22 July

2024

CleanTech Lithium PLC ("CleanTech

Lithium", "CTL" or the "Company")

DLE Pilot Plant First Stage Production

Completed, Downstream Process Optimised

with Sample of Battery-Grade Lithium

Produced

CleanTech Lithium PLC (AIM:CTL, Frankfurt:T2N,

OTCQX:CTLHF), an exploration and development

company advancing sustainable

lithium projects in Chile, announces completion of the first stage

of production from the Company´s DLE pilot plant operations and

results from successful downstream process test work to produce

battery-grade lithium carbonate by process partners in North

America.

Highlights:

· An

initial volume of 88m3 of concentrated eluate, which is

the lithium carbonate equivalent (LCE) of approx. one tonne, has

been produced from the Company´s DLE pilot plant in Copiapó, Chile

over an operating period of 384 hours with 14 cycles

completed

·

This completes the first stage of production from the DLE

pilot plant

·

Results show the DLE adsorbent achieved a lithium

recovery rate of approximately 95% from the brine, with total

recovery (adsorption plus desorption) achieving approximately

88%

·

Impurity rejection rates were very high producing a low

impurity eluate conducive to the downstream conversion

process.

· The

concentrated eluate is being shipped in four batches to the

facilities of Conductive Energy in Chicago, USA, for conversion

into battery grade lithium carbonate

|

Shipment

|

Eluate

Volume

|

Eluate Li

Grade

|

LCE

(kg)

|

Shipment

Status

|

|

1

|

24m3

|

2008 mg/L

|

257

|

Arrived process facility

|

|

2

|

24m3

|

2360 mg/L

|

301

|

In Shipment

|

|

3

|

24m3

|

2325 mg/L

|

297

|

In shipment

|

|

4

|

17.5m3

|

2464 mg/L

|

230

|

At departure port

|

|

Targeted

|

90m3

|

2000 mg/L

|

1022

|

|

|

Total Achieved

|

88m3

|

2289 mg/L

|

1085

|

|

Table 1:

Status of concentrated eluate from pilot plant first stage

production

·

Conductive Energy completed test-work on a 200L sample of

concentrated eluate shipped in May 2024 to optimise the downstream

process before receiving the larger volume shipments

· The

conversion test-work produced multiple samples of lithium carbonate

with 99.75% lithium carbonate purity demonstrating that the process

achieves targets and is repeatable

· The

result is a first confirmation that a process has been developed

that will efficiently produce battery-grade lithium for the Laguna

Verde project from pilot scale DLE eluate

·

CleanTech Lithium continues to be a leader in exploration and

development of DLE based projects in Chile and this pilot scale

production will provide large test samples of lithium carbonate to

potential offtake partners seeking product

qualification.

·

Subject to the completion of the re-injection well in

September, the reserve report for Laguna Verde is scheduled to be

completed by Montgomery and Associates in October 2024.

Steve Kesler,

Executive Chairman and Interim CEO, of CleanTech Lithium PLC,

said:

"We are very

pleased by these results as it shows we can produce battery-grade

lithium with low impurities from our Laguna Verde brine project.

Working with our partners on the downstream process, Forward Water

and Conductive Energy, we can now demonstrate the entire DLE

process from brine to final lithium product.

"The

optimised downstream process will now be applied to the initial

volume of 88m3 of concentrated eluate, or approximately

1 tonne of LCE, produced from the first stage of production from

our DLE pilot plant. This will produce significant test sample

volumes of battery-grade lithium carbonate for commencement of

testing with potential strategic partners. This is important whilst

the Chilean government is reviewing the feasibility of lithium

projects to identify the most advanced companies in Chile and if

they are to reach their target of having three to four new lithium

projects in development by 2026."

Further

Information

Pilot Plant in Copiapó First Stage Production

Completed

The Company´s DLE pilot plant is

in Copiapó, Chile,

approximately 275km from Laguna Verde. The plant finished

commissioning in late March 2024 and up until mid-June a total

volume of 1196m3 of brine from the Laguna Verde project

was processed in the plant with a total of 14 cycles completed.

