technical work was performed by NAmLab3,

Hexagon’s US-based independent laboratory and commercial partner.

Natural graphite used to manufacture Performance+ was sourced from

the Company’s McIntosh Graphite Project in Western Australia.

- Hexagon is in discussions with multiple US-based graphite

electrode consumers and manufacturers.

Figure

1: https://www.globenewswire.com/NewsRoom/AttachmentNg/9f3a0de1-a458-475b-8ca8-58d1c92827ae

______________________1 Thermally purified to ≥

99.95% Carbon total percentage by weight (wt% C).2

Graphite flake size fraction of -60/+100 mesh.3 NAmLab refers to

Hexagon’s US-based, downstream technical and commercial partner

whose identity cannot be disclosed due to confidentiality

obligations.

1.

COMMENTARY

Electric-arc furnaces (“EAFs”) are used to

manufacture steel and are regarded as the most efficient and

environmentally sustainable production technology currently

available. Due to unique physical properties, graphite electrodes

are a critical, non-substitutable industrial consumable in

EAF-based steel production.

With an average selling price of approximately

US$10,000 per tonne, worldwide graphite electrode production

capacity was approximately 800,000 tonnes in 2018, forecast to

reach 850,000 tonnes in 2019 (GrafTech International Ltd., 2019).

Roskill (2019) reports that electrode production consumed

approximately 750,000 tonnes of synthetic graphite in 2018,

consistent with Graftech’s production estimates and underpinning

the deep nature of this market opportunity

Made from a petroleum coke precursor, synthetic

graphite is engineered to exacting specifications with high purity

and predictable electrical, thermal and mechanical properties, but

is less conductive and significantly more expensive than natural

graphite. Unlike synthetic graphite, natural flake graphite cannot

be sintered (meaning, formed into blocks) and can therefore only be

utilized as an additive for electrode applications.

However, given the significant size and strong,

enduring demand profile of the graphite electrode industry and in

keeping with Hexagon’s stated focus on producing downstream highly

specialized industrial and energy graphite products, the Company

sought to develop a natural-graphite additive to enhance the

electrical performance of the synthetic graphite electrodes. In

addition to increasing electrical performance, Hexagon sought to

extend the service life of graphite electrodes by partially

inhibiting electrode decomposition through building an

oxidation-resistant layer. Oxidation is the primary limitation to

the operational life of graphite electrodes.

2.

‘PERFORMANCE+’ — DEVELOPMENT OBJECTIVES

High-quality graphite electrodes have low

electrical resistivity and strong durability. Hexagon believed it

could improve both these performance characteristics by hybridising

a natural-graphite additive in synthetic graphite electrodes.

Purified natural flake graphite exhibits a much

higher crystalline structure than synthetic and is therefore more

electrically and thermally conductive. The fewer the elemental

impurities in the graphite, the better its electrical conductivity.

With this understanding, Hexagon sought to achieve maximum

electrical conductivity utilising ultra-high-purity natural flake

graphite, as opposed to non-purified materials.

Graphite electrode consumption during smelting is a

significant component of the cost of steel production in EAF

operations. Increased electrical conductivity holds the potential

to reduce consumption losses in electrodes by utilising higher

voltages and lower currents (long-arc operation). To further

enhance electrode service, Hexagon developed a low-consumption-rate

antioxidant pre-treatment coating in order to reduce electrode

consumption losses due to lateral oxidation. Oxidative degradation

involves the disintegration of macromolecules by the action of

oxygen on the graphite substrate of the electrode.

Oxidation causes graphite to be consumed or burned

off during use in the smelting process. When heated in air at

elevated temperatures (e.g. when graphite electrodes are dipped

into an EAF’s molten metal) graphite burns (or gets oxidized),

leading to the formation of volatile carbon dioxide. This parasitic

loss of carbon as volatile gases is the primary limitation to the

operational life of graphite electrodes. By lowering the linear

coefficient of thermal expansion (“CTE”), Hexagon’s antioxidant

pre-treatment coating of the natural flake, improves electrode

structural integrity by increasing density (reducing porosity). A

low CTE minimizes electrode consumption by maximizing efficient use

of electricity in the EAF while maintaining its structural

integrity.

