Monument Mining Limited (TSX-V: MMY and FSE: D7Q1) ("Monument" or

the "Company") is pleased to announce that the independent

flotation testwork undertaken at Bureau Veritas Laboratory (“BV”)

in Perth has successfully replicated the positive results achieved

by the on-site metallurgical laboratory to produce a marketable

gold concentrate at the Selinsing Gold Mine.

CEO and President Cathy Zhai commented: “We are

very pleased with the test results that are a milestone step in

achieving a sustainable cash supply from our Selinsing gold

sulphide inventory by the sale of a sulphide concentrate produced

through the planned flotation plant to third parties. The Phase II

plant upgrade may follow to construct a BIOX-leaching circuit if

deemed economically viable to treat both the Selinsing concentrates

and third party concentrates on-site in order to further enhance

the revenue level. Our new business model of expanding

operations into treating third parties concentrates through a

planned BIOX®-leaching circuit continues to be assessed.”

She further added: “We have noted that the

recent announcements of tighter Chinese import restriction for the

arsenic levels in gold concentrates imply that a number of

producers of complex gold concentrates that currently sell into

China will be looking for new off-take partners. Consequentially

Selinsing’s proposed BIOX® plant could be their new home.”

Flotation Testwork Results

Highlights

- Gold concentrate produced from fresh sulphide ore contains an

average 34g/t of gold from BV testwork, compared to 33.1g/t of gold

from the on-site Selinsing testwork;

- Gold concentrate produced from transition sulphide ore contains

an average 42.5g/t of gold from BV testwork compared to 31.7g/t of

gold from the on-site Selinsing testwork;

- The arsenic (“As)” contained in gold concentrates was achieved

at an average of 5.1% for fresh and 7.0% for transition ores close

to the 8% limit that initially set for the testwork program.

It can be lowered to 3.5% through concentrate blending.

- Final concentrate grades showed elevated antimony (“Sb”) grades

in the fresh material (5.7 – 13.3% Sb), but less than 0.2% Sb in

the transition ores.

Orway Mineral Consultants (“OMC”) was engaged by

the Company to modify the flotation conceptual engineering design

that was reported in the Snowden feasibility study in February

2019, in order to produce gold concentrates as a final product for

sale instead of a mid-product for further bio-leach treatment to

accommodate a two stage approach Sulphide treatment plant expansion

strategy.

The independent testwork was carried out from

February to May 2021 in Perth, Australia through Bureau Veritas

Laboratory (“BV Lab”) under OMC’s supervision. The aim of

this testwork was to independently verify the process parameters

developed by the on-site laboratory through extensive

testwork. Based on the test results, the optimized flotation

conceptual engineering design was completed by OMC in June 2021

under the “Sulphide Flotation Circuit Design - Selinsing Gold

Project”, including flotation testwork parameters, process design

criteria, circuit modelling, engineering design brief and

consumables estimates.

Flotation Testwork

Parameters

Diamond drilling was conducted at Buffalo Reef

pits BRC2, BRC3, BRC4 and BR North to provide samples. BV Lab

testwork was designed to ensure repeatability of the on-site

testwork and all flotation tests were carried out in duplicate.

The BV Lab testwork has proved that the

Selinsing onsite laboratory test results are repeatable in a

commercial lab for Fresh and Transition ore (Table 1. Summary of

the BV Lab results), and the onsite laboratory recovery numbers can

be used by OMC with reasonable confidence for engineering design

(refer to news release dated April 27, 2021 “Monument Commences

Flotation Plant Work at Selinsing”).

Table 1: Summary of the BV Lab

results

|

Parameter |

Fresh Average |

Transition Average |

|

|

Site |

BV |

Site |

BV |

|

Mass Pull (%) |

5.1 |

4.1 |

4.5 |

3.3 |

|

Au recovery (%) |

94.3 |

92.6 |

81.8 |

80.0 |

|

Au grade (g/t) |

33.1 |

34.0 |

31.7 |

42.5 |

|

As (%) |

|

5.1 |

|

7.0 |

| |

|

|

|

|

- The fresh ore results report gold

concentrate at an average 34 g/t in line with what was reported at

site in the 30-35 g/t range at a recovery in the low to mid-90s.

The mass pulls were slightly lower.

