BacTech Releases Positive Flotation Results for Telamayu Tailings

29 April 2014 - 2:05AM

Marketwired Canada

BacTech Environmental Corporation ("BacTech") (CSE:BAC)(OTC:BCCEF) (WKN: A1H4TY)

announced today the initial flotation results for the Telamayu tailings project

located in Potosi state, Bolivia.

BacTech enlisted the services of SGS Bolivia S.A. to oversee the sampling of

some 2,000 bags of tailings assembled by COMIBOL, the Bolivian state mining

company. In essence material was bagged at 1 meter intervals by COMIBOL from 8

test holes of roughly 10 meters in depth. A "pipe" was used to extract a sample

from every bag and a larger sample of 200 kg was created. This larger sample was

bagged and secured at site before making its way to Lima, Peru. From there, the

samples were shipped to Inspectorate Exploration and Mining Services Ltd. in

Vancouver, Canada. The Company has not investigated or verified the sampling

program conducted by COMIBOL.

Assay chart

----------------------------------------------------------------------------

Element Unit Telamayu Tailing Comp.

----------------------------------------------------------------------------

Ag g/mt 275.0

----------------------------------------------------------------------------

Au g/mt .24

----------------------------------------------------------------------------

As ppm 3145

----------------------------------------------------------------------------

Sb ppm 953.61

----------------------------------------------------------------------------

Cu ppm 22417

----------------------------------------------------------------------------

Bi ppm 557.97

----------------------------------------------------------------------------

Sn ppm 1571.8

----------------------------------------------------------------------------

Flotation results

----------------------------------------------------------------------------

Max.metal recovered

Element to concentrate Recovery

----------------------------------------------------------------------------

Ag 35 oz/t 60-64%

----------------------------------------------------------------------------

(i)Cu 4.2-4.4% 33-35%

----------------------------------------------------------------------------

As 0.65% n/a

----------------------------------------------------------------------------

(i)Copper recovery is 33-35% of the remaining unoxidized sulphides in the tailings.

It was noted that roughly 50% of the sulphides in the sample had been oxidized.

Two rougher kinetic flotation tests were carried out on the sample at different

grinds to evaluate the tailings response to flotation. Results from these

preliminary tests showed that after four stages of rougher flotation

approximately 15% of the material was removed to a bulk rougher concentrate

assaying 31-35oz/t silver (60-64% recovery), 4.2-4.4% (33-35% recovery) copper

and 0.65% arsenic. Additional tests will be undertaken to attempt to improve the

recoveries for the silver component.

In addition to silver and copper the assays showed significant values reported

for tin, antimony and bismuth. Gravity work will also be undertaken to

compliment this preliminary flotation work. The objective will be to evaluate

possible benefits of applying both techniques for upgrading metals of value into

concentrates for further treatment. For example the tin grade of the sample was

assayed at 0.157% equating to 3,900 tonnes of contained tin (current price

$23,500/t).

The copper recovery into concentrate at first glance would appear to be

disappointing but upon further investigation it appears that approximately one

half of the copper was extracted before flotation into the grind/wash water. If

this is the case then recoveries of up to 80% were achieved if the wash water is

included in the calculation. That is to say an operation may include a washing

process from which the soluble copper is recovered prior to flotation.

BacTech will continue to investigate different approaches combining gravity for

free silver and tin with flotation for silver and copper.

About Telamayu

COMIBOL advised that the tailings at Telamayu were generated by a centralized

milling operation that treated material from 2 local mines, namely Animas and

Seven Suyos. The site contains some infrastructure including an operating rail

line, a power substation, a reliable water source and a plant housing that could

possibly be used to house a flotation circuit. COMIBOL has estimated that there

are approximately 2.3M tonnes of tailings attributable to the above assay

results, and across the river is an additional 3M tonnes of tailings from the

same source, but no work has been initiated there at this time. In addition,

there are 2 additional tailings sites within 50 km that could be investigated in

future.

The tonnages provided by COMIBOL are of a historical nature and have not been

confirmed by the Company. BacTech is not treating the historical estimate as

current mineral resources or mineral reserves as they are not NI 43-101

compliant. The Qualified Person ("QP") on the press release is Gary Williams,

P.Geo.

BacTech Profile

BacTech Environmental Corporation holds the perpetual, exclusive, royalty-free

rights to use the patented BACOX bioleaching technology for the reclamation of

tailings and mining waste materials. In November 2011, BacTech signed a contract

with the Mines Branch of the Manitoba Department of Innovation, Energy and

Mines, to remediate an arsenopyrite gold stockpile situated at the Snow Lake

Mine in Snow Lake, Manitoba. The Company continues to field enquiries globally

with respect to additional opportunities for remediation.

Follow us on:

Facebook http://www.facebook.com/BacTechGreen

Twitter http://twitter.com/BacTechGreen

LinkedIn http://www.linkedin.com/company/1613873

Vimeo http://vimeo.com/bactechgreen

Youtube http://www.youtube.com/user/bactechgreen

Special Note Regarding Forward-Looking Statements

This news release contains "forward-looking information", which may include, but

is not limited to, statements with respect to future tailings sites, sampling or

other investigations of tailing sites, the Company's ability to make use of

infrastructure around tailings sites or operating performance of the Company and

its projects. Often, but not always, forward-looking statements can be

identified by the use of words such as "plans", "expects", "is expected",

"budget", "scheduled", "estimates", "forecasts", "intends", "anticipates", or

believes" or variations (including negative variations) of such words and

phrases, or state that certain actions, events or results "may", "could",

"would", "might" or "will" be taken, occur or be achieved. Forward-looking

statements involve known and unknown risks, uncertainties and other factors

which may cause the actual results, performance or achievements of the Company

to be materially different from any future results, performance or achievements

expressed or implied by the forward-looking statements. Forward-looking

statements contained herein are made as of the date of this news release and the

Company disclaims, other than as required by law, any obligation to update any

forward-looking statements whether as a result of new information, results,

future events, circumstances, or if management's estimates or opinions should

change, or otherwise. There can be no assurance that forward-looking statements

will prove to be accurate, as actual results and future events could differ

materially from those anticipated in such statements. Accordingly, the reader is

cautioned not to place undue reliance on forward-looking statements.

Shares outstanding 48,755,027

The Canadian National Stock Exchange (CNSX) has not reviewed and does not accept

responsibility for the adequacy or the accuracy of the contents of this release.

FOR FURTHER INFORMATION PLEASE CONTACT:

Ross Orr, President & CEO

BacTech Environmental Corporation

416-813-0303 ext 222

info@bactechgreen.com

Bill Mitoulas, Investor Relations

BacTech Environmental Corporation

416-479-9547

bmitoulas@bactechgreen.com

www.bactechgreen.com

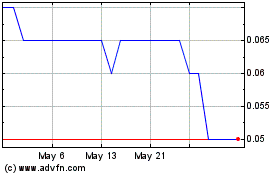

BacTech Environmental (CSE:BAC)

Historical Stock Chart

From May 2024 to Jun 2024

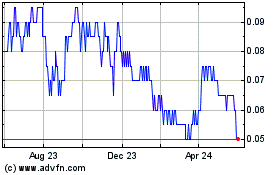

BacTech Environmental (CSE:BAC)

Historical Stock Chart

From Jun 2023 to Jun 2024