Each cycle represents a volume of brine being fed first through

filtration to remove suspended solids, then into DLE columns which

are filled with adsorbent designed to be selective for lithium

molecules. Lithium, as lithium chloride, is adsorbed from the

brine, before desorption with water to create a purified lithium

chloride eluate. A reverse osmosis (RO) unit at the DLE pilot

plant then concentrates the eluate by extracting

approximately 75% of the water to form a concentrated

eluate.

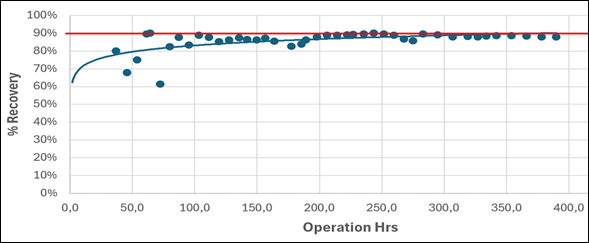

Averaged across the 14 cycles, the recovery

rate achieved by adsorption of lithium by the adsorbent was 95% and

the recovery rate of desorption from the adsorbent was 93%. The

total recovery rate averaged 88% and was highly consistent as shown

in Figure 1. The temperature of the brine and desorption water,

using the average ambient temperature in Copiapó during the March

to June period of operation, was in the range of 20oC to

25oC, which did not significantly affect the recovery

achieved.

Figure 1:

Pilot Plant Total Recovery Rate

The eluate production rate was relatively

stable after the initial ramp up period achieving an average of 2.8

kg LCE per hour. The design of the plant is 1 tonne per month of

LCE based on designed monthly operating schedule of 360 hours. Due

to budget and volume considerations, the plant was run for 384

hours for the first stage of planned operation producing a total of

1.085 tonnes of LCE as eluate. Based on the hourly production rate

this met and exceeded the design capacity of the plant.

Figure 2:

Pilot Plant Production Rate (Kg LCE/hr in Eluate)

Selectivity of the adsorbent is another key

performance parameter for a DLE operation. DLE

primarily acts as a purification stage, recovering lithium chloride

from the brine whilst rejecting other impurities. For all the major

ions in the brine, apart from boron, the rejection rate was very

high as shown in Fig. 3 below. More cycles will further validate

this performance. The quality of the eluate was consistent over the

first stage of production with the low level of impurities

facilitating downstream conversion.

Figure 3: DLE

Performance - Rejection of Major Impurities

After completion of the DLE stage,

the eluate is concentrated using a reverse osmosis (RO) unit at the

pilot plant. On completion of both stages the lithium grade in the

purified lithium chloride eluate is over ten times higher than the

feed brine. The concentrated eluate was then loaded into a

flexitank in a standard shipping container and transported to the

port of Caldera for shipment to North America.

Downstream Processing into Battery Grade Lithium

Carbonate: Test-work Completed

For the conversion of the

concentrated lithium chloride eluate into battery grade lithium

carbonate, CleanTech Lithium has engaged a leading lithium

processing company, Conductive Energy, based in Alberta, Canada,

which has facilities in Chicago, USA, with key downstream

processing units shown in Figure 4 below. The status of the concentrated

eluate shipment is shown in Table 1 with processing to commence in

August 2024.

Figure 4: Conductive Energy Carbonation Reactor Tank and

Equipment for Washing, Filtering & Drying

In May 2024 CTL air-freighted a 200L

sample of concentrated eluate from the pilot plant to Conductive

Energy to undertake test-work to optimise the conversion process.

The process steps are shown in Figure 5, involving a further stage

of RO, before using Forward Osmosis (FO) to achieve a very high

level of concentration. Ion exchange (IX) is used to remove

calcium, magnesium, and boron. The final steps are carbonation and

then washing, filtration and drying to produce a battery grade

product. Conductive Energy´s approach is to simplify the process

that achieves maximum yield by minimizing process steps and, where

losses occur, produce fluids that are easily recycled to further

maximize yield.

Figure 5: Conductive Energy Conversion

Process

Reverse Osmosis and Forward Osmosis

The increase in eluate and lithium

concentration in the R/O and F/O stages are shown in Table 2 below.