- The transition ore performed very

well in the BV Lab, with an average concentrate grade of 42.5 g/t

being produced from the two rougher cleaner tests being >10 g/t

higher than the results reported from site. This is linked with

smaller mass pulls as the overall gold recoveries were fairly

similar between the two labs (80% versus 82%).

Testwork results comparison between the

Selinsing on-site lab and the BV Lab are summarized in Table 2:

Testwork comparison between Selinsing on-site and BV Perth

flotation:

- Rougher flotation concentrate was

collected in six fractions. The first rougher concentrate was

consistently high grade and required no cleaning. Rougher

concentrates 2-6 were lower grade and subjected to three stages of

cleaning. Third cleaner concentrate was combined with the first

rougher concentrate to make the final concentrate.

- A minimum of two cleaner stages,

with the ability to direct the material for a third stage in the

event of poor Au grades, was recommended for both ore types based

on the BV Lab results. Adjusting the scheme to increase the mass

pull to ensure the gold grade remains within 30-35 g/t should limit

the need to operate the third stage.

- Recirculating the cleaner tails as

part of the eventual closed-circuit operation will further minimize

the gold lost to tails. The recovery figures from the

closed-circuit mass balance will be used as the basis for the

circuit design.

Table 2: Testwork comparison

between Selinsing on-site and BV Perth

flotation is available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/df990d43-314d-4f3e-8f47-e9dfd0ca01da

Variability Testwork

The Selinsing on-site lab also tested the

flotation scheme on the individual ore zones, which allowed for

benchmarking of both the site and BV Lab composite results against

the projected weighted average. The comparison is below in

Table 3: Final Concentrates Results.

There was better precision when comparing the

calculated weighted average data against both the on-site lab and

the BV Lab composite results for the fresh testwork. When

benchmarked against the calculated weighted average, the transition

ore concentrate grades reported by BV Lab were consistently higher

and mass pulls lower than the site lab data respectively.

Table 3: Final Concentrates Results

|

Ore Source |

Final Concentrate Results |

|

Au grade (g/t) |

Mass Pull (%) |

Recovery (%) |

|

Fresh |

|

|

|

|

BRC2 |

40.35 |

5.15 |

92.34 |

|

BRC3 |

33.78 |

4.53 |

89.07 |

|

BRC4 |

31.90 |

5.02 |

94.69 |

|

BRN |

35.07 |

4.55 |

94.70 |

|

Zone Weighted Average |

35.29 |

4.94 |

92.52 |

|

Site Composite |

33.10 |

5.05 |

94.32 |

|

BV Lab Composite Average |

33.96 |

4.06 |

92.59 |

|

Transition |

|

|

|

|

BRC2 |

40.61 |

4.89 |

82.02 |

|

BRC3 |

33.66 |

3.22 |

69.70 |

|

BRC4 |

32.90 |

2.59 |

74.80 |

|

BRN |

N/A |

N/A |

N/A |

|

Zone Weighted Average |

36.31 |

3.64 |

76.30 |

|

Site Composite Average |

31.65 |

4.49 |

81.80 |

|

BV Lab Composite Average |

42.54 |

3.33 |

79.96 |

Process Plant Engineering

Design

OMC completed the process plant design in early

June 2021, and has submitted the process engineering design

including the process design criteria, major equipment summary,

flowsheet, mass balance and consumables estimates. The battery

limits for the Selinsing Stage 1 sulphide flotation circuit are the

primary mill feed conveyor, the concentrate storage facility and

the tails thickener underflow pump discharge as shown in Figure 1:

Proposed Flotation Circuit Configuration. The process design

has indicated that 6 x 30m3 cells for Rougher, 2 x 20m3 cells for

Cleaner 1, 2 x 4.3m3 cells for Cleaner 2 and 2 x 0.5m3 cells for

Cleaner 3 are to be used.

Further testwork was recommended by OMC to

consider, including:

- Confirmatory locked cycle testing

to be done in parallel with the detailed design to ensure the stage

recovery approach is appropriate;

- The sizing of the thickening and

filtration circuit to be further tested in a pilot plant stage to

ensure it is appropriate;

- Additional filtration testing on

the transition concentrate produced.

Figure 1: Proposed Flotation Circuit

Configuration is available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/ec16fa91-9db7-4aca-982a-dddc4c7450e0

The scientific and technical information in this

press release has been prepared by Charlie Northfield, B.Sc.(Hons),

ACSM, of Monument Mining Limited; reviewed and approved by Fred

Kock (FAusIMM), Principal Metallurgist of Orway Mineral

Consultants, Qualified Person as defined by NI43-101.

