Marimaca Copper Corp. (“Marimaca Copper” or the “Company”) (TSX:

MARI) is pleased to announce results of the Phase 6 Metallurgical

testing program (the “Phase 6 Program” or the “Program”) for the

Company’s flagship Marimaca Oxide Copper Project (“the MOD” or “the

Project”), located in northern Chile.

The Phase 6 program was designed to evaluate

leaching conditions to optimize acid consumption, recoveries and

leaching efficiency to be incorporated into the ongoing Definitive

Feasibility Study (“DFS”).

Highlights

-

Comprehensive 5 column-test program evaluating the impact

of curing, leaching rates and acid concentration in solution on

acid consumption, recoveries and impurities

generation

-

Significantly improved acid consumption based on

optimization of leaching conditions

- Net acid

consumption of 30.6kg/t from experimental samples – an approximate

25% reduction from the 40.6kg/t derived from previous metallurgical

campaigns

- Provides

further confidence in expected acid consumption with clear

potential to enhance operating cost profile for the

DFS

- Confirms

average copper recovery of 74.9% - in-line with previous results

from metallurgical campaigns (Phases 1-5)

-

Flexibility for further reductions in acid consumption with

relatively low recovery losses

- Program

completed with recycled sea-water sourced from Marimaca’s intended

water supplier under its water option agreement to accurately

reflect process water to be utilized at the Project

- Further

de-risking of the Marimaca metallurgy – allows for improved

predictability of metallurgical performance during

operations

- Results

will be incorporated into the final geo-metallurgical model to be

utilized in the DFS which will define, at high resolution, the

metallurgical performance of each ore-feed type in the

DFS

- Results

demonstrate the self-regulation of impurities in the leaching cycle

which allows for simple SX-EW process design and capital efficiency

for the planned DFS

Hayden Locke, President and CEO of

Marimaca Copper, commented:

“We are pleased with the Phase 6 metallurgical

results and particularly the implications for acid consumption

optimization in the DFS and in future operations.

Acid consumption is a key component of our

operating costs, and fluctuations in acid price were identified as

a core external factor in our projected operating margins as we

move towards first copper. The results from this program show,

firstly, that our base case assumptions, with respect to acid

consumption, can be materially reduced via simple changes to our

operational approach with no significant impact to our expected

recoveries.

Secondly, the testing highlights that we have

further flexibility to reduce acid consumption, with relatively

small recovery losses. From my perspective, this is the most

important outcome from the testing, because it allows us to make

operational changes to preserve margin and cashflow during periods

of high acid prices, which increases the resilience of the Project

to external shocks.

“The Marimaca Project continues to demonstrate

unique positioning in the copper development space. We are excited

to move through the final development milestones as we rapidly

advance toward first copper.”

Program Overview

Phase 6 Metallurgy comprised of a set of

leaching tests in five 1m high, 6-inch diameter columns. The sample

set consisted of green oxides comprised 50% brochantite/atacamite

and 50% chrysocholla with a total sample size of 240kg which was

crushed at P90 ½”, consistent with previous metallurgical test-work

phases. The sample was subjected to separation by sieving, in the

½”, ¼”, 10 and -10 Tyler meshes, and then, from each granulometric

fraction, a sample size was taken as required to form the program

design cut under the standardized “cut by mono size” technique.

Process seawater used in the column tests was

sourced from the counterparty to Marimaca’s water option agreement

to accurately represent the industrial process water that will be

used at the Marimaca operation (see Water Option press release

dated November 7, 2022). The leaching conditions were focused on

variables to optimize acid consumption. The two variables

controlled were acid dosing in curing step, and the Leaching Ratio

(m3 irrigate solution/tonne ore). The head grade of the ore, the

grade of ripios resulting from leaching, the initially acidified

seawater, the pregnant leaching solution (“PLS”) and the raffinate

solutions were each characterized by the elements for which the

evolution of impurities was monitored. The evolution of impurities

was quantified by determining the concentration in the PLS

solutions of the following elements: FeT, Al, Mg, Mn, Na, Cl- and

SO4= and Cu. Cu was removed from the PLS solutions by solvent

extraction (SX), at the end of each leaching cycle.

