TIDM1SN

RNS Number : 3792M

First Tin PLC

14 September 2023

14 September 2023

First Tin Plc

("First Tin" or "the Company")

Mineral Resource Estimate Upgrade at Taronga Tin Project

First Tin PLC ("First Tin"), a tin development company with

advanced, low capex projects in Germany and Australia, is pleased

to announce an updated Mineral Resource Estimate ("MRE") for its

100% owned Taronga Tin Project in Australia, completed by

independent geological consultants H&S Consultants Pty Ltd

("H&SC"). The MRE has been prepared in accordance with the 2012

JORC Code & Guidelines.

The updated MRE is reported using a 0.05% tin ("Sn") cut-off to

a maximum depth of 300m below surface (650mRL):

Category Tonnage (Million) Grade (% Tin (Tonnes)

Sn)

Measured 33.0 0.13 44,200

------------------ --------- -------------

Indicated 38.9 0.11 42,000

------------------ --------- -------------

Sub-Total

(M&I) 71.9 0.12 86,200

------------------ --------- -------------

Inferred 61.1 0.09 61,100

------------------ --------- -------------

TOTAL 133.0 0.10 138,300

------------------ --------- -------------

(minor rounding errors)

This is a substantial 240% increase in size on the previous MRE

announced by Aus Tin Mining Ltd in 2014 which was calculated using

a 0.10% Sn cut-off. The lower cut-off for the updated Mineral

Resource is based on revised economic considerations including

higher 3-year trailing tin prices, lower AUD:USD exchange rates and

preliminary estimates of mining, processing and G&A costs.

A direct comparison with the 2014 MRE using a 0.10% Sn cut-off

is:

2014 MRE H&SC 2023 MRE Percentage

Change

(%)

Tonnes Grade Tin (Tonnes) Tonnes Grade Tin (Tonnes)

(Million) (%Sn) (Million) (%Sn)

----------- ------- ------------- ----------- ------- -------------

Measured - - - 21.5 0.17 35,700 -

----------- ------- ------------- ----------- ------- ------------- -----------

Indicated 26.9 0.17 45,200 16.5 0.16 26,000 (42.5)

----------- ------- ------------- ----------- ------- ------------- -----------

Sub-Total 26.9 0.17 45,200 38.0 0.16 61,700 36.5

----------- ------- ------------- ----------- ------- ------------- -----------

Inferred 9.4 0.13 12,000 13.4 0.14 18,600 55

----------- ------- ------------- ----------- ------- ------------- -----------

TOTAL 36.3 0.16 57,200 51.7 0.16 80,300 40.4

----------- ------- ------------- ----------- ------- ------------- -----------

(minor rounding errors)

The comparison represents a 40% increase in total contained tin

metal based on the same cut-off. The difference is primarily due

to:

-- Exploration drilling by First Tin successfully extending the Mineral Resource to the southwest of the existing

estimate

-- A new geological interpretation

-- A reconfigured grade interpolation technique

A Measured Resource category has been included for the first

time. This is based on the successful hole twinning drill programme

conducted by First Tin which validated the Newmont drilling data

alongside a more in-depth study of the Newmont QAQC data which

confirmed the reliability of the historic drilling data.

A grade-tonnage table is included as Table 1 with a graphical

representation shown as Figure 1.

First Tin CEO Thomas Buenger said: "The 2023 MRE represents the

culmination of a highly successful drill campaign at Taronga, which

opened up new areas of mineralisation and validated previous data.

We are very pleased with the large increase in contained tin and

the addition of a Measured Resource category, which provides

further confidence in the MRE. The grade-tonnage curve shows that

the Mineral Resource Estimate is robust and that significant

tonnages of higher-grade material exist that will in turn reduce

risk due to changing tin prices."

The project is owned by First Tin's 100% owned Australian

subsidiary, Taronga Mines Pty Ltd ("TMPL").

Sn Cut

off % Mt Sn % Sn Kt

0.025 197.3 0.082 161.8

------ ------ ------

0.04 157.0 0.095 149.1

------ ------ ------

0.05 133.0 0.104 138.3

------ ------ ------

0.06 111.4 0.113 125.9

------ ------ ------

0.07 92.6 0.123 113.8

------ ------ ------

0.08 76.0 0.134 101.9

------ ------ ------

0.09 62.4 0.145 90.5

------ ------ ------

0.1 51.5 0.156 80.3

------ ------ ------

0.125 32.0 0.183 58.6

------ ------ ------

0.15 20.5 0.209 42.9

------ ------ ------

0.2 8.7 0.261 22.7

------ ------ ------

0.25 3.8 0.315 11.9

------ ------ ------

0.3 1.7 0.37 6.1

------ ------ ------

0.5 0.1 0.589 0.7

------ ------ ------

Table 1: Tin Grade-Tonnage Table for Taronga

Figure 2 shows an oblique view of the tin block grade

distribution for the Taronga Mineral Resources (figure in local

grid orientation). The black ellipse highlights the additional

resource discovered by First Tin.