Figure

2: https://www.globenewswire.com/NewsRoom/AttachmentNg/d71ac590-51f9-4ceb-b1c3-b92bb4691b49

3.

BACKGROUND — INDUSTRIAL APPLICATION

To provide context to the significance of the

results described above and detailed further below it is useful to

provide a brief overview of the industrial electrode manufacturing

process and EAF utilisation in steel making — whilst acknowledging

other EAF furnace applications may also be relevant.

Manufacturing of graphite electrodes is a highly

technical industrial process with very demanding technical

specifications that require compliance to ensure efficient EAF

operations.

In size, the electrodes maybe up to ~81 cm (32

inches) in diameter, more than ~3.4 m (11 feet) in length and can

weigh more than 2.6 tonnes. The manufacturing timeline is between 3

to 6 months.

Operationally, electrode consumption varies between

2 to 3 kg per tonne of steel and 8 to 10 hours of production.

3.1 Graphite Electrode

Manufacturing

The graphite electrode manufacturing process

includes the following main processes set out below with reference

to the testwork samples:

- Screening and mixing of raw materials (green or raw petroleum

coke) and blending with coal tar pitch to form a dense

paste.Hexagon’s Performance+ additive material was added to

synthetic graphite.

- Formation or extrusion of the electrode.The paste was passed

through a proprietary extruder mixer to form elongated rods of

uniform diameter.

- Calcining or Baking of the electrode to decompose and

devolatilize (purify) the petroleum needle coke by removing organic

materials, moisture and volatile combustible matter, thereby

increasing the fixed carbon content, electrical conductivity and

real/true density in the resultant calcined petroleum coke

(“CPC”).Hexagon’s extruded graphite rods were calcined at 900 ̊C in

an inert (nitrogen gas) atmosphere for 15 hours.

- First Pitch Impregnation (“1PI”) which consists of

impregnating/soaking the electrode with tar pitch binder to reduce

porosity or void fractions within the graphite rod to improve

strength.Following calcination, the graphite rods were soaked in a

solution of tar pitch for 1 hour.

- Re-Calcining or Re-Baking — this step is to ensure that all

voids within the rods are filled with pitch coke binder.

- Second Pitch Impregnation (“2PI”) — to ensure that all gaps

within the rods are filled with pitch coke binder.

- Graphitization — removes additional impurities and improves the

electrodes’ key qualities: thermal and electrical conductivity,

thermal shock resistance performance, lubricity, and abrasion

resistance.

- Machining to create the exact sizes and smooth surface.

3.2 EAF Steel Industry

EAF steelmaking grew at an annual pace of

approximately 14% in 2017, compared with 4% for steelmaking

overall. As a result of the increasing global availability of steel

scrap and the more resilient, high variable cost and

environmentally friendly EAF model. Electric vehicle (“EV”) battery

demand for petroleum needle coke has constrained supply and pushed

market prices higher.

Roskill reports (2018) that EAF steel production

accounts for approximately 27% of global production, but only 7% of

Chinese steel production. There is a positive growth outlook

particularly in China where government initiatives are forcing a

transition to EAF smelting from the historical dominance of basic

oxygen furnace (“BOF”) steel producers. These initiatives are the

result of efforts to eliminate excess steelmaking production

capacity and to improve environmental conditions. The EAF method

produces approximately 25% of the carbon dioxide (or CO2) emissions

of a BOF facility and does not require the smelting of virgin iron

ore or the burning of coal. Additionally, as a result of

significantly increased steel production in China since 2000, the

supply of Chinese scrap is expected to increase substantially,

which may result in lower scrap prices and provide the Chinese

steel manufacturing industry with local scrap feedstock that was

not historically available. Hexagon believes these trends will

allow EAF steel producers to increase their market share and grow

at a faster rate than BOF steel producers, resulting in increasing

demand for graphite electrodes, which in turn, will create a

potentially significant demand and commercial adoption for EAF

electrode enhancement additives that reduce costs and increase

performance in EAF electrodes.

