IBC Engineered Materials Awarded Hard Tooling Contract from Lockheed Martin for F-35 Lightning II Application

19 February 2014 - 1:00AM

Marketwired

IBC Engineered Materials Awarded Hard Tooling Contract from

Lockheed Martin for F-35 Lightning II Application

Tooling for Beralcast(R) casting of F-35 Lightning II

Electro-Optical Targeting System Components

WILMINGTON, MASSACHUSETTS--(Marketwired - Feb 18, 2014) - IBC

Advanced Alloys Corp. (TSX-VENTURE:IB)(OTCQX:IAALF) ("IBC" or the

"Company") reports that its wholly owned US subsidiary, IBC

Engineered Materials Corp. ("IBC-EMC"), has been awarded an

investment casting hard tooling contract from Lockheed Martin in

support of its F-35 Lightning II Electro-Optical Targeting System

(EOTS).

Under the terms of the contract, IBC-EMC will be responsible for

the design, manufacture and implementation of hard tooling to be

used as a part of the final qualification process to establish

Beralcast® castings as an effective beryllium-aluminum alternative

for precision optical components for the F-35 Lightning II.

As previously disclosed, IBC-EMC is demonstrating the viability

of Beralcast® castings to improve lead times and affordability of

high performance aerospace components made from beryllium aluminum

alloys. IBC-EMC has completed several advanced prototype castings

and will now use the hard tooling to deliver a first article

casting for pre-production approval.

"IBC is pleased to have received a hard tool contract from

Lockheed Martin," said Ray White, President of IBC-EMC. "We are

committed to demonstrating the viability of Beralcast® castings

with a hard tool and to completing the final stages of our

materials and processing qualifications."

"It is an honor to be working with Lockheed Martin," said

Anthony Dutton, President and CEO of IBC. "Our Company is committed

to delivering advanced beryllium aluminum casting solutions, not

only for Lockheed Martin and the F-35 Lightning II but also for

other aerospace industry initiatives where modulus, weight and cost

are critical performance factors."

Beralcast® alloys can be used in virtually any high performance

application requiring complex, lightweight and high-stiffness parts

and can be substituted for aluminum, magnesium, titanium, metal

matrix composites as well as pure beryllium or powder metallurgy

beryllium-aluminum. Beralcast's® principal alloys are more than

three times stiffer than aluminum with 22% less weight and can be

precision-cast for simple and complex three-dimensional stability.

These high-modulus alloys are ideal for high performance industrial

and high tech components as well as for a wide range of aerospace

applications.

About IBC Advanced Alloys Corp.

IBC is an integrated manufacturer and distributor of rare metals

(beryllium) based alloys and related products serving a variety of

industries including nuclear energy, automotive, telecommunications

and a range of industrial applications. IBC has 80 employees and is

headquartered in Vancouver, Canada with production facilities in

Indiana, Massachusetts, Pennsylvania and Missouri. IBC is creating

a dynamic global beryllium and advanced alloys company. IBC's

common shares are traded on the TSX Venture Exchange under the

symbol "IB" and the OTCQX under the symbol "IAALF".

This news release was prepared by management of IBC, which

takes full responsibility for its contents. The TSX Venture

Exchange has not reviewed and does not accept responsibility for

the adequacy of this news release. Neither TSX Venture Exchange nor

its Regulation Services Provider (as that term is defined in the

policies of the TSX Venture Exchange) accepts responsibility for

the adequacy or accuracy of this release.

This disclosure contains certain forward-looking statements

that involve substantial known and unknown risks and uncertainties,

certain of which are beyond the Company's control including: the

impact of general economic conditions in the areas in which the

Company operates, industry conditions, changes in laws and

regulations including the adoption of new environmental laws and

regulations and changes in how they are interpreted and enforced,

increased competition, the lack of availability of qualified

personnel or management, limited availability of raw materials,

fluctuations in commodity prices, foreign exchange or interest

rates, stock market volatility and obtaining required approvals of

regulatory authorities. In addition there are risks and

uncertainties associated with manufacturing activities therefore

the Company's future results, performance or achievements could

differ materially from those expressed in these forward-looking

statements. All statements included in this press release that

address activities, events or developments that the Company

expects, believes or anticipates will or may occur in the future

are forward-looking statements. These statements are based on

assumptions made by the Company based on its experience, perception

of historical trends, current conditions, expected future

developments and other factors it believes are appropriate in the

circumstances.

IBC Advanced Alloys Corp.Ian TootillDirector of Corporate

Communications(604) 685-6263 ext

110itootill@ibcadvancedalloys.comwww.ibcadvancedalloys.comThe

Howard Group Inc.Dave Burwell(403) 221-0915 or Toll Free:

1-888-221-0915info@howardgroupinc.com

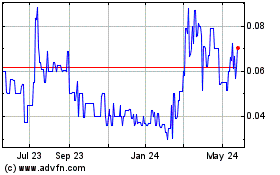

IBC Advanced Alloys (QB) (USOTC:IAALF)

Historical Stock Chart

From Dec 2024 to Jan 2025

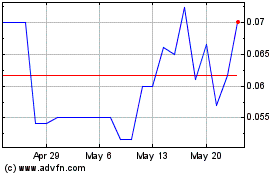

IBC Advanced Alloys (QB) (USOTC:IAALF)

Historical Stock Chart

From Jan 2024 to Jan 2025