Exco Technologies Limited (TSX-XTC) today

announced results for its third quarter of fiscal 2024 ended June

30, 2024. In addition, Exco announced a quarterly dividend of

$0.105 per common share which will be paid on September 27, 2024 to

shareholders of record on September 13, 2024. The dividend is an

“eligible dividend” in accordance with the Income Tax Act of

Canada.

|

|

Three Months EndedJune 30 |

Nine Months EndedJune 30 |

|

(in $ thousands except per share amounts) |

|

|

|

|

|

|

2024 |

2023 |

2024 |

2023 |

| Sales |

$161,809 |

$164,551 |

$482,344 |

$459,151 |

| Net income for the period |

$8,176 |

$6,263 |

$21,884 |

$17,074 |

| Earnings per share:Basic and

Diluted – Reported |

$0.21 |

$0.16 |

$0.56 |

$0.44 |

|

EBITDA |

$22,257 |

$18,567 |

$61,541 |

$51,589 |

| |

|

|

|

|

“I am delighted to report that Exco achieved

very strong results again this quarter, chalking up our seventh

straight quarter of year over year increases in both EBITDA and

EPS”, said Darren Kirk, Exco’s President and CEO. “We expect to

achieve continued gains in the quarters ahead as we focus on

realizing the benefits of our strategic initiatives and further

strengthening our returns on capital. It is truly exciting to see

the pace of innovation happening across Exco as we leverage

advanced engineering, A.I. and machine learning to stay ahead of

global competition and significantly enhance our productivity and

efficiency. I want to extend my gratitude to all of my Exco

teammates for their hard work, dedication and working safely to

achieve these results and continuously innovating to further

improve Exco’s competitive position.”

Consolidated sales for the third quarter ended

June 30, 2024 were $161.8 million compared to $164.6 million in the

same quarter last year – a decrease of $2.8 million, or 2%. The

impact of foreign exchange rate changes increased sales $1.9

million in the quarter.

The Automotive Solutions segment reported sales

of $82.9 million in the third quarter – a decrease of $3.3 million

from the prior year quarter. Foreign exchange rate changes

increased segment sales in the quarter by $1.1 million. The modest

sales decrease was driven by customer driven delays in certain

program launches, unfavorable vehicle mix and slightly lower

blended vehicle production volumes in North America and Europe

compared to the prior year quarter. Looking forward, industry

growth may be tempered near term by traditional summer shut-downs

at OEM production facilities, elevated interest rates tempering

vehicle sales, relatively high vehicle average transaction prices,

rising dealer inventory levels, and softening global economic

conditions. Notwithstanding these expected impacts, vehicle sales

remain encouraging, dealer inventory levels remain below

pre-COVID-19 levels, the vehicle fleet continues to age, and OEM

incentives are rising. Exco’s sales volumes will nonetheless

benefit from awarded program launches that are expected to provide

ongoing growth in our content per vehicle. Quoting activity also

remains encouraging and we believe there is ample opportunity to

achieve our targeted growth objectives.

The Casting and Extrusion segment reported sales

of $78.9 million for the third quarter – an increase of $0.5

million from the same period last year. Foreign exchange rate

movements increased segment sales by $0.8 million in the quarter.

Demand for our extrusion tooling remains strong in both North

America and Europe. High interest rates negatively influenced the

building, construction and recreational vehicle extrusion

end-markets in prior quarters, but the construction end-market has

improved more recently while demand within the automotive market

has continued to gain momentum and sustainable energy end markets

remain strong. We remain focused on standardizing manufacturing

processes, enhancing engineering depth and centralizing critical

support functions across our various plants. These initiatives have

reduced lead times, enhanced product quality, expanded product

breadth and increased capacity, contributing to share gains in our

core markets. Management is also developing its Castool greenfield

locations in Morocco and Mexico which provide the opportunity to

gain market share in Europe and Latin America through better

proximity to local customers. In the die-cast tooling market, which

primarily serves the automotive industry, demand and order flow for

new moulds, associated consumable tooling and rebuild work remained

firm during the quarter, though slowed slightly from recent

activity. Industry vehicle production volumes remain healthy and

new, more efficient internal combustion engine/transmission

platforms are being launched, including an increase in hybrid

powertrain platforms. Battery electric platforms continue to be

developed, albeit at a slower pace compared to prior expectations.

Demand for associated giga-sized tooling has similarly pulled back,

although management continues to expect this market segment will

see significant growth in the coming years. We have reworked our

plants and equipment to accommodate this larger tooling and believe

we have the most advanced capabilities among our competitors

globally. We also continue to invest heavily to bolster our leading

market position in 3D printing, recently acquiring our sixth

additive printer. As well, our pace of innovation within this

market is clearly gaining momentum, yielding more and more

applications for our additively printed tooling components.