About Monument

Monument Mining Limited (TSX-V: MMY, FSE:D7Q1)

is an established Canadian gold producer that owns and operates the

Selinsing Gold Mine in Malaysia. Its experienced management team is

committed to growth and is also advancing the Murchison Gold

Projects comprising Burnakura, Gabanintha and Tuckanarra (20%

interest) in the Murchison area of Western Australia. The Company

employs approximately 200 people in both regions and is committed

to the highest standards of environmental management, social

responsibility, and health and safety for its employees and

neighboring communities.

Cathy Zhai, President and CEOMonument Mining

LimitedSuite 1580 -1100 Melville StreetVancouver, BC V6E 4A6

FOR FURTHER INFORMATION visit the company web

site at www.monumentmining.com or contact:

Richard Cushing, MMY Vancouver T:

+1-604-638-1661 x102 rcushing@monumentmining.com

"Neither TSX Venture Exchange nor its Regulation

Services Provider (as that term is defined in the policies of the

TSX Venture Exchange) accepts responsibility for the adequacy or

accuracy of this release."

Forward-Looking Statement

This news release includes statements containing

forward-looking information about Monument, its business and future

plans ("forward-looking statements"). Forward-looking statements

are statements that involve expectations, plans, objectives or

future events that are not historical facts and include the

Company's plans with respect to its mineral projects and the timing

and results of proposed programs and events referred to in this

news release. Generally, forward-looking information can be

identified by the use of forward-looking terminology such as

"plans", "expects" or "does not expect", "is expected", "budget",

"scheduled", "estimates", "forecasts", "intends", "anticipates" or

"does not anticipate", or "believes", or variations of such words

and phrases or state that certain actions, events or results "may",

"could", "would", "might" or "will be taken", "occur" or "be

achieved". The forward-looking statements in this news release are

subject to various risks, uncertainties and other factors that

could cause actual results or achievements to differ materially

from those expressed or implied by the forward-looking

statements. These risks and certain other factors include,

without limitation: risks related to general business, economic,

competitive, geopolitical and social uncertainties; uncertainties

regarding the results of current exploration activities;

uncertainties in the progress and timing of development activities;

foreign operations risks; other risks inherent in the mining

industry and other risks described in the management discussion and

analysis of the Company and the technical reports on the Company's

projects, all of which are available under the profile of the

Company on SEDAR at www.sedar.com. Material factors and

assumptions used to develop forward-looking statements in this news

release include: expectations regarding the estimated cash

cost per ounce of gold production and the estimated cash flows

which may be generated from the operations, general economic

factors and other factors that may be beyond the control of

Monument; assumptions and expectations regarding the results of

exploration on the Company's projects; assumptions regarding the

future price of gold of other minerals; the timing and amount of

estimated future production; the expected timing and results of

development and exploration activities; costs of future activities;

capital and operating expenditures; success of exploration

activities; mining or processing issues; exchange rates; and all of

the factors and assumptions described in the management discussion

and analysis of the Company and the technical reports on the

Company's projects, all of which are available under the profile of

the Company on SEDAR at www.sedar.com. Although the Company

has attempted to identify important factors that could cause actual

results to differ materially from those contained in

forward-looking statements, there may be other factors that cause

results not to be as anticipated, estimated or intended. There can

be no assurance that such statements will prove to be accurate, as

actual results and future events could differ materially from those

anticipated in such statements. Accordingly, readers should not

place undue reliance on forward-looking statements. The Company

does not undertake to update any forward-looking statements, except

in accordance with applicable securities laws.

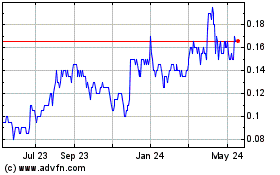

Monument Mining (TSXV:MMY)

Historical Stock Chart

From Nov 2024 to Dec 2024

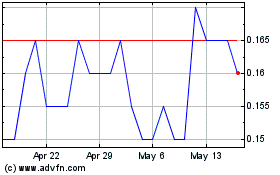

Monument Mining (TSXV:MMY)

Historical Stock Chart

From Dec 2023 to Dec 2024