4. TEST

RESULTS

Performance+ testing in graphite electrodes

indicated a direct relationship between the amount of natural

graphite added to the electrode matrix and increased performance of

several electrode properties, including (refer Tables 1-3):

- increased electrical conductivity

- higher bulk density

- improved mechanical properties

- a potential for extended electrode service life

As weight percent addition of natural graphite to

synthetic increased, the density of electrodes increased reaching

an impressive 1.62 g/cm3 at 2.5 wt.% flake addition to the

electrode mix.

Further, testing consistently outperformed the

all-synthetic control in density and conductivity.

The following section discusses three key testwork

parameters; Bulk Density, True Density and Electrical

Conductivity.

4.1 Bulk

Density Bulk Density is also called apparent density or

volumetric density. It is a characteristic of a volume of divided

material such as powders, grains, and granules.

The best result was a 4.5% improvement from 1.55

g/cm3 to 1.62 g/cm3 for the 2.5% Performance+ addition.

Density can be both an indicator and result of the

particle size, strength and porosity inherent in a specific

graphite material, because the larger the particle size and more

openings filled with air, the lower the density.

The density of graphite can be adjusted by the raw

materials, formulation and manufacturing processes used to create

the specific material grade during initial production. The finished

graphite material's density may also be increased though the use of

additives and impregnations that will fill in the open porosity of

the base graphite material.

Porosity is an undesirable phenomenon in electrodes

as porosity leads to reduced electrode density, and typically,

lower mechanical strength and electrical conductivity.

When graphite flakes have been compressed under a

high pressure, each of them will come closer and, consequently, the

density of bulk graphite becomes higher. Higher density of bulk

graphite leads to higher electrical conductivity because there is

greater connectivity for the electrons to move across the graphite

particle. In contrast, a lower density of the bulk graphite

indicates a high level of voids which strongly reduces electron

mobility, thus, resulting in a lower electrical conductivity of the

bulk graphite.

Bulk density is typically how this value is

reported on most graphite material specification sheets.

Table 1: Bulk Density

Determinations.

|

Graphite Electrode |

Addition of Natural Graphite (%) |

Addition of

SyntheticGraphite(%) |

Weight before

Graphitization(g) |

Weight after

Graphitization(g) |

Weight Lost during Graphitization (%) |

Specimen Height(cm) |

Specimen Volume(cm3) |

Electrode Bulk

Density(g/cm3) |

|

Hexagon Performance+

additive |

2.5 |

97.5 |

82.9 |

82.3 |

0.72% |

10.03 |

50.80 |

1.62 |

|

Hexagon Performance+

additive |

5 |

95 |

64.7 |

63.7 |

1.55% |

8.44 |

42.75 |

1.49 |

|

Hexagon Performance+

additive |

7.5 |

92.5 |

58.1 |

56.6 |

2.58% |

6.98 |

35.38 |

1.60 |

|

Hexagon Performance+

additive |

10 |

90 |

73.5 |

68.6 |

6.67% |

8.68 |

43.97 |

1.56 |

|

Control (100% Synthetic Graphite) |

0 |

100 |

51.1 |

48.5 |

5.09% |

6.18 |

31.29 |

1.55 |

|

|

|

|

|

|

|

|

|

|

4.2 True

Density Data

True density is determined by taking the mass of a

particle and dividing by its volume, excluding open and closed

pores. A constant value for a matter, true density is the

density of the near net shape.

True density in this case is a measure of how

graphitic a material is. The best result was a 12% increase from

1.95 g/cm3 in the control sample to 2.18 g/cm3 with a 5%

Performance+ addition.

The high true densities suggest that the electrodes

are made of highly graphitized material that should be as

conductive as possible to furnish the best level of current

carrying capability. By testing true density, the graphitization

degree variable was effectively eliminated.

The highest density recorded was the 10% addition

of Performance+, although 5% is ideal when the mechanical strengths

component is added to the overall equation.