Consequently, demand for Exco’s 3D printed tooling continues to

grow strongly as customers focus on greater efficiency in all large

mould size segments – ie for both giga and non-giga sized die-cast

machines. Sales in the quarter were also aided by price increases,

which were implemented to protect margins from higher input costs.

Quoting remains very active and our backlog for die-cast moulds

remains elevated relative to historical norms.

Consolidated net income for the third quarter

was $8.2 million or basic and diluted earnings of $0.21 per share

compared to $6.3 million or $0.16 per share in the same quarter

last year – an increase of net income of $1.9 million or 30%. The

consolidated effective income tax rate was 27% in the current

quarter compared to 26% in the prior year quarter. The income tax

rate in the quarter was impacted by non-deductible losses,

geographic distribution, and foreign rate differentials.

The Automotive Solutions segment reported Pretax

Profit of $8.1 million in the third quarter, a decrease of $0.8

million from the prior year quarter. Variances in period

profitability were due to slightly lower sales, product mix shifts,

higher raw material pricing, rising labour costs in all

jurisdictions and foreign exchange movements. Labour costs in

Mexico have been particularly challenging in recent years and are

seeing added pressure in fiscal 2024 given the significant rise in

wages. Vehicle production volumes however remain relatively stable,

which has led to improvements in labour scheduling and reduced

expedited shipping costs. As well, pricing action and efficiency

initiatives continued to temper inflationary pressures. Although

production volumes have largely stabilized from a macroeconomic and

global perspective from recent years, volumes in this segment’s

fourth quarter are expected to follow typical seasonality trends

due to OEM summer shutdowns. Apart from these specific impacts,

management is cautiously optimistic that its overall cost structure

should improve margins in coming quarters. Pricing discipline

remains a focus and actions are being taken on current programs

where possible, though there is typically a lag of a few quarters

before the impact is realized. As well, new program awards are

priced to reflect management’s expectations for higher future

costs.

The Casting and Extrusion segment reported $7.1

million of Pretax Profit in the third quarter – an increase of $3.1

million or 77% from the same quarter last year and $1.6 million

from the second quarter fiscal 2024. The Pretax Profit improvement

is due to higher sales volumes within the extrusion end markets,

program pricing improvements, favorable product mix, and efficiency

initiatives across the segment, including the ongoing use of lean

manufacturing and automation to improve productivity through

standardization and waste elimination. As well, volumes at

Castool’s heat treatment operation continue to increase providing

savings and improved production quality while efficiency

initiatives at Halex are being realized. Offsetting these cost

improvements were ongoing start-up losses at Castool’s greenfield

operations and an increase in segment depreciation ($0.7 million

for the quarter) associated with recent capital expenditures.

Management remains focused on reducing its overall cost structure

and improving manufacturing efficiencies and expects such

activities together with its sales efforts should lead to improved

segment profitability over time.

Corporate segment expenses were $1.9 million in

the third quarter compared to $2.6 million in the prior year

quarter. The improvement relates to current quarter foreign

exchange gains partially offset by higher selling and travel

costs.

Consolidated EBITDA for the third quarter

totaled $22.3 million compared to $18.6 million in the same quarter

last year – an increase of $3.7 million or 20%. Year-to-date,

consolidated EBITDA totaled $61.5 million compared to $51.6 million

last year – an increase of $9.9 million or 19%. For the quarter,

EBITDA as a percentage of sales increased to 13.8% in the current

period compared to 11.3% the prior year driven by an improvement in

Casting & Extrusion segment margins (17.8% compared to 13.1%)

and the Automotive Solutions segment decreased slightly (12.1%

compared to 12.6%).

Exco generated cash from operating activities of

$22.7 million and Free Cash Flow of $15.9 million in the quarter

compared to $23.7 million and $16.9 million respectfully in the

prior year quarter. Maintenance Fixed Asset Additions were $4.7

million and interest was $2.1 million in the third quarter. During

the quarter the Company invested $3.2 million in growth capital

expenditures, paid $4.1 million in dividends, and used $1.0 million

for share buybacks. Exco ended the quarter with $20.3 million in

cash, $107.4 million in bank and long-term debt and $44.0 million

available in its credit facility, continuing its practice of

maintaining a strong balance sheet and liquidity position.