Figure 3 demonstrates in an oblique view the distribution of

Resource Categories for the Taronga tin deposit (figures in local

grid orientation).

All Resource Categories

Measured & Indicated

Measured

Figure 3: Distribution of Mineralisation by Category,

Taronga

Enquiries:

First Tin Via SEC Newgate below

Thomas Buenger - Chief Executive

Officer

Arlington Group Asset Management

Limited (Financial Advisor

and Joint Broker)

Simon Catt 020 7389 5016

WH Ireland Limited (Joint

Broker)

Harry Ansell 020 7220 1670

SEC Newgate (Financial Communications)

Elisabeth Cowell / Molly FirstTin@secnewgate.co.uk

Gretton

Notes to Editors

First Tin is an ethical, reliable, and sustainable tin

production company led by a team of renowned tin specialists. The

Company is focused on becoming a tin supplier in conflict-free, low

political risk jurisdictions through the rapid development of high

value, low capex tin assets in Germany and Australia.

Tin is a critical metal, vital in any plan to decarbonise and

electrify the world, yet Europe has very little supply. Rising

demand, together with shortages, is expected to lead tin to

experience sustained deficit markets for the foreseeable future.

Its assets have been de-risked significantly, with extensive work

undertaken to date.

First Tin's goal is to use best-in-class environmental standards

to bring two tin mines into production in three years, providing

provenance of supply to support the current global clean energy and

technological revolutions.

JORC Code, 2012 Edition - Table 1 Taronga Tin Project (TMPL)

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

Criteria JORC Code explanation Commentary

Sampling

techniques * Nature and quality of sampling (eg cut channels, * Sampling consisted of two surface drilling phases:

random chips, or specific specialised industry Newmont 1979 to 1982 and Taronga Mines Pty Ltd (TMPL)

standard measurement tools appropriate to the 2022 to 2023.

minerals under investigation, such as down hole gamma

sondes, or handheld XRF instruments, etc). These

examples should not be taken as limiting the broad * Diamond drilling (DD) was used to obtain 1m samples

meaning of sampling. of NQ3/HQ3 core which was sawn in half

longitudinally. The half core was bagged and sent to

a commercial laboratory for sample prep and assay.

* Include reference to measures taken to ensure sample This is industry standard work.

representivity and the appropriate calibration of any

measurement tools or systems used.

* The Newmont open hole percussion (OHP) and JACRO

percussion drilling was used to obtain 1m samples. (a

* Aspects of the determination of mineralisation that JACRO percussion rig was used to sample shallow areas

are Material to the Public Report. with shallow angled drillholes).

* In cases where 'industry standard' work has been done * The TMPL Reverse Circulation (RC) drilling was used

this would be relatively simple (eg 'reverse to obtain 1m samples from a 4.5 inch diameter drill

circulation drilling was used to obtain 1 m samples hole. This is industry standard work.

from which 3 kg was pulverised to produce a 30 g

charge for fire assay'). In other cases more

explanation may be required, such as where there is * To ensure sample representivity all diamond drilling

coarse gold that has inherent sampling problems. was triple tube.

Unusual commodities or mineralisation types (eg

submarine nodules) may warrant disclosure of detailed

information. * To ensure sample representivity appropriate

compressors were used for the OHP/JACRO/RC drilling

to lift all the sample and prevent water inflows.

* Mineralisation is characterised as sheeted quartz

veins with minor cassiterite, arsenopyrite and

chalcopyrite in hornfelsed metasediments. Veins are

often hairline fractures and there is no obviously

visible pervasive alteration associated with the

hornfelsing. No discrete boundaries to the

mineralisation are known to exist. All drilling

samples were analysed and hence no prior

determination of mineralisation was made.

* Laboratory sample prep involved industry standard

drying, weighing and crushing followed by splitting

(where sample size was too large) and pulverising.

For Newmont this was completed on site with analysis

at a commercial laboratory, whilst for TMPL the

sample prep and analysis was completed at a

commercial laboratory. The subsequent pulp sample was

analysed by an appropriate industry standard method

for the time.