Table 2: True Density

Determinations

|

Graphite Electrode |

Addition of Natural Graphite (%) |

Synthetic GraphiteContent

(%) |

Electrode True Density (g/cm3) |

|

Hexagon Performance+

additive |

2.5 |

97.5 |

1.83 |

|

Hexagon Performance+

additive |

5 |

95 |

2.18 |

|

Hexagon Performance+

additive |

7.5 |

92.25 |

no data |

|

Hexagon Performance+

additive |

10 |

90 |

2.24 |

|

Control (100% Synthetic Graphite) |

0 |

100 |

1.95 |

|

All electrodes were double pitch-impregnated (2PI). |

|

|

4.3 Electrical Resistivity

Data

Electrical resistivity (also referred to as

resistivity, specific electrical resistance, or impedance), is an

intrinsic property that quantifies how strongly a given material

resists the flow of electric current. A low resistivity indicates a

material that readily allows the flow of electric current.

Electrical conductivity or specific conductance is the reciprocal

of electrical resistivity and measures a material's ability to

conduct an electric current.

The best result was a 25% enhanced conductivity

with resistivity (the inverse of conductivity) declining from 11.88

μΩ·m in the control sample to 9.01 μΩ·m in the electrode, with a 5%

addition of Performance+.

Electrical conductivity of bulk graphite is

regarded as a function of its volume density and temperature. In

general, increasing the compression pressure mechanically reduces

the gaps between carbon particles, directly enhancing the

electrical contact. The electrical conductivity of graphite depends

on the separation distance between each particle and the average

particle size.

The higher the concentration of Hexagon’s natural

flake graphite in the composition of extruded shapes, the lower the

resistivity. This demonstrates that Hexagon’s Performance+ additive

has a positive effect on the conductivity enhancement phenomenon in

graphite electrodes. At 5% and higher, test series became better

than the synthetic control with greater percent addition of flake

additive to the electrode formulation. Refined flake reached the

resistivity level of the 3PI control formulation at 5 wt. %

addition of flake to synthetic.

Table 3: Resistivity

Determinations

|

Wt.% addition into synthetic graphite |

Hexagon natural Performance+

additive (2

PI) |

Synthetic Control (2

PI) |

Synthetic Control (3

PI) |

|

0 |

n/a |

11.88 μΩ·m |

9.24 μΩ·m |

|

2.5 |

13.60 μΩ·m |

|

|

5.0 |

9.01

μΩ·m |

|

7.5 |

8.85 μΩ·m |

|

10 |

8.65 μΩ·m |

|

|

|

|

|

5. TEST

METHODS

5.1 Electrode Manufacturing

Graphite electrodes were produced by first mixing

petroleum tar pitch suspended in a compatible solvent system,

varying amounts of synthetic graphite, Hexagon unpurified or

thermally purified graphite, and the doping additive to form a

thick paste. The resulting paste was passed through NAmLab’s

proprietary extruder mixer to form elongated rods of uniform

diameter as shown in Figure 3.

These rods were calcined (i.e. baked) at 900° C in

an inert nitrogen atmosphere for 15 hours. Following calcination,

the graphite rods were soaked in a solution of tar pitch for 1 hour

to allow the pitch to fill any voids, allowed to air dry and then

calcined again to convert the tar pitch into pitch coke. Depending

on the specific samples, the soaking and calcination steps were

repeated one to two more times (i.e. 2PI or 3PI) to ensure that all

gaps within the rods are filled with pitch coke binder. Heat

treatment makes electrodes harder, but after 2nd PI and especially

3rd PI they also gain strength.

After completion of the final calcination step, the

dry weight of the un-graphitized electrodes was measured prior to

being graphitized at 2,800° C. Once retrieved from the furnace, the

mass of the electrodes was measured to assess the electrode weight

loss during the graphitization process.

The resistivity of the resulting graphitized

electrodes was tested in accordance with ASTM C611, which required

the machining of electrodes using a lathe and precision cutting

tools, to a length diameter ratio of between 6:1 and 4:1.

The true density of 23 electrodes was measured

using the Quantachrome Helium Multipycnometer. Since this test

required powdered material, testing the true density of the entire

electrode was not possible. Instead, the leftover shavings produced

during machining of the uneven electrode ends were set aside and

crushed; the resulting powder was then used for true density

testing. True density is a measure of how graphitic a material is;

the theoretical true density of pure crystalline graphite is 2.254

g/cm3, while a material with a true density of 1.9 g/cm3 is

synthetic and moderately graphitized. It has been argued that the

theoretical true density of graphite cannot be measured via helium

pycnometry due to the particles’ porosity but crushing the

electrodes and pressing the powder allowed for a more accurate true

density reading.

