Following a strategic review of the Company’s software investment

strategy, 3D Systems (NYSE:DDD) today announced that it has signed

a definitive agreement to sell its Geomagic software

portfolio to the Manufacturing Intelligence Division of Hexagon, a

global leader in digital reality solutions, combining sensor,

software, and autonomous technologies, for $123 million. The

transaction is expected to close in the first half of 2025,

following the completion of customary regulatory reviews. The

Geomagic product portfolio is a powerful, proven integrated

software tool kit that includes Design X, Control X, Freeform,

Wrap, and Geomagic for SolidWorks. The Geomagic portfolio has built

a strong user base in, among other things, the market for creating

digital models from physical objects that can then be used to

manufacture the finished component. This process, commonly known as

‘reverse engineering,’ automates the processing of scan data

captured with a 3D scanner to create accurate CAD models. Certain

Geomagic products can also be used to design from scratch or modify

existing models and to accurately measure and inspect parts for

quality control purposes when finished. As a leader in scanning

technologies, Hexagon is ideally positioned to harness the power of

the Geomagic portfolio to offer a more complete scan-to-CAD

workflow, to bridge the physical and digital worlds.

Following the divestiture, 3D Systems will focus on its software

platforms that are core to customer adoption and application of its

3D printing technologies. These specifically include 3D Sprint,

3DXpert, and Oqton Industrial Manufacturing OS, each of which bring

unique value to customers targeting large-scale, production

applications. By concentrating development resources on these

platforms, 3D Systems believes it can accelerate its strategic

software development efforts and augment its product offerings to

empower customers to unlock the full potential of AM. This focus is

particularly important in order to increasingly leverage the

capabilities of AI and machine learning, as these powerful new

tools become more accessible to companies targeting,

high-reliability production environments and other critical

industrial settings. By focusing on these high-ROI,

mission-critical software offerings, the Company will better enable

the widespread adoption of additive manufacturing

significantly enhancing customer and shareholder value.

3DXpert and 3D Sprint are core to the company’s metal and

polymer additive manufacturing solutions respectively. 3DXpert is

renowned as a production-grade additive manufacturing software

solution that combines design for additive manufacturing (DfAM),

build preparation simulation and inspection in a single

environment. This enables shorter design-to-manufacture lead times,

optimized design structure, and reduced manufacturing costs. The

solution automates repetitive tasks and inspection through the

power of AI and machine learning to drive efficiency,

repeatability, and quality. 3D Sprint is exclusive software from 3D

Systems for preparing and optimizing CAD and polygon data and

managing the additive manufacturing process for its polymer 3D

printing technologies. The Company’s software engineers developed

this solution to support file preparation to production in the same

software environment with an easy-to-use interface to maximize

efficiency and avoid costly errors, saving customers both time and

money. Continued innovation alongside experts within 3D Systems’

Application Innovation Group (AIG) and print process team has

enabled a variety of segment-specific workflows to address

challenging applications. By focusing additional investment in

3DXpert and 3D Sprint, the Company will be able to place greater

emphasis on its R&D efforts to deliver enhanced capabilities

that will enable its customers to propel their innovation and

address a broader range of applications.

Integral to 3D Systems’ software strategy is the Company’s Oqton

Industrial Manufacturing OS that helps customers move from

prototyping to a repeatable and high-quality production additive

manufacturing process. Through the power of AI, Manufacturing OS is

intended to manage, optimize, automate, and prepare actions and

data to increase throughput, scale production, and maximize

operational efficiency. In early 2023, 3D Systems and Baker Hughes

began a formal collaboration on this solution. The goal of this

effort is to develop an industrial digital ecosystem that increases

efficiency and facilitates regulatory compliance to transform how

manufacturers bring their products to market in highly regulated

industries such as energy, aerospace, and healthcare.