============================================================

Drilling

techniques * Drill type (eg core, reverse circulation, open-hole * Details of drilling for the general area:

hammer, rotary air blast, auger, Bangka, sonic, etc)

and details (eg core diameter, triple or standard Company Type No of Holes Metres

tube, depth of diamond tails, face-sampling bit or Newmont DD 173 25,718.8

other type, whether core is oriented and if so, by ------- ------------ ---------

what method, etc). OHP 81 5,573.5

------------------ ------------ ---------

JACRO 97 3,771.0

------------------ ------------ ---------

Total 351 35,063.3

------------------ ------------ ---------

TMPL Type No of Holes Metres

------- ------------ ---------

DD 13 1,619.2

------------------ ------------ ---------

RC 46 4,714.0

------------------ ------------ ---------

Total 59 6,333.2

------------------ ------------ ---------

Combined Type No of Holes Metres

------- ------------ ---------

DD 186 27,338.0

------------------ ------------ ---------

OHP 81 5,573.5

------------------ ------------ ---------

RC 46 4,714.0

------------------ ------------ ---------

JACRO 97 3,771.0

------------------ ------------ ---------

Total 410 41,396.5

------------------ ------------ ---------

Newmont

* DD were collared HQ or with OHP, reducing to NQ

triple tube once solid ground was met. Triple tube

drilling was employed to maximise core recovery and

minimise the loss of cassiterite. Core was not

oriented.

* OHP drilling was originally undertaken using a high

pressure Schramm rig. Later percussion drilling,

including all drillholes in the PG 400 series, used a

high pressure T-3 rig with a 140mm tungsten bit. The

rig was equipped with a primary cyclone connected to

a manifold at the collar for sample recovery. A

secondary Donaldson filter was attached to the outlet

of the primary cyclone to collect minus 5 micrometre

dust.

* A modified JACRO percussion rig equipped with a

vacuum sample recovery system was used exclusively

for Newmont's shallow angle drilling.

TMPL

* Diamond drilling was undertaken using an HQ bit with

a soft matrix. Triple tube drill rods were used to

ensure good core recovery and avoid washing out of

cassiterite. Core was not oriented.

* Percussion drilling was undertaken using a face

sampling 4.5 inch "Black Diamond" hammer, 137mm PED

(polycarbonate diamond) bit and a 4.5 inch, 6m

stainless steel rod. A tight shroud (3mm gap) ensured

the holes remained as straight as possible. A 350psi,

900cfm compressor was used to keep holes dry and

ensure all heavy minerals such as cassiterite are

recovered.

Drill sample

recovery * Method of recording and assessing core and chip * All core intervals are measured and compared with the

sample recoveries and results assessed. drillers marks to determine actual recovery. Recovery

was generally 100% apart from isolated intervals with

poor ground conditions, generally either near surface

* Measures taken to maximise sample recovery and ensure or in fault zones. Average recovery for Newmont DD is

representative nature of the samples. 97.3% with average recovery for TMPL DD of 96.8%

* Whether a relationship exists between sample recovery * All RC and OHP samples were weighed at site. This

and grade and whether sample bias may have occurred gives a good idea as to recovery for the 1m intervals

due to preferential loss/gain of fine/coarse sampled as the density does not vary significantly.

material. Recovery for the OHP was estimated to be very good in

general. Semi quantitative analysis of the TMPL

weighed RC samples indicated an average recovery

>90%.

* No information on the JACRO holes' recovery was

available.

* All diamond drilling used triple tube rods to

maximise sample recovery.

* There is some speculation by TMPL that the drilling

and core cutting processes may have resulted in small

scale loss of tin through washout associated with the

vein margins and very small vughs in the tin-bearing

veins. Conclusive evidence for this is lacking.

* For the percussion drilling a high pressure and

volume compressor was used to ensure good sample

return and to keep holes dry. No significant water

was encountered meaning sample quality was good. The

hole was cleaned out with compressed air after every

rod change and no significant volume of material was

returned via this process.

* No relationship can be seen between recovery and tin

grade. No sample bias is noted.

* Previous work by Mining One suggested that there was

downhole smearing of tin grade associated with the

JACRO drilling based on geostatistical work, but a

review of the Newmont JACRO/DD twin hole drilling

indicated no bias; check modelling without the JACRO

drilling indicated no difference in global block

grades. Visual inspection might suggest possible

smearing but it is difficult to be certain. The JACRO

holes were included in the Mineral Resource estimate.