Figure

3: https://www.globenewswire.com/NewsRoom/AttachmentNg/55572589-6a0a-4eb5-9b84-e10baf2c98fd

5.2 Bulk Density

Determinations

The bulk density of electrodes has been determined

by dividing the weight of the electrode after graphitization by its

volume. Utilising NAmLab’s in-house extruder, the measured values

were close to the bulk densities of industrially made electrodes,

although some density values were slightly lower. The lowest bulk

density recorded in the study was 1.31 g/cm3 with the highest value

at 1.63 g/cm3 (refer to relevant results in Table 1). For

reference, industrially made electrodes range in bulk density from

1.58 to 1.65 g/cm3.

All electrodes produced in this study had a fixed

diameter of 2.54 cm and varying length, which is indicated by the

varying weight data in Table 1. Electrodes after a single pitch

impregnation (denoted as 1PI) and a single calcination, lost up to

18-23% of mass upon graphitization. Those electrodes had the lowest

density in a given test series, clearly revealing significant

amounts of open porosity and are not reported further herein, as

they are not relevant to the industry sector.

The electrodes denoted as 2PI had the lowest mass

reduction of volatile matter during graphitization (typically, 0.5

to 5 wt.%). Their resultant bulk density values where notably

higher, possibly as a consequence of effective filling of pores in

the extruded shapes by pitch.

Importantly, as mass additions of Performance+

natural flake graphite additive to the synthetic graphite

increased, the bulk density of graphitized electrodes

increased.

5.3 True Density

Determinations

As part of this study. NAmLab sought to determine

the density (specific gravity) of graphite materials using an

analytical method of gas (helium) expansion pycnometry. This is a

widely recognized technique for precision determination of volume

of crystalline matter — such as graphite electrodes.

Helium pycnometer operates on a principle of gas

displacement and the volume-pressure relationship (Boyle's Law).

Helium pycnometry is expected to deliver the value of 2.266 g/cm3

at 293K for a 100%-pure monocrystalline graphite. A Quantachrome

Instruments’ He/N2 gas Multipycnometer was used in this study.

The samples comprised powders made from the crushed

machine shavings of the 23 electrodes tested. A minimum of two true

density measurements were taken for each electrode as a minimum,

and the densities were averaged to determine the final true density

values as presented in Table 3.

5.4 Electrical Resistivity

The resistivity of graphitized electrodes has been

assessed in accordance with ASTM method C 611-98, entitled:

“Electrical Resistivity of Manufactured Carbon and Graphite

Articles at Room Temperature”.

According to the aforementioned test method, a low

electric current is run through the graphite electrode to prevent

sample heating while the voltage across a specified length of the

surface of the graphite electrode is measured to enable calculation

of the resistivity. To account for anisotropy in the cylindrical

graphite electrode, this measurement is repeated following

sequential 90-degree rotations of the electrode and/or by testing

of a machined shape in the form of a bar. If testing a cylinder,

these four measurements are then repeated using a reversed current

flow and switched voltmeter electrode configuration to account for

any material memory effects and voltage measurement biases. The

result is 16 separate resistivity measurements that, when averaged,

provide a representative measure of the graphite electrode’s

resistivity.

A 4-point resistivity test was conducted on the

electrodes and the results presented in Table 3.

Exploration Results and Mineral Resource

Estimates The information within this report that relates

to exploration results, Exploration Target estimates, geological

data and Mineral Resources at the McIntosh and Halls Creek Projects

is based on information compiled by Mr. Mike Rosenstreich who is an

employee of the Company. Mr. Rosenstreich is a Fellow of The

Australasian Institute of Mining and Metallurgy and has sufficient

experience relevant to the styles of mineralisation and types of

deposits under consideration and to the activities currently being

undertaken to qualify as a Competent Person(s) as defined in the

2012 edition of the Australasian Code for Reporting of Exploration

Results, Mineral Resources and Ore Reserves and he consents to the

inclusion of this information in the form and context in which it

appears in this report.