R/O is effective for concentration until Total Dissolved Solids

(TDS) reach the level of approximately 60,000 - 70,000 TDS, after

which it is increasingly energy intensive and costly. F/O is highly

effective in further concentration to the required lithium grade

for carbonation, in this case 18,000mg Li/L (or 1.8% Lithium). The

F/O unit is provided by Forward Water Technology, another Canadian

company based in Ontario. F/O achieves a high concentration factor

with much lower energy use than the alternative of using a

mechanical evaporator, while being highly suitable for utilising

solar thermal as the energy source to power the F/O process.

|

Parameter

|

Unit

|

Concentrated Eluate

|

R/O

Concentrate

|

F/O

Concentrate

|

|

Lithium (Li)

|

mg/L

|

2,194

|

5,700

|

18,000

|

|

Chloride (Cl)

|

mg/L

|

11,039

|

37,000

|

110,000

|

|

Boron (B)

|

mg/L

|

411

|

850

|

1,700

|

|

Calcium (Ca)

|

mg/L

|

7

|

29

|

85

|

|

Magnesium (Mg)

|

mg/L

|

14

|

50

|

150

|

|

Sodium (Na)

|

mg/L

|

134

|

400

|

1,400

|

|

Sulphate (SO4)

|

mg/L

|

103

|

120

|

330

|

|

Total Dissolve Solids

(TDS)

|

mg/L

|

19,260

|

62,000

|

190,000

|

|

Volume

|

L

|

215.5

|

66.3

|

13.9

|

|

Reduction in Volume

|

%

|

|

69.3%

|

93.5%

|

|

Laboratory

|

|

ALS Chile

|

Lambton.Scientific

|

Lambton.Scientific

|

Table 2: Results from concentration of Laguna Verde eluate

through R/O followed by F/O

Ion

Exchange to Remove Impurities

Ion exchange (IX) was used for

removal of calcium and magnesium, which achieved 85% and 87%

reductions respectively. While feed concentrations

were low, 100% of barium and manganese were also removed in the

same process. Additional optimization is possible with potential

for further calcium removal. Lithium loss was low at

3%.

Conductive then applied its optimised IX for

removal of boron. This was highly effective achieving

>99.5% removal of boron. However, there was a 22% loss of

lithium to the regeneration fluid. This would be recaptured by

recycling the regeneration fluid to the F/O feed which was not

implemented for this small-scale test-work. The lithium loss from

the boron IX is expected to be reduced (recovered) to a steady

state loss rate of about 3%.

Carbonation and Battery Grade Lithium Sample

The carbonation test-work achieved an

exceptional yield of 96% of the theoretical maximum. The final

product, after the wash procedure, was 99.75% lithium carbonate

purity as shown in Table 3. Further optimisation of the

washing stage is planned in order to reduce impurities to the

greatest extent possible and therefore maximise the value of the

battery grade product.

Table 3:

Process test-work lithium carbonate sample

purity Fig.

6: Test-work sample

Additional

Operations

Laguna Verde Reserve Report

Update

The next stage of resource evaluation at the

Laguna Verde project is to produce an updated JORC compliant

resource and a reserve report based on converting a portion of

resources into reserves. The management of the resource

evaluation programme and reserve report is led by Montgomery and

Associates, a leading hydrogeology consultant with extensive

experience in resource evaluation of lithium brine projects

in Chile and Argentina. Reserve estimation will feed

directly into the Pre-Feasibility Study which is targeted for later

this year.

The reserve calculation requires the completion

of pumping tests and a re-injection well at the project which is

scheduled for September 2024, when drilling equipment can be

re-mobilised after the current winter break in operations. Subject

to the completion of the re-injection well in September, the

reserve report is scheduled to be completed by Montgomery and

Associates in October 2024.