============================================================

Logging

* Whether core and chip samples have been geologically * All samples have been geologically logged to a level

and geotechnically logged to a level of detail to of detail to support appropriate mineral estimation,

support appropriate Mineral Resource estimation, mining, and metallurgical studies.

mining studies and metallurgical studies.

* The TMPL diamond holes have been geotechnically

* Whether logging is qualitative or quantitative in logged to a level of detail to support appropriate

nature. Core (or costean, channel, etc) photography. mineral estimation, mining, and metallurgical studies

* The total length and percentage of the relevant * All drill core logging is both qualitative and

intersections logged. quantitative in nature, with the TMPL logging

following a strict set of guidelines. The entire

length each hole has been logged.

* The Newmont drilling was completed as hardcopy

logsheets which were transcribed into a digital

format in 2013. All TMPL core was digitally logged

and has been photographed.

* All RC, OHP and JACRO logging is semi-quantitative in

nature, with the TMPL RC drilling following a strict

set of guidelines, with percentage estimates made.

Representative sub-samples were collected, sieved and

selectively panned to visually estimate heavy mineral

content. A sub-set of rock chips for each RC sample

are kept in chip-trays for reference and stored on

site.

Sub-sampling Newmont drilling sample prep

techniques * If core, whether cut or sawn and whether quarter, * NQ core was sawn in half longitudinally at 1m

and sample half or all core taken. intervals with one half dispatched to Analabs Pty

preparation Limited ("Analabs") in Perth, Australia for assay.

The half core selected for assay was crushed (size

* If non-core, whether riffled, tube sampled, rotary unknown) then ground to 500 microns from which a 100g

split, etc and whether sampled wet or dry. sample was split and pulverized to less than 75

microns. A lab duplicate of each tenth sample was

split and pulverised to check sample preparation and

* For all sample types, the nature, quality and assaying reliability. These were appropriate,

appropriateness of the sample preparation technique. industry standard, sampling and sample preparation

techniques for the time.

* Quality control procedures adopted for all

sub-sampling stages to maximise representivity of * All 1m percussion drill samples were prepared for

samples. assay on site using four stages of size reduction

comprising jaw crusher, rolls crusher, disc grinder

and ring grinder (pulveriser), with sample splitting

* Measures taken to ensure that the sampling is between stages in accord with Pierre Gy's

representative of the in situ material collected, "Particulate Sampling Procedures". The pulverised

including for instance results for field material was dispatched to Analabs in Perth for

duplicate/second-half sampling. assay.

* Whether sample sizes are appropriate to the grain * A duplicate of each tenth sample was split and

size of the material being sampled. pulverised to check sample preparation and assaying

reliability. These were appropriate, industry

standard, sampling and sample preparation techniques

at the time.

* Duplicate samples showed that a majority of duplicate

Sn assays deviated by less than 2.5% relative to

perfect correlation.

TMPL drilling sample prep

* HQ core was sawn in half longitudinally after fitting

together of core across drillers breaks and a

reference line marked on the core. A consistent side

of the core is taken for sampling with the samples

sent to the ALS laboratory in Brisbane, Australia.

* All RC cuttings were weighed then riffle split on

site to obtain between 3kg and 5kg of sample. All

samples are dry. The sub-sample is sent to the ALS

laboratory in Brisbane.

* Core and RC chip sample prep consists of crushing to

70% passing 6mm with splitting used if crushed sample

is over 3kg. The entire sample or sub-sample is then

pulverized in a mill to 85% finer than 75um.

* Prior to dispatch of samples, the following QAQC

samples are added:

o Field duplicates are added at the rate of

1 in 20 samples for RC. These are riffle split

from the original sample on site.

o For diamond drilling, the half core is split

into two quarter cores every 1 in 20 samples

and these are sent as field duplicates .

* Sample sizes are considered appropriate for the

material being sampled as the tin mineralisation

occurs as cassiterite (SnO(2) ) within sub-vertical

veins that are between 0.05mm and 0.5cm wide (rarely

to 5cm) and cassiterite crystals are smaller than the

vein width. Vein density varies from about 5/m to

greater than 20/m and hence several veins are sampled

in each metre. This compares favourably with the

sample size that is approximately 10,000 cm(3) for RC

and 3,200cm(3) for HQ core before sub-sampling.

* No independent sizing checks were completed. The ALS

Lab completed its own internal checks and reported

the results.