“The additive manufacturing (AM) industry is rapidly evolving,

and we believe there are significant opportunities to drive

innovation that is critical to the wide-spread adoption of 3D

printing in production environments,” said Dr. Jeffrey Graves,

president & CEO, 3D Systems. “While advanced printing hardware

and engineering materials are essential to the new applications

that are of most interest to our customers, software is equally

important to the mass adoption of the technology. As the company

that commercialized the first 3D printing technology nearly four

decades ago and has the most extensive experience in mass

production of custom components, 3D Systems is well-positioned to

be a leader in moving AM from the lab to the factory floor. The

changes we’re announcing today will sharpen our focus on those

software platforms that are most critical to our customers’ success

in this new-use environment. By streamlining our software

operations, focusing exclusively on our core platforms, and

leveraging the exceptional capabilities that AI is now making

available to us, we will be better positioned to support our

customers' most critical requirements as they move 3D printing into

high-volume production environments.”

Dr. Graves concluded, “For those thousands of loyal Geomagic

customers who have been essential to our growth, we believe that

Hexagon is an ideal strategic owner for these assets and that the

future will be bright under their stewardship. For 3D Systems’

stakeholders, this transaction leaves the Company very

well-positioned for the future, with the broadest technology base

in the industry, the scale needed to support our customers in

production environments, and a fortified balance sheet to continue

driving our industry leading innovation.”

Forward-Looking StatementsCertain statements

made in this release that are not statements of historical or

current facts are forward-looking statements within the meaning of

the Private Securities Litigation Reform Act of 1995.

Forward-looking statements involve known and unknown risks,

uncertainties and other factors that may cause the actual results,

performance or achievements of the company to be materially

different from historical results or from any future results or

projections expressed or implied by such forward-looking

statements. In many cases, forward-looking statements can be

identified by terms such as "believes," "belief," "expects," "may,"

"will," "estimates," "intends," "anticipates" or "plans" or the

negative of these terms or other comparable terminology.

Forward-looking statements are based upon management’s beliefs,

assumptions, and current expectations and may include comments as

to the company’s beliefs and expectations as to future events and

trends affecting its business and are necessarily subject to

uncertainties, many of which are outside the control of the

company. The factors described under the headings "Forward-Looking

Statements" and "Risk Factors" in the company’s periodic filings

with the Securities and Exchange Commission, as well as other

factors, could cause actual results to differ materially from those

reflected or predicted in forward-looking statements. Although

management believes that the expectations reflected in the

forward-looking statements are reasonable, forward-looking

statements are not, and should not be relied upon as a guarantee of

future performance or results, nor will they necessarily prove to

be accurate indications of the times at which such performance or

results will be achieved. The forward-looking statements included

are made only as of the date of the statement. 3D Systems

undertakes no obligation to update or revise any forward-looking

statements made by management or on its behalf, whether as a result

of future developments, subsequent events or circumstances or

otherwise, except as required by law.

About 3D Systems More than 35 years ago, 3D

Systems brought the innovation of 3D printing to the manufacturing

industry. Today, as the leading additive manufacturing solutions

partner, we bring innovation, performance, and reliability to every

interaction - empowering our customers to create products and

business models never before possible. Thanks to our unique

offering of hardware, software, materials, and services, each

application-specific solution is powered by the expertise of our

application engineers who collaborate with customers to transform

how they deliver their products and services. 3D Systems’ solutions

address a variety of advanced applications in healthcare and

industrial markets such as medical and dental, aerospace &

defense, automotive, and durable goods. More information on the

company is available at www.3dsystems.com.

Investor Contact:

investor.relations@3dsystems.comMedia

Contact: press@3dsystems.com

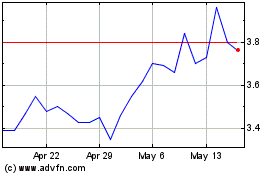

3D Systems (NYSE:DDD)

Historical Stock Chart

From Nov 2024 to Dec 2024

3D Systems (NYSE:DDD)

Historical Stock Chart

From Dec 2023 to Dec 2024