PRESS RELEASE

Decarbonizing the aviation sector: Global

Bioenergies extends its technological process to the production of

e-SAF

-

a unique e-SAF with a record selectivity rate of 95%

compared to existing technologies

-

a complementary approach to ASTM-certified SAF technology,

substituting a plant-based resource for a synthetic

resource

Evry, 10 July 2024 – 05:45

p.m.: Global Bioenergies announced today that it has

adapted its process for the conversion of plant resources into

Sustainable Aviation Fuels (SAF) to produce e-SAF, using acetic

acid as a resource.

e-SAFs are derived from the combination of (i)

CO2 and (ii) hydrogen produced from renewable electricity: acetic

acid can be produced from these two elements alone. e-SAFs maximize

decarbonation impacts and offer an alternative to bio-SAFs, whose

production relies on the use of plant resources.

The e-SAF approach developed by Global

Bioenergies stands out for its selectivity of over 95%, meaning

that more than 95% of the molecules resulting from the process can

be marketed as jet fuel. This selectivity exceeds that of other

existing e-SAF technologies.

SAFs and e-SAFs are regulated by the European

Union's ReFuelEU Aviation regulation. By 2030, aircrafts taking off

from European airports will be required to carry on average in

their tank:

- 4.8% bio-SAF, produced from plant resources,

mandate which includes Global Bioenergies' bio-SAF process from

plant resources, and

- 1.2% e-SAF produced from CO2 and low-carbon

electricity, mandate which includes Global Bioenergies’ e-SAF

process.

Marc Delcourt, co-founder and CEO of

Global Bioenergies, commented: "The prospect of producing

not only bio-SAFs, but also e-SAFs, adds another string to our bow.

In regions where plant resources are abundant (USA, Brazil,

South-East Asia...), our bio-SAF approach will have an important

role to play. In regions where plant resources are only available

in limited quantities, our e-SAF approach will be deployed

primarily: this is the case in Europe and North Asia in

particular."

Eva van Mastbergen, Team Lead R&D at

SkyNRG, said: "Given the growing global demand for SAF,

driven by the ReFuelEU mandate and rising SAF ambitions, the

industry must increase production and diversify technologies to

convert various sustainable feedstocks into SAF. Following our

successful collaboration on ASTM qualification of Global

Bioenergies’ SAF platform, we commend recent innovations supporting

both bio-based SAF and e-SAF, advancing a more sustainable aviation

industry.”

A new resource for the process: acetic

acid

Acetic acid (“AcOH”) is well known to the

general public as the acid in vinegar.

In summary, it involves feeding the bacterial

strains producing isobutene (then transformed into SAF by simple

oligomerization), no longer with plant resources, but with acetic

acid.

Most of the 5 million tonnes of acetic acid

produced every year is obtained by combining methanol and carbon

monoxide, which can both be produced from CO2 and hydrogen.

(Hydrogen can be produced by electrolysis of water using low-carbon

electricity).

This approach is therefore in line with the

specifications of e-SAFs, defined by the use of CO2 and low-carbon

electricity.

AcOH, a new raw material for

microorganisms

Microorganisms naturally break down sugar

(usually six-carbon) into acetic groups (two-carbon), which are

then converted into numerous other molecules useful to life (fatty

acids and amino acids, in particular). Although AcOH is well known

to micro-organisms, which produce it endogenously, these

micro-organisms are not naturally organized to use it as a resource

massively supplied exogenously.

It was therefore necessary to modify

isobutene-producing strains so that they could accept AcOH, which

has been successfully achieved in recent months.

e-AcOH, a resource that could soon be

available on a large scale

A major player in the industrial production of

AcOH is already producing e-AcOH based on CO2 captured from

industrial effluent gases, combined with low-carbon hydrogen.

What stage of development has the e-SAF

process reached?

The process is now moving from proof of concept

to pre-industrial development.

At the same time, the performance of Global

Bioenergies' bio-SAF process has improved significantly in recent

months, and this progress has been transposed to the pilot scale.

It will continue to improve over the coming months, to approach the

theoretical optimum. The progress made on the bio-SAF process will

be transposed to the performance of the e-SAF process.

The competitive advantages of Global

Bioenergies' e-SAF process

Today, there is no industrial-scale production

of e-SAF, and no aircraft has yet flown fully on e-SAF.

Two families of e-SAF production processes are

currently being developed by various players. Both are based on

chemical approaches:

- The first uses the Fischer-Tropsch synthesis

process,

- The second involves the production of

e-methanol, which is then converted into e-SAF.

In both cases, the selectivity of the process to

SAF is lower than Global Bioenergies’ e-SAF process, meaning a

larger fraction of side-products will be marketed as e-gasoline or

e-diesel, at a lower price.

Global Bioenergies' e-SAF process provides an

answer here: over 95% of the products from its process correspond

to the aviation stream, which would benefit the industrial

profitability of the corresponding plants.

Conclusion

This breakthrough in biology paves the way to a

new e-SAF process, distinguished from other e-SAF technologies by

its very high selectivity. It adds a valuable string to Global

Bioenergies’s bow, as it ensures a diversity of supply sources and

a highly differentiated position in this emerging market.

About GLOBAL BIOENERGIES

Global Bioenergies substitutes products of

fossil origin with products of natural origin. In their quest for

naturalness without compromising on performance, the cosmetics

players are the Company's first customers. By 2027, the Company

will be operating its innovative process in a large-scale plant. By

2030, the Company plans to become a leader in the huge emerging

market for sustainable aviation fuels, in order to fight against

global warming. Global Bioenergies is listed on Euronext Growth in

Paris (FR0011052257 - ALGBE). L'Oréal is its largest shareholder,

with a 13.5% stake.

About SkyNRG

SkyNRG is a global leader in Sustainable

Aviation Fuel (SAF). Since 2009, the company has been scaling up

SAF demand and production capacity for the industry to meet its

2050 net zero commitment. SkyNRG was the first in the world to

supply SAF on a commercial flight flown by co-founder and

shareholder KLM in 2011. To date, SkyNRG has supplied SAF to over

40 airlines across the world and is now developing dedicated

production facilities to support the shift from fossil jet fuel to

sustainable aviation fuel.

Contacts

|

GLOBAL BIOENERGIES+33 (0)1 64 98 20

50martin.stephan@global-bioenergies.com Follow our

news Receive information about Global Bioenergies

directly by subscribing to our news feed on

https://www.global-bioenergies.com/inscription-newsletter/ Follow

us on LinkedInGlobal Bioenergies |

|

NewCap – Investor

relationsLouis-Victor DelouvrierAurélie

Manavarereglobalbioenergies@newcap.eu+33 (0)1 44 71 94

94 NewCap – Media relations Nicolas

Merigeauglobalbioenergies@newcap.eu+33 (0)1 44 71 94 98 |

- Global Bioenergies_e-SAF process_EN_DEF

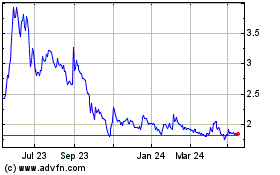

Global Bioenergies (EU:ALGBE)

Historical Stock Chart

From Nov 2024 to Dec 2024

Global Bioenergies (EU:ALGBE)

Historical Stock Chart

From Dec 2023 to Dec 2024