============================================================

Quality Newmont

of assay * The nature, quality and appropriateness of the * All Sn assays were performed by taking 10g samples

data and assaying and laboratory procedures used and whether from the 100g pulverised samples. The samples were

laboratory the technique is considered partial or total. analysed for Sn using pressed powder X-ray

tests fluorescence at Analabs. Pressed powder X-ray

fluorescence was the industry standard for Sn

* For geophysical tools, spectrometers, handheld XRF analysis at the time.

instruments, etc, the parameters used in determining

the analysis including instrument make and model,

reading times, calibrations factors applied and their * Comparison of Sn assays of samples from diamond drill

derivation, etc. and percussion holes was good and no bias between the

two sets of analyses is evident.

* Nature of quality control procedures adopted (eg

standards, blanks, duplicates, external laboratory * For every 30 samples, four standards were inserted on

checks) and whether acceptable levels of accuracy (ie rotation. In addition, every tenth sample was lab

lack of bias) and precision have been established. duplicate assayed.

* Selected samples were check assayed at other

laboratories and using other assay methods, including

an XRF method developed by Cleveland Tin Limited in

Tasmania which was a significant Australian tin

producer at the time. The checks confirmed that

Analab's procedures were satisfactory and that sample

preparation and assay quality were consistently

maintained by Analabs.

TMPL

* All Sn assays were performed on a 0.1g sub-sample of

the pulverised and mixed material, which was taken

and fused with lithium borate. The fused bead is then

analysed by a mass spectrometer using method ME-MS85

which reports Sn, W, Ta and Nb. This returns a total

tin content, including tin as cassiterite. Over limit

assays of tin are re-analysed using method ME-XRF15b

which involves fusion with lithium metaborate with a

lithium tetraborate flux containing 20% NaNO(3) with

an XRF finish.

* Other elements are analysed by method ME-ICP61 using

a 0.25g sub-sample. This involves a 4 acid digest

with an ICP-AES finish. This is an industry standard

technique for a suite of 34 elements, including tin,

copper, arsenic, sulphur and silver. The tin assay is

only acid soluble tin and thus can be subtracted from

the fusion tin assays to obtain tin as cassiterite.

Acid soluble tin is generally associated with

stannite and in the lattice of silicates. The acid

soluble tin is generally insignificant in relation to

tin as cassiterite at Taronga.

* Prior to dispatch of samples, the following QAQC

samples were added:

o 3 Certified Reference Materials, representative

of the expected grades were inserted into the

sample suite at the rate of 1 in 40 samples.

o Coarse Blanks were inserted at the rate of

1 in 40 samples.

* If results for the CRMs indicated a >5% assay error,

the sample was compared with other CRMs in the same

batch. If other CRMs indicated similar errors the lab

was contacted to review.

* All QAQC data is within acceptable limits.

Verification Newmont

of sampling * The verification of significant intersections by * There is no information on any verification of

and assaying either independent or alternative company personnel. significant intersections by either independent or

alternative company personnel.

* The use of twinned holes.

* Geological interpretations were made using

cross-sections and level plans. Mining One accepted

* Documentation of primary data, data entry procedures, the Northern Zone 101 and the Southern Zones of

data verification, data storage (physical and Payback, Payback Extended, Hillside and Hillside

electronic) protocols. Extended were interpreted on cross-sections as

reported in a Pre-feasibility Study prepared by

Newmont Holdings Pty Ltd in 1982.

* Discuss any adjustment to assay data.

* A small number of twinned holes (10 pairs) were

completed by Newmont and comparison of length

weighted intercepts indicated no obvious bias.

* There is no information available on documentation of

primary data, data entry procedures, data

verification, data storage. It is assumed all data

was paper copies subsequently transcribed by

AusTinMining using a data entry bureau service.

* There are no reports of any adjustments made to the

assay data, although it appears that some transcribed

assay data was limited to 2 decimal places rendering

very low grade data as zeroes.

TMPL

* Simon Tear, a director of independent consultants H&S

Consultants Pty Ltd, has viewed and verified all core

from 6 DD holes.

* Twinning of previous Newmont drillholes has included:

o 11 TMPL DD twins of Newmont DD Holes

o 2 TMPL DD twins of Newmont OPH holes

o 5 TMPL RC twins of Newmont OPH holes

* Twin holes were selected to represent all zones of

mineralisation and the length of the known deposit.

* All results are within acceptable limits taking into

account any possible nugget effect resulting from

coarse cassiterite (noticed in three drill

intersections). Due to the small number of high grade

veins, top cutting of the high grade assays has a

negligible effect on the overall grade.

