Henkel’s Expanded Gasketing Technology Enhances Performance and Reliability

15 August 2012 - 1:09PM

Business Wire

Henkel has expanded its gasketing technology portfolio with

new materials and processes designed to replace rubber gaskets in

demanding automotive applications. With its latest development –

the Loctite® 5883™ polyacrylate gaskets combined with

the new XIP gasketing process. Henkel provides its customers with a

unique sealing solution – a solution that allows them to dispense

high-performance compression gaskets within seconds, directly onto

automotive parts. This new process eliminates the need for solid

rubber press-in-place (PIP) gaskets and enables automotive OEMs and

tiered suppliers to enhance the performance and reliability of

their products while achieving productivity goals and reducing

overall costs.

Henkel's expanded gasketing technology

enhances performance and reliability (Photo: Business Wire)

The automotive industry is constantly shifting with evolving

performance and higher efficiency standards, driven by emerging

end-user requirements and stricter environmental regulations. This

pattern translates into new product design challenges, which the

automotive designers have to seek solutions for.

The use of light weight materials such as plastic materials has

been the common response from the industry to achieve fuel

efficiency and sustainability goals. Engines, Heating, Ventilation

and Air-Conditioning (HVAC) modules and electronics components

integrate an increasing number of plastic parts such as covers or

header tanks, which have to be sealed to the core component unit.

The most commonly used plastic-to-substrate sealing method is the

press-in-place (PIP) process, whereby the solid rubber gasket or

o-ring is manually applied onto the parts. With this process comes

a risk of displacement of the gasket during compression, leading to

rework or leakages.

Milestone in the automotive industry

With the introduction of the XIP gasket technology, Henkel

allows the fast, precise and series production-ready dispensing of

a liquid gasket directly onto automotive parts, replacing the PIP

method. The dispensed liquid material is cured by ultraviolet light

within seconds. The output is a perfectly uniform solid compression

gasket, with a constant height and perfect start and stop points.

These features are enabled by the volumetric dispensing system

offered by the XIP equipment. This reduces the risk of rework and

leakages, while improving the productivity and reducing the overall

cost by automating the gasketing process and eliminating the

inventory as well as the complexity of the PIP solid gaskets.

The new Loctite® 5883™ coupled with the new high-precision XIPG

gasketing process marks a milestone in chemical and process

development in the automotive industry, delivering benefits for

fast and efficient manufacturing, fuel efficiency and

sustainability.

To learn more about Loctite New Performance Gasketing, please

visit the Henkel website at: www.henkel.asia/autogasket.

Photo material is available at

http://www.henkel.com/press.

Henkel operates worldwide with leading brands and technologies

in three business areas: Laundry & Home Care,

Cosmetics/Toiletries and Adhesive Technologies. Founded in 1876,

Henkel holds globally leading market positions both in the consumer

and industrial businesses with well-known brands such as Persil,

Schwarzkopf and Loctite. Henkel employs about 47,000 people and

reported sales of 15,605 million euros and adjusted operating

profit of 2,029 million euros in fiscal 2011. Henkel’s preferred

shares are listed in the German stock index DAX and the company

ranks among the Fortune Global 500.

Photos/Multimedia Gallery Available:

http://www.businesswire.com/cgi-bin/mmg.cgi?eid=50373478&lang=en

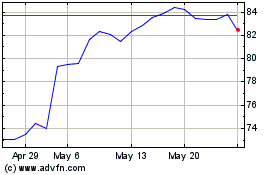

Henkel AG & Co KGAA (TG:HEN3)

Historical Stock Chart

From Jan 2025 to Feb 2025

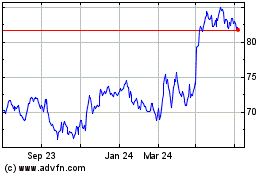

Henkel AG & Co KGAA (TG:HEN3)

Historical Stock Chart

From Feb 2024 to Feb 2025