Outlook

By fiscal 2026, Exco is targeting to produce

approximately $750 million annual revenue, $120 million annual

EBITDA and annual EPS of roughly $1.50. Exco has made significant

progress towards achieving these targets since they were announced

and continues to believe its targets remain obtainable. These

targets are expected to be achieved through returns on greenfield

and strategic initiatives, the launch of new programs, general

market growth, and also market share gains consistent with the

Company’s operating history.

Despite current macro-economic challenges,

including slightly elevated unemployment, high interest rates, and

the potential for a recession, the overall outlook is favorable

across Exco’s segments into the medium term. Consumer demand for

automotive vehicles remains stable in most markets.

Dealer inventory levels have been increasing, while average

transaction prices for both new and used vehicles are near record

highs and the average age of the broader fleet has continued to

increase. This bodes well for strong levels of future vehicle

production and the sales opportunity of Exco’s various automotive

components and accessories. In addition, OEM’s are increasingly

looking to the sale of higher margin accessory products as a means

to enhance their own levels of profitability. Exco’s Automotive

Solutions segment derives a significant amount of activity from

such products and is a leader in the prototyping, development and

marketing of the same. Moreover, the movement towards an

electrified and hybrid fleet for both passenger and commercial

vehicles is enticing new market entrants into the automotive market

while causing traditional OEM incumbents to further differentiate

their product offerings, all of which is driving above average

opportunities for Exco.

With respect to Exco’s Casting and Extrusion

segment, the intensifying global focus on environmental

sustainability has created significant growth drivers that are

expected to persist through at least the next decade. Automotive

OEMs are utilizing light-weight metals such as aluminum to reduce

vehicle weight and reduce carbon dioxide emissions. This trend is

evident regardless of powertrain design - whether internal

combustion engines, electric vehicles or hybrids. As well, a

renewed focus on the efficiency of OEMs in their own manufacturing

process is creating higher demand for advanced tooling that can

enhance their profitability and sustainability goals. Certain OEM

manufacturers have begun utilizing much larger die cast machines

(“giga-presses”) to cast entire vehicle sub-frames using

aluminum-based alloy rather than stamping, welding, and assembling

separate pieces of ferrous metal. Exco is in discussions with

several traditional OEMs and their tier providers who appear likely

to follow this trend. Accordingly, Exco has positioned its

operations to capitalize on these changes. Beyond the automotive

industry, Exco’s extrusion tooling supports diverse industrial end

markets which are also seeing increased demand for aluminum driven

by environmental trends, including energy efficient buildings,

solar panels, etc.

On the cost side, inflationary pressures have

intensified post COVID while prompt availability of various input

materials, components and labour has become more challenging. The

intensity of these dynamics have generally moderated in recent

quarters with the exception of labour costs in Mexico, which

continue to see significant increases. We are offsetting these

dynamics through various efficiency initiatives and taking pricing

action where possible although there is typically several quarters

of lag before the counter measures yield results.

The Russian invasion of Ukraine and the

Israeli/Palestine conflict have added additional uncertainty to the

global economy. And while Exco has essentially no direct exposure

to these countries, Ukraine does feed into the European automotive

market and Europe has traditionally depended on Russia for its

energy needs. Similarly, the conflict in the Middle East creates

the potential for a renewed rise in the price of oil and other

commodities as well as logistics costs and could weigh on consumer

sentiment.

Non-IFRS Measures: In this News

Release, reference may be made to EBITDA, EBITDA Margin, Pretax

Profit, Free Cash Flow and Maintenance Fixed Asset Additions which

are not defined measures of financial performance under

International Financial Reporting Standards (“IFRS”). A

reconciliation to these non-GAAP measures is provided within this

MD&A. Exco calculates EBITDA as earnings before interest,

taxes, depreciation and amortization and EBITDA Margin as EBITDA

divided by sales. Exco calculates Pretax Profit as segmented

earnings before other income/expense, interest and taxes.

Free Cash Flow is calculated as cash provided by operating

activities less interest paid and Maintenance Fixed Asset

Additions. Maintenance Fixed Asset Additions represent management’s

estimate of the investment in fixed assets that is required for the

Company to continue operating at current capacity levels. Given the

Company’s elevated planned capital spending on fixed assets for

growth initiatives (including additional Greenfield locations,

energy efficient heat treatment equipment and increased capacity)

in recent years, the Company has modified its calculation of Free

Cash Flow to include Maintenance Fixed Asset Additions and not

total fixed asset purchases. This change is meant to enable

investors to better gauge the amount of generated cash flow that is

available for these investments as well as acquisitions and/or

returns to shareholders in the form of dividends or share buyback

programs. EBITDA, EBITDA Margin, Pretax Profit and Free Cash Flow

are used by management, from time to time, to facilitate

period-to-period operating comparisons and we believe some

investors and analysts use these measures as well when evaluating

Exco’s financial performance. These measures, as calculated by

Exco, do not have any standardized meaning prescribed by IFRS and

are not necessarily comparable to similar measures presented by

other issuers.