Column Tests

Results were evaluated from two leaching cycles

over five columns. In both irrigation cycles, the tests operate in

a closed circuit with a volume of irrigation solution equivalent to

10 days of operation, which, at an irrigation rate of 10 L/h/m2 is

equivalent to a leaching rate of 0.93m3/to (approximately) for each

cycle and 1.86 m3/t in total.

Column 1 (C-1) and Column 2 (C-2) were leached

with seawater and acid in the first cycle, then the PLS obtained

was treated by solvent extraction and the raffinate produced was

used for the second leaching cycle. The PLS from the second cycle

of each column (C-1 and C-2) was then treated by solvent extraction

(SX) and both raffinate solutions produced were mixed and used as

the leaching solution for Column 3 (C-3). The post-SX raffinate of

the C-3 PLS was used to leach Column 4 (C-4) and similarly for C-4

to Column 5 (C-5).

Each column was agglomerated and cured under

identical conditions, summarized in Table 3.

Table 1. Sample Set Mass

Allocation

|

Usage |

Unit |

Value |

|

Columns |

kg |

150 (5x30kg) |

|

Head Grade |

kg |

10 |

|

Back Up |

kg |

80 (4x20kg) |

|

|

Table 2. Particle Size Distribution of

Sample Set

|

Granulometric Fraction |

Mass (kg) |

|

C-1 |

C-2 |

C-3 |

C-4 |

C-5 |

Backup |

|

1/2" |

3.25 |

3.25 |

3.25 |

3.25 |

3.25 |

8.66 |

|

1/4" |

9.51 |

9.51 |

9.51 |

9.51 |

9.51 |

25.37 |

|

+10 # |

8.62 |

8.62 |

8.62 |

8.62 |

8.62 |

22.97 |

|

-10 # |

8.62 |

8.62 |

8.62 |

8.62 |

8.62 |

22.99 |

|

TOTAL |

30.0 |

30.0 |

30.0 |

30.0 |

30.0 |

80.0 |

|

|

Table 3. Agglomeration and Curing

Conditions

|

Parameter |

Unit |

Value |

|

Moisture (Seawater) |

% |

6 |

|

Acid Dose Curing |

kg/ton |

20 |

|

Curing Time |

days |

3 |

|

|

Following the irrigation cycle in each column,

the solution contained inside the column was allowed to drain, and

the ripios were washed by passing a seawater solution at pH 3 at an

irrigation rate of 10 L/h/m2 for 24 hours. The drained volume was

measured and analyzed for the same elements considered in the

analysis of the PLS solutions.

Following drainage of the washing stage, the

ripios were unloaded from the respective columns and the wet and

dry weights were recorded. A subsample equal to a quarter of the

total ripios sample was sent for chemical assays following

separation.

Results

Acid Consumption

Acid consumption was measured by both total acid

consumption (CAB) and net acid consumption (CAN). CAN reflects acid

consumed only by the gangue minerals (carbonate, aluminium, total

iron, magnesium) given raffinate is recirculated with the acid

consumed by copper post the SX stage. Geomet 6 was designed to

evaluate the optimization of acid consumption by evaluating three

variables: acid curing rate (20kg/t), acid concentration (10gpl)

and leaching ratio (1.86m3/t).

Results of the column test acid consumption is

presented in Figure 1. Average CAB was 36.91kg/t while average CAN

was 30.63kg/t.

Figure 1. Acid Consumption – Columns

1-5

By controlling the noted variables, acid

consumption can be optimized given the sequential nature of

consumption by each of the gangue minerals – for example, the

majority of acid consumption in the curing stage is driven by

carbonate, followed by copper, aluminum, total iron and magnesium

predominantly during the leaching cycle.

Copper Recovery

Table 4 and Figure 2 show the calculated head

and head/ripio base copper recovery by columns. The average copper

recovery of the 5 columns per head calculated was 74.9%, while the

recovery per head/ripios was 73.0%. Results are in-line with

expected results based on previous test-work and demonstrate that

copper recovery can be maintained while optimizing the variables

that reduce acid consumption and impurities generation.