* All data is recorded on site in MSExcel spreadsheets

and this is later transferred to an MSAccess database

- the main data repository via cut and paste.

Detailed protocols for data recording, logging codes

etc are used. The assay data is received from the

laboratory (ALS) via csv and pdf files with attached

certificates. This may also be downloaded directly

from the ALS website by the senior project geologist.

The assay data is then merged using sample number.

Detailed protocols for data recording, logging codes

etc are used.

* Assays below lower detection limits were substituted

with half lower detection limit.

============================================================

Location Newmont

of data * Accuracy and quality of surveys used to locate drill * Drill hole collars were located by theodolite

points holes (collar and down-hole surveys), trenches, mine traverses by qualified surveyors.

workings and other locations used in Mineral Resource

estimation.

* A local grid parallel to the strike of the

mineralisation was used. Local grid north has a

* Specification of the grid system used. bearing of 055.103(O) true. A 3.5km baseline was

surveyed with surveyed cross-lines at 100m intervals.

* Quality and adequacy of topographic control.

* Holes were surveyed down-hole for azimuth and dip

using down-hole cameras with a range of downhole

depths from 15m to 50m. Given the generally

non-magnetic nature of the mineralisation and the

host rocks, this was a reasonable survey method.

* Topographic maps at 1:1000 scale were prepared by

Australian Aerial Mapping. The maps were related to

the local grid.

TMPL

* All hole collars are accurately surveyed post

drilling with a RTK GPS (+/-0.1m accuracy).

* All DD are surveyed downhole at 30m intervals using

Axis Champ Gyroscope.

* All RC holes are surveyed at 30m intervals using a

Trushot Digital survey tool.

* The grid system used is GDA94, zone 56.

* Topography is obtained via a LiDAR survey flown in

late 2022 and is to sub-10cm accuracy.

* All data was converted to local grid by H&SC for

resource estimation work.

* H&SC undertook field measurement of 20 drill collars

from both phases using a hand held GPS. Average

discrepancy was 0.5m in the easting and 0.5m in the

northing.

Data spacing

and * Data spacing for reporting of Exploration Results. * The Newmont drilling was nominally on a 50m by 50m

distribution pattern with 25m infill drilling in some areas.

* Whether the data spacing and distribution is

sufficient to establish the degree of geological and * The TMPL drilling completed in 2022/3 was nominally

grade continuity appropriate for the Mineral Resource at the same 50m by 50m spacing.

and Ore Reserve estimation procedure(s) and

classifications applied.

* Virtually all downhole sampling was 1m intervals from

surface.

* Whether sample compositing has been applied.

* Data spacing is sufficient to establish the

geological and grade continuity appropriate for the

Mineral Resource estimation and classification

procedures applied for this report.

* No sample compositing has been applied.

============================================================

Orientation

of data * Whether the orientation of sampling achieves unbiased * The drilling is oriented at 90deg to the strike of

in relation sampling of possible structures and the extent to the sheeted vein system.

to which this is known, considering the deposit type.

geological

structure * The vein system is sub-vertical and the drilling is

* If the relationship between the drilling orientation angled between -25deg and -60deg to be as close as

and the orientation of key mineralised structures is possible to cutting across the veins at 90deg. Due to

considered to have introduced a sampling bias, this difficulties drilling at very shallow angles,

should be assessed and reported if material. especially with RC, a default angle of -60deg was

adopted for the later TMPL drillholes.

* As drilling was designed to cut the main sheeted vein

system at as high an angle as possible, the potential

for any introduced sampling bias is considered minor.

Sample

security * The measures taken to ensure sample security. * Samples of Newmont drill core and percussion chips

were bagged and tagged and shipped to the assay

laboratory by independent third party transport. No

further information is available.

* A chain of custody was maintained for all TMPL

drilling.

* TMPL samples were placed in calico bags in groups of

seven which were then wrapped in opaque polyweave

bags, stacked on a palette and wrapped with pallet

wrap and tape.

* Samples sent to the lab via registered courier with

tracking capabilities.

* Samples arrive at the lab and were cross checked with

a separate despatch form (electronically sent to

ALS).

============================================================

Audits

or reviews * The results of any audits or reviews of sampling * An review of sampling procedures and protocols was

techniques and data. completed by Simon Tear of independent consultants

H&S Consultants Pty Ltd whilst drilling was in

progress, with some recommendations.