Metallurgical Test Work Outcomes

The information within this report that relates to metallurgical

test work outcomes and processing of the McIntosh material is based

on information provided by a series of independent laboratories.

Mr. Rosenstreich (referred to above) managed and compiled the test

work outcomes reported in this announcement. A highly qualified and

experienced researcher at NAmLab planned, supervised and

interpreted the results of the NAmLab test work. Mr. Michael Chan

was a full-time employee of Hexagon Resources Limited at the time

these results were reported, and he also reviewed the metallurgical

test work outcomes. Mr. Chan is a Metallurgical Engineer and a

Member of the Australasian Institute of Mining and Metallurgy. Mr.

Chan and the NAmLab principals have sufficient relevant experience

relevant to the style of mineralisation and types of test-work

under consideration and to the activities currently being

undertaken to qualify as a Competent Person(s) as defined in the

2012 edition of the Australasian Code for Reporting of Exploration

Results, Mineral Resources and Ore Reserves and had consented to

the inclusion of this information in the form and context in which

it appears in this report.

About Hexagon Resources

LimitedHexagon Resources Limited is listed on the

Australian Securities Exchange (“ASX”) under the ticker code “HXG”.

The Company holds a 100% interest in the McIntosh Graphite Project

in Western Australia and an 80% interest in the Ceylon Graphite

Project in Alabama, USA. With a current focus on the downstream

processing of graphite and other energy materials, Hexagon has

attained formidable technical knowledge based on test work of its

McIntosh project flake-graphite material, which is applicable and

highly valuable for a range of specialty-material applications. The

Company’s focus is on creating sustained shareholder value by

maximizing near-term growth opportunities to commercialize that

downstream business in the USA, where it has forged strong

technical, commercial and investor relationships.

Learn more at www.hexagonresources.com

Forward-Looking StatementsThis

news release contains projections and statements that may

constitute "forward-looking statements" within the meaning of

applicable United States, Canadian and other laws. Forward-looking

statements in this release may include, among others, statements

regarding the future plans, costs, objectives, or performance of

Hexagon Resources Limited or the assumptions underlying any of the

foregoing. In this news release, words such as "may", "could",

"would", "will", "likely", "believe", "expect", "anticipate",

"intend", "plan", “goal”, "estimate," and similar words, and the

negative forms thereof, are used to identify forward-looking

statements. Forward-looking statements are subject to known and

unknown risks, uncertainties and other factors that are beyond the

control of Hexagon Resources Limited, and which may cause the

actual results, level of activity, performance or achievements of

Hexagon Resources Limited to be materially different from those

expressed or implied by such forward-looking statements. Such risks

and uncertainties could cause actual results, plans and objectives

of Hexagon Resources Limited to differ materially from those

expressed in the forward-looking information. Hexagon Resources

Limited can offer no assurance that its plans will be completed.

These and all subsequent written and oral forward-looking

information are based on estimates and opinions of Hexagon

Resources Limited management on the dates they are made and

expressly qualified in their entirety by this notice. Except as

required by law, Hexagon Resources Limited assumes no obligation to

update forward-looking information should circumstances or the

estimates or opinions of Hexagon Resources Limited management

change.

Contact

Hexagon Resources Limited Mike Rosenstreich CEO

and Managing Director

North American Media and Investor Relations

Contact:G&W Communications Inc.

telephone: +1 416 265 4886email: hexagon@g-w.ca

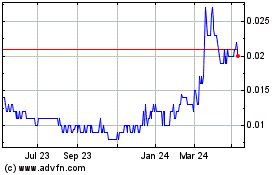

Hexagon Energy Materials (ASX:HXG)

Historical Stock Chart

From Nov 2024 to Dec 2024

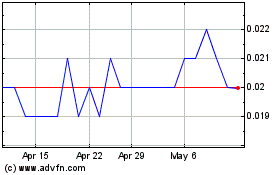

Hexagon Energy Materials (ASX:HXG)

Historical Stock Chart

From Dec 2023 to Dec 2024