Table 4. Column Recoveries

|

Column |

Analyzed Cu Head Grade |

Calculated Cu Head Grade |

Fine Cu Analyzed Head Grade |

Copper Leached |

Copper in Ripios |

Copper Calculated Head |

Recovery Calculated from Head(R CC) |

Recovery Calculated from Ripios(R C/R) |

|

(N°) |

(%) |

(%) |

(g) |

(g) |

(g) |

(g) |

(%) |

(%) |

|

C-1 |

0.620 |

0.568 |

186.00 |

122.64 |

47.74 |

170.4 |

72.0 |

74.3 |

|

C-2 |

0.620 |

0.628 |

186.00 |

139.47 |

49.03 |

188.4 |

74.0 |

73.6 |

|

C-3 |

0.620 |

0.638 |

186.00 |

143.68 |

47.74 |

191.4 |

75.1 |

74.3 |

|

C-4 |

0.620 |

0.718 |

186.00 |

166.72 |

48.83 |

215.4 |

77.4 |

73.7 |

|

C-5 |

0.620 |

0.815 |

186.00 |

186.3 |

58.05 |

244.5 |

76.2 |

68.8 |

|

|

Figure 2. Column Recoveries

Impurities Generation

The column tests were evaluated to determine the

experimental evolution of impurities generation vs. the theoretical

evolution of impurities generation to determine the equilibrium

point of the system. This was studied to determine the expected

performance of the SX-EW plant and its ability to handle the

solution generation from leaching of Marimaca ores.

Results shows that as the recirculation of

leaching solution occurs, as is the case in industrial operations,

the capacity of the system to dissolve impurities decreases, which

indicates that the system self-regulates before any impurities

mitigation is required in the SX-EW process design. In industrial

terms, by feeding the heap with fresh ore, the curing acid and the

leaching solutions will dissolve new impurities, but simultaneously

others will precipitate in the heap, and the system will reach

equilibrium.

This concept is demonstrated in Figure 3.

Whereby results from Geomet 6 show the experimental sulfate

concentration in each cycle deviates and plateaus relative to the

theoretical sulfate concentration with the correlation coefficient

of the experimental results of 0.9992. When projecting the

experimental curve 3 additional cycles, it can be observed that the

sulfate saturation level is approximately 147 gpl.

Table 5. Evolution of Impurities

Concentration in PLS solution

|

Column |

FeT |

Al+3 |

Mg+2 |

Mn+2 |

Na+ |

Cl- |

SO4= |

|

(Nº) |

(g/L) |

(g/L) |

(g/L) |

(g/L) |

(g/L) |

(g/L) |

(g/L) |

|

C-1 |

6,54 |

3,14 |

3,49 |

0,25 |

13,15 |

27,55 |

46,21 |

|

C-2 |

6,18 |

3,03 |

3,21 |

0,20 |

12,55 |

26,67 |

44,76 |

|

C-3 |

9,61 |

5,40 |

4,03 |

0,37 |

13,42 |

28,81 |

74,98 |

|

C-4 |

13,50 |

6,99 |

5,61 |

0,57 |

16,05 |

31,43 |

103,37 |

|

C-5 |

17,52 |

10,34 |

6,80 |

0,80 |

18,53 |

38,16 |

120,32 |

|

|

Figure 3. Evolution of Sulfate

Concentration in PLS solution

Appendix: Chemical Characterization of

Experimental Inputs

Below the chemical characterization of the head

sample, the seawater input, and the leaching solution are

presented.

Table 6. Chemical Characterization of

Head Sample

|

Elements |

CuT(%) |

FeT(%) |

|

Al(%) |

Mg(%) |

|

Mn(%) |

Na(%) |

CO3(%) |

Cl-(%) |

SO4=(%) |

|

Head Grade |

0.641 |

7.66 |

|

6.72 |

1.05 |

|

0.07 |

3.09 |

0.63 |

0.25 |

0.15 |

|

|

Table 7. Chemical Characterization of

Seawater Used

|

Element |

Cu+2(mg/L) |

|

FeT(mg/L) |

Al+3(mg/L) |

Mg+2(g/L) |

Mn+2(mg/L) |

Na+(g/L) |

Cl- (g/L) |

SO4=(g/L) |

pH |

|

Seawater |

0,00 |

|

0,90 |

1,70 |

1,44 |

ND |

11,33 |

23,21 |

2,10 |

7,60 |

|

|

Table 8. Chemical Characterization of the

Initial Leaching Solution (for Columns C-1 and C-2)