============= ============================================================ =============================================================================

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this

section.)

Criteria JORC Code explanation Commentary

Mineral

tenement * Type, reference name/number, location and ownership * The project is secured by two granted tenements:

and land including agreements or material issues with third EL8407 and ML 1774, both of which are currently in

tenure status parties such as joint ventures, partnerships, good standing. These are held 100% by TMPL.

overriding royalties, native title interests,

historical sites, wilderness or national park and

environmental settings. * No joint ventures or other encumbrances are known.

The underlying properties are freehold land owned

100% by TMPL apart from a block of Crown Land that

* The security of the tenure held at the time of covers part of the southern deposit area as defined

reporting along with any known impediments to by Newmont.

obtaining a licence to operate in the area.

* The Crown Land is the only land subject to Native

Title. No Native Title claims existed at the time the

tenements were granted.

* No national parks, historical sites or environmental

constraints are known. Recent surveys have identified

the "vulnerable" flora species Velvet Wattle. This is

currently being avoided as much as possible and is

not considered to be a major constraint moving

forward.

* The only royalty is the state of NSW royalty of 4% on

tin mined.

===============================================================

Exploration

done by * Acknowledgment and appraisal of exploration by other * Detailed exploration and feasibility studies were

other parties parties. undertaken by Newmont between 1979 and 1984. These

have been used where applicable.

* This work was undertaken to a high standard and all

data is considered to be usable.

Geology

* Deposit type, geological setting and style of * The tin deposit is a sheeted vein style +/-

mineralisation. copper-silver with horizontally and vertically

extensive veins of quartz-mica-cassiterite-sulphide

+/-fluorite-topaz occurring over a combined area of

up to 2,700m by 270m.

* The veins vary in thickness from less than 0.5mm to

100mm but are generally between 1mm and 10mm thick

and average about 20 veins per metre.

* The host rock is hornfels derived by contact

metamorphism of Permian aged metasediments by

Triassic-aged granites.

* The source of mineralising fluids is interpreted to

be an underlying intrusion of the Triassic Mole

Leucogranite, a reduced, highly fractionated, A to I

type granite. The metals of interest (Sn, Cu, Ag) are

interpreted to have been enriched in the late

magmatic fluid of this granite via enrichment of

incompatible elements during fractional

crystallisation. Breaching of the magma chamber

during brittle faulting in an ENE orientation, a

structural corridor, has tapped these enriched fluids

which have subsequently deposited the metals due to

changing temperature and pressure conditions and/or

mixing with meteoric fluids.

===============================================================

Drill hole * No Exploration Results are being reported.

Information * A summary of all information material to the

understanding of the exploration results including a

tabulation of the following information for all

Material drill holes:

o easting and northing of the drill hole collar

o elevation or RL (Reduced Level - elevation

above sea level in metres) of the drill hole

collar

o dip and azimuth of the hole

o down hole length and interception depth

o hole length.

* If the exclusion of this information is justified on

the basis that the information is not Material and

this exclusion does not detract from the

understanding of the report, the Competent Person

should clearly explain why this is the case.

Data * No Exploration Results are being reported.

aggregation * In reporting Exploration Results, weighting averaging

methods techniques, maximum and/or minimum grade truncations

(eg cutting of high grades) and cut-off grades are

usually Material and should be stated.

* Where aggregate intercepts incorporate short lengths

of high grade results and longer lengths of low grade

results, the procedure used for such aggregation

should be stated and some typical examples of such

aggregations should be shown in detail.

* The assumptions used for any reporting of metal

equivalent values should be clearly stated.

===============================================================

Relationship

between * These relationships are particularly important in the * As mineralisation is sub-vertical and while holes dip

mineralisation reporting of Exploration Results. at between -25deg and -60deg, actual true widths vary

widths and from 88% to 50% of interval widths.

intercept

lengths * If the geometry of the mineralisation with respect to

the drill hole angle is known, its nature should be * No Exploration Results are being reported.

reported.

* If it is not known and only the down hole lengths are

reported, there should be a clear statement to this

effect (eg 'down hole length, true width not known').

Diagrams * No Exploration Results are being reported.

* Appropriate maps and sections (with scales) and

tabulations of intercepts should be included for any

significant discovery being reported These should

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

===============================================================

Balanced * No Exploration Results are being reported.

reporting * Where comprehensive reporting of all Exploration

Results is not practicable, representative reporting

of both low and high grades and/or widths should be

practiced to avoid misleading reporting of

Exploration Results.

