ROCA-MAX Molybdenum Mine Achieves Commercial Production

17 April 2008 - 8:12AM

Marketwired

VANCOUVER, BRITISH COLUMBIA ("Roca" or "the Company") provides

the following update on operations and development activities at

the MAX Molybdenum Project near Revelstoke, British Columbia.

Highlights of this update include;

- Phase I Commercial Production was achieved on April 12,

2008;

- Startup operations produced approximately 410,000 lbs of

contained molybdenum in concentrate;

- Key Phase II expansion work to be completed in Summer 2008;

and,

- Phase I target production rates recently achieved.

Phase I Commercial Production Achieved

In February 2008, while operating at a prescribed lower

throughput rate for startup, the MAX mine and mill achieved

continuous daily throughput of approximately 80% of its Phase I

design rate of 500 tonnes per day. During the period, the mill also

achieved molybdenum recovery rates averaging 90%, exceeding the

design recovery of 87%.

Phase I ore grade material has recently been supplied from

underground stopes and delivered directly to the MAX mill and

concentrator. Based on a 10-day average grade of the ore supplied,

the diluted head grade from the mine exceeded 75% of the planned

mine-diluted grade of 1.7% MoS2. As a result of this recent

development, the Company is declaring that Phase I commercial

production was achieved on April 12, 2008.

Startup Operations

Startup operations at the MAX Molybdenum Mine have now overcome

minor challenges and disruptions to commissioning resulting from

crusher and mill equipment modifications, process optimization, and

reagent quality control. As planned, the initial operations made

use of lower-grade stockpiled development rock to facilitate the

startup production run. That material was significantly lower in

grade than the ore currently being processed. During the period,

the MAX operation delivered approximately 880,000 dry lbs of

concentrates containing an estimated 410,000 lbs of molybdenum,

with a gross metal value of $13.5 million based on average

molybdenum oxide prices during the period. Proceeds received from

concentrate sales during startup have been used for completion

costs and to fund ongoing Phase II expansion of the mine and

mill.

Phase II Expansion and Development

Previously, the Company announced the development of a second

adit to the mine working area. Adit #2 recently reached a

break-through location to workings in the mine, and final

completion of the connection is expected early in May 2008. Once

connected, the underground mine will be capable of achieving its

Phase II ventilation requirements. This will allow for concurrent

mine development and production to increase to 1,000 tonnes per day

for the first time in the history of the project.

The Company has also previously announced the acquisition of a

third primary ball mill. The installation of this mill will allow

for greater production flexibility and will provide for a nominal

capacity of at least 1,000 tonnes per day. The third mill has been

delivered to the site and power distribution systems and controls

have been prepared. Engineering of a new mill base is complete and

construction will commence shortly, with the new equipment to be

fully commissioned by the fall of 2008. A concentrate drying system

will also be installed during the month of May 2008, which will

assist in controlling moisture content in the concentrates

produced.

The Company plans to seek a graduated permit increase for the

operation of the Phase II mine enabling it to produce at the

as-built capacity in late 2008 and beyond. The application for this

increase in production rate will be submitted after environmental

and water quality data is collected and compiled this

spring/summer. The information will demonstrate that the mine is

working well within its compliance requirements and with minimal

impact to the environment.

Production Targets

Phase I target production rates are currently being realized and

are equivalent to approximately 300,000 lbs of contained molybdenum

in concentrate production per month. In the coming weeks, mill

throughput rate is expected to increase as all process operations

are raised to Phase I capacity.

Completion of the Phase II expansion work, as described above,

will provide opportunities for the mine and the mill to operate at

nominal rates of 1,000 tonnes per day. At those throughput rates,

and estimated tonnes and grades available from the mine schedule,

the Phase II production target for the remainder of calendar 2008

is estimated to be approximately 600,000 lbs of contained

molybdenum per month.

Accounting and Financial Reporting

Proceeds from sales of molybdenite concentrates from the date of

commercial production forward will be recorded as revenues and

associated costs treated as operating expenses which will first be

reflected in the Company's financial statements dated May 31, 2008

to be reported in July 2008. All costs associated with Phase I

production, have been capitalized to date, with any startup

concentrate proceeds recorded as a reduction to capital costs in

accordance with Canadian GAAP. Net pre-production costs will be

amortized on a unit of production basis over the Company's Phase I

mine plan.

The permitted Phase I mine plan for MAX will focus on the

deposit's high-grade zone containing 280,000 measured and indicated

tonnes grading 1.95% MoS2 (refer to T.N. Macauley's 43-101

compliant technical report dated September 2004 available via

SEDAR). Molybdenum oxide currently trades in the US$33-34/lb.

range.

ROCA MINES INC.

Scott E. Broughton, P.Eng. - President & CEO

The TSX Venture Exchange does not accept responsibility for the

adequacy or accuracy of this release.

Contacts: Roca Mines Inc. Doug Fosbrooke Investor Relations

(604) 684-2900 (604) 684-2902 (FAX) Email: info@rocamines.com

Website: www.rocamines.com

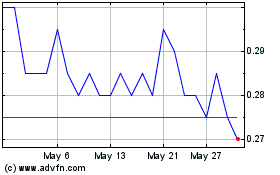

ROK Resources (TSXV:ROK)

Historical Stock Chart

From May 2024 to Jun 2024

ROK Resources (TSXV:ROK)

Historical Stock Chart

From Jun 2023 to Jun 2024