|

|

Cu+2 |

FeT |

Fe+2 |

Al+3 |

Mg+2 |

Mn+2 |

Na+ |

Cl- |

H+ |

pH |

SO4= |

|

(mg/L) |

(mg/L) |

(mg/L) |

(mg/L) |

(g/L) |

(mg/L) |

(g/L) |

(g/L) |

(g/L) |

|

(g/L) |

|

Leach Solution |

0,00 |

0,90 |

ND |

1,70 |

1,44 |

ND |

11,33 |

22,10 |

9,38 |

0,75 |

9,94 |

|

|

Qualified Person

The Qualified Person for technical information

in this news release is Gabriel Vera, an extractive metallurgical

engineer with over 35 years of experience. Mr. Vera is a registered

member of the Comision Minera (Chilean Mining Commission) and a

Qualified Person for the purposes of NI 43-101.

The QP confirms they have reviewed and approved

the scientific and technical information related to metallurgy in

this news release.

Contact InformationFor further

information please visit www.marimaca.com or contact:

Tavistock +44 (0) 207 920

3150Gareth Tredway / Adam

Baynesmarimaca@tavistock.co.uk

Forward Looking Statements

This news release includes certain

“forward-looking statements” under applicable Canadian securities

legislation. There can be no assurance that such statements will

prove to be accurate, and actual results and future events could

differ materially from those anticipated in such statements.

Forward-looking statements reflect the beliefs, opinions and

projections on the date the statements are made and are based upon

a number of assumptions and estimates that, while considered

reasonable by Marimaca Copper, are inherently subject to

significant business, economic, competitive, political and social

uncertainties and contingencies. Many factors, both known and

unknown, could cause actual results, performance or achievements to

be materially different from the results, performance or

achievements that are or may be expressed or implied by such

forward-looking statements and the parties have made assumptions

and estimates based on or related to many of these factors. Such

factors include, without limitation: risks related to share price

and market conditions, the inherent risks involved in the mining,

exploration and development of mineral properties, the

uncertainties involved in interpreting drilling results and other

geological data, fluctuating metal prices, the possibility of

project delays or cost overruns or unanticipated excessive

operating costs and expenses, uncertainties related to the

necessity of financing, uncertainties relating to regulatory

procedure and timing for permitting reviews, the availability of

and costs of financing needed in the future as well as those

factors disclosed in the annual information form of the Company

dated March 27, 2023 and other filings made by the Company with the

Canadian securities regulatory authorities (which may be viewed

at www.sedar.com). Statements regarding the Company’s planned

DFS on the Project are forward-looking information and may not be

realized. Readers should not place undue reliance on

forward-looking statements. Marimaca Copper undertakes no

obligation to update publicly or otherwise revise any

forward-looking statements contained herein whether as a result of

new information or future events or otherwise, except as may be

required by law.

Neither the Toronto Stock Exchange nor the

Canadian Investment Regulatory Organization accepts

responsibility for the adequacy or accuracy of this

release.

Photos accompanying this announcement are available

at:https://www.globenewswire.com/NewsRoom/AttachmentNg/ac8d7b9a-d2b9-4fec-84aa-d78fa8fc60cc

https://www.globenewswire.com/NewsRoom/AttachmentNg/122b22f6-613a-405e-a803-d1cbe5767c3f

https://www.globenewswire.com/NewsRoom/AttachmentNg/e4807430-c676-4e69-b4eb-a23f33ce194a

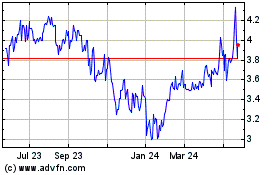

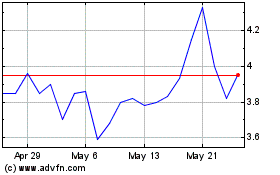

Marimaca Copper (TSX:MARI)

Historical Stock Chart

From Jan 2025 to Feb 2025

Marimaca Copper (TSX:MARI)

Historical Stock Chart

From Feb 2024 to Feb 2025