Quarterly Conference Call –

August 1, 2024 at 10:00 a.m. (Toronto time):

To access the listen only live audio webcast,

please log on to www.excocorp.com, or

https://edge.media-server.com/mmc/p/pq7nf726 a few minutes before

the event. Those interested in participating in the

question-and-answer conference call may register at

https://register.vevent.com/register/BI4875917e092447068fa522053dc93804

to receive the dial-in numbers and unique PIN to access the call.

It is recommended that you join 10 minutes prior to the event start

(although you may register and dial in at any time during the

call).

For those unable to participate on August 1, 2024, an archived

version will be available on the Exco website until August 17,

2024.

|

Source: |

Exco

Technologies Limited (TSX-XTC) |

| Contact: |

Darren Kirk, President and CEO |

| Telephone: |

(905) 477-3065 Ext. 7233 |

| Website: |

https://www.excocorp.com |

| |

|

About Exco Technologies Limited:

Exco Technologies Limited is a global supplier

of innovative technologies servicing the die-cast, extrusion and

automotive industries. Through our 21 strategic locations in

9 countries, we employ approximately 5,000 people and service a

diverse and broad customer base.

Notice To Reader: Forward Looking Statements

This press release contains forward-looking

information and forward-looking statements within the meaning of

applicable securities laws. We may use words such as "anticipate",

"may", "will", "should", "expect", "believe", "estimate", “5-year

target” and similar expressions to identify forward-looking

information and statements especially with respect to growth,

outlook and financial performance of the Company's business units,

contribution of our start-up business units, contribution of

awarded programs yet to be launched, margin performance, financial

performance of acquisitions, liquidity, operating efficiencies,

improvements in, expansion of and/or guidance or outlook as to

future revenue, sales, production sales, margin, earnings, earnings

per share, including the revised outlook for 2026, are

forward-looking statements. These forward-looking statements

include known and unknown risks, uncertainties, assumptions and

other factors which may cause actual results or achievements to be

materially different from those expressed or implied. These

forward-looking statements are based on our plans, intentions or

expectations which are based on, among other things, the current

improving global economic recovery from the COVID-19 pandemic and

containment of any future or similar outbreak of epidemic,

pandemic, or contagious diseases that may emerge in the human

population, which may have a material effect on how we and our

customers operate our businesses and the duration and extent to

which this will impact our future operating results, the impact of

the Russian invasion of Ukraine on the global financial, energy and

automotive markets, including increased supply chain risks,

assumptions about the demand for and number of automobiles produced

in North America and Europe, production mix between passenger cars

and trucks, the number of extrusion dies required in North America

and South America, the rate of economic growth in North America,

Europe and emerging market countries, investment by OEMs in

drivetrain architecture and other initiatives intended to reduce

fuel consumption and/or the weight of automobiles in response to

rising climate risks, raw material prices, supply disruptions,

economic conditions, inflation, currency fluctuations, trade

restrictions, energy rationing in Europe, our ability to integrate

acquisitions, our ability to continue increasing market share, or

launch of new programs and the rate at which our current and future

greenfield operations in Mexico and Morocco achieve sustained

profitability. Readers are cautioned not to place undue reliance on

forward-looking statements throughout this document and are also

cautioned that the foregoing list of important factors is not

exhaustive. The Company will update its disclosure upon publication

of each fiscal quarter's financial results and otherwise disclaims

any obligations to update publicly or otherwise revise any such

factors or any of the forward-looking information or statements

contained herein to reflect subsequent information, events or

developments, changes in risk factors or otherwise. For a more

extensive discussion of Exco's risks and uncertainties see the

'Risks and Uncertainties' section in our latest Annual Report,

Annual Information Form ("AIF") and other reports and securities

filings made by the Company. This information is available

at www.sedarplus.ca or www.excocorp.com.

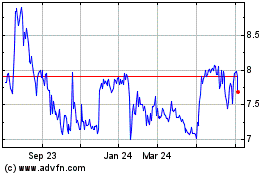

Exco Technologies (TSX:XTC)

Historical Stock Chart

From Dec 2024 to Jan 2025

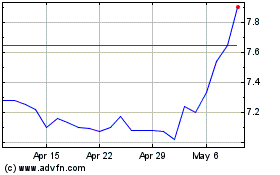

Exco Technologies (TSX:XTC)

Historical Stock Chart

From Jan 2024 to Jan 2025