Competent

Persons

The following professional acts as qualified

person, as defined in the AIM Note for Mining, Oil and Gas

Companies (June 2009) and JORC Code (2012):

Marcelo Bravo: Chemical Engineer (Universidad

Católica del Norte), has a Master's Degree in Engineering Sciences

major in Mineral Processing, Universidad de Antofagasta. He

currently works as a Senior Process Consulting Engineer at the

Ad-Infinitum company. Mr Bravo has relevant experience in

researching and developing potassium, lithium carbonate, and solar

evapo-concentration design processes in Chile, Argentina, and

Bolivia. Mr Bravo, who has reviewed and approved the information

contained in the chapters relevant to his expertise contained in

this announcement, is registered with No. 412 in the public

registry of Competent Persons in Mining Resources and Reserves per

the Law of Persons Competent and its Regulations in force in Chile.

Mr Bravo has sufficient experience relevant to the metallurgical

tests and the type of subsequent processing of the extracted brines

under consideration and to the activity being carried out to

qualify as a competent person, as defined in the JORC Code. Mr

Bravo consents to the inclusion in the press release of the matters

based on his information in the form and context in which it

appears.

The

information communicated within this announcement is deemed to

constitute inside information as stipulated under the Market Abuse

Regulations (EU) No 596/2014 which is part of UK law by virtue of

the European Union (Withdrawal) Act 2018. Upon publication of this

announcement, this inside information is now considered to be in

the public domain. The person who arranged for the release of this

announcement on behalf of the Company was Gordon Stein, Director

and CFO.

|

For

further information contact:

|

|

|

CleanTech Lithium PLC

|

|

|

Steve Kesler/Gordon Stein/Nick

Baxter

|

Jersey office: +44 (0) 1534 668

321

Chile office:

+562-32239222

|

|

|

Or via Celicourt

|

|

Celicourt Communications

Felicity Winkles/Philip Dennis/Ali

AlQahtani

|

+44 (0) 20 7770 6424

cleantech@celicourt.uk

|

|

Beaumont Cornish Limited (Nominated Adviser)

Roland Cornish/Asia

Szusciak

|

+44 (0) 20 7628 3396

|

|

Fox-Davies Capital Limited (Joint Broker)

Daniel Fox-Davies

|

+44 (0) 20 3884 8450

daniel@fox-davies.com

|

|

Canaccord Genuity (Joint Broker)

James Asensio

|

+44 (0) 20 7523 4680

|

Beaumont Cornish Limited ("Beaumont Cornish") is the Company's

Nominated Adviser and is authorised and regulated by the FCA.

Beaumont Cornish's responsibilities as the Company's Nominated

Adviser, including a responsibility to advise and guide the Company

on its responsibilities under the AIM Rules for Companies and AIM

Rules for Nominated Advisers, are owed solely to the London Stock

Exchange. Beaumont Cornish is not acting for and will not be

responsible to any other persons for providing protections afforded

to customers of Beaumont Cornish nor for advising them in relation

to the proposed arrangements described in this announcement or any

matter referred to in it.

Notes

CleanTech Lithium (AIM:CTL,

Frankfurt:T2N, OTCQX:CTLHF) is an exploration and development

company advancing sustainable lithium projects

in Chile for the clean energy transition. Committed to

net-zero, CleanTech Lithium's mission is to produce material

quantities of sustainable battery grade lithium products using

Direct Lithium Extraction technology powered by renewable energy.

The Company plans to be a leading supplier of 'green' lithium to

the EV and battery manufacturing market.

CleanTech Lithium has two key

lithium projects in Chile, Laguna Verde and Viento Andino, and hold

licences in Llamara and Salar de Atacama, located in the

lithium triangle, a leading centre for battery grade lithium

production. The two major projects: Laguna Verde and Viento

Andino are situated within basins controlled by the Company,

which affords significant potential development and operational

advantages. All four projects have direct access to existing

infrastructure and renewable power.

CleanTech Lithium is committed to

using renewable power for processing and reducing the environmental

impact of its lithium production by utilising Direct Lithium

Extraction with reinjection of spent brine. Direct Lithium

Extraction is a transformative technology which removes lithium

from brine, with higher recoveries than conventional extraction

processes. The method offers short development lead times with no

extensive site construction or evaporation pond development so

there is minimal water depletion from the

aquifer. www.ctlithium.com

**ENDS**