ASM launches PE2O8 silicon carbide epitaxy system

01 October 2024 - 4:00AM

UK Regulatory

ASM launches PE2O8 silicon carbide epitaxy system

Raleigh, NC, USA

September 30, 2024

New system extends ASM’s portfolio of

industry benchmark single wafer silicon carbide epitaxy systems,

the 6” PE1O6 and 8” PE1O8 systems, with a higher throughput, lower

cost of ownership, dual chamber, single wafer, 6” and 8”

compatible, silicon carbide epitaxy system.

Today at the 2024 International Conference on

Silicon Carbide and Related Materials, ASM International N.V.

(Euronext Amsterdam: ASM) introduced the PE2O8 silicon carbide

epitaxy system, a new, dual chamber, platform for silicon carbide

(SiC) epitaxy (Epi). Designed to address the needs of the advanced

SiC power device segment, the PE2O8 is the benchmark epitaxy system

for low defectivity, high process uniformity, all with higher

throughput and low cost of ownership needed to enable broader

adoption of SiC devices.

As the general electrification trend drives more

power device manufacturers to utilize SiC for a growing number of

high-power applications (such as for electric vehicles, green

power, and advanced data centers) the expanded demand and

requirements for lower cost for SiC is causing a transition from 6”

to 8” SiC substrates. At the same time, SiC device manufacturers

are designing higher power devices that will benefit from better

SiC epitaxy.

Utilizing a unique design, the dual chamber

PE2O8 system deposits SiC with ultra precise control, enabling

benchmark higher yield and higher throughput. The highly compact,

dual chamber design enables high productivity and low total costs

of operation. Additionally, the system features an easy preventive

maintenance approach helping to increase uptime and reduce the

occurrence of unscheduled downtime. System deliveries have been

ongoing to multiple customers globally, among them leaders in SiC

power device manufacturing.

“We are at a critical inflection for silicon

carbide power products, as our customers transition from 6” to 8”

wafers”, said Steven Reiter, Corporate Vice President, and business

unit head of Plasma and Epi at ASM. “Delivering a high-quality

epitaxy process on larger wafers with defectivity control is

critical, and we have been the industry benchmark for process

uniformity with our novel chamber design. We have now extended our

system capability to improve our process control and our value for

customers with lower cost of ownership.”

Since 2022, ASM, through its new SiC Epi product

unit has been developing and refining its single wafer SiC epitaxy

system. With the structurally higher demand for electric vehicles

and improvement of the overall SiC wafer and device yield, the

equipment market for SiC epitaxy has grown substantially in recent

years.

About ASM International

ASM International N.V., headquartered in Almere, the

Netherlands, and its subsidiaries design and manufacture equipment

and process solutions to produce semiconductor devices for wafer

processing, and have facilities in the United States, Europe, and

Asia. ASM International's common stock trades on the Euronext

Amsterdam Stock Exchange (symbol: ASM). For more information, visit

ASM's website at www.asm.com.

Contact

Investor and media relations

Victor Bareño

T: +31 88 100 8500

E: investor.relations@asm.com |

Investor relations

Valentina Fantigrossi

T: +31 88 100 8502

E: investor.relations@asm.com |

- 20240930 ASM launches PE2O8 silicon carbide epitaxy system

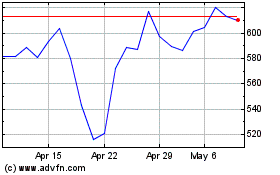

ASM International NV (TG:AVS)

Historical Stock Chart

From Jan 2025 to Feb 2025

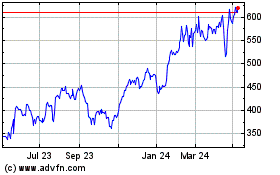

ASM International NV (TG:AVS)

Historical Stock Chart

From Feb 2024 to Feb 2025