Other

substantive * Other exploration data, if meaningful and material, * A detailed feasibility study is currently in

exploration should be reported including (but not limited to): progress. Bulk samples have been collected for

data geological observations; geophysical survey results; metallurgical testwork and the testwork has shown

geochemical survey results; bulk samples - size and that a saleable concentrate can be produced at

method of treatment; metallurgical test results; bulk reasonable recovery using simple off the shelf

density, groundwater, geotechnical and rock gravity techniques.

characteristics; potential deleterious or

contaminating substances.

===============================================================

Further

work * The nature and scale of planned further work (eg * A definitive feasibility study is currently in

tests for lateral extensions or depth extensions or progress. No further drilling is planned as part of

large-scale step-out drilling). that process.

* Diagrams clearly highlighting the areas of possible

extensions, including the main geological

interpretations and future drilling areas, provided

this information is not commercially sensitive.

=============== =============================================================== ============================================================

Section 3 Estimation and Reporting of Mineral Resources

(Criteria listed in section 1, and where relevant in section 2,

also apply to this section.)

Criteria JORC Code explanation Commentary

Database

integrity * Measures taken to ensure that data has not been * The Newmont drilling data was supplied by TMPL as an

corrupted by, for example, transcription or keying MSAccess database which had been compiled by the

errors, between its initial collection and its use previous holders of the property, AusTinMining. This

for Mineral Resource estimation purposes. data was re-imported into an MSAccess database to

allow for some error checking.

* Data validation procedures used.

* The TMPL recent drilling data was supplied as a

series of CSV files which H&SC imported into the same

MSAccess database as used for the Newmont drilling.

* TMPL digital logging process involves android based

Lenovo Tab M10 HD tablets. The tablet has a rugged

plastic and rubber waterproof case and requires a pin

code to unlock. The tablet has various templates

stored on it for recording different data sets (RC

logging, DDH logging, RQD's etc). All templates are

MSExcel spreadsheets and operate via manually typing

in the data on the tablet or utilizing pre-filled

drop-down boxes.

* Validation of the Newmont drilling by H&SC included

original assay and logging sheet checks against the

supplied digital data for a set of 13 randomly

selected drillholes. Minor typographic errors were

noted and fixed. Some of the methodology of

transcribing the hard copy data could be improved.

* H&SC completed some independent validation of the new

data to ensure the drill hole database is internally

consistent. Validation included checking that no

assays or geological logs occur beyond the end of

hole and that all drilled intervals have been

geologically logged. The minimum and maximum values

of assays and density measurements were checked to

ensure values are within expected ranges. Further

checks include testing for duplicate samples and

overlapping sampling or logging intervals.

* H&SC takes responsibility for the accuracy and

reliability of the data used in the Mineral Resource

estimates.

* H&SC used the historic local N-S orthogonal grid for

all interpretation and modelling work. For subsequent

mine planning studies this work was rotated and

converted to MGA94 Zone 56 using the Surpac 2 point

grid transformation option.

============================================================

Site visits

* Comment on any site visits undertaken by the * Two site visits were completed by Simon Tear of H&SC,

Competent Person and the outcome of those visits. in October 2022 during the recent drilling campaign

and again in June 2023 to review newly drilled

diamond core and other aspects of the sample data

* If no site visits have been undertaken indicate why collection phase.

this is the case.

* The October 2022 visit involved inspection of both

ongoing diamond and RC drilling operations. A check

on collar coordinates for 20 holes including both

historic and recent holes was completed. A review of

chip trays for 2 RC drillholes was also undertaken.

Inspection of the trial adit and its recent TMPL

sampling was also completed.

* The June 2023 visit involved inspection of 6 DD holes

from the recent hole twinning programme designed by

TMPL to test previous results from the Newmont

drilling. The inspection confirmed the geology,

mineralisation and assay grades at Taronga as

comprising thin, cassiterite-bearing veins, in a

sheeted vein system, hosted within hornfels rock.

Geological

interpretation * Confidence in (or conversely, the uncertainty of ) * The mineralisation comprises North Pit and South Pit

the geological interpretation of the mineral deposit. zones with a relatively lower grade zone in between

(partly the result of a lack of drilling and a change

in the host lithology with possibly a change in the

* Nature of the data used and of any assumptions made. rheological properties of the host).

* The effect, if any, of alternative interpretations on * The North Pit comprises two higher grade elongate tin

Mineral Resource estimation. zones with an enveloping zone of lower grade tin

forming a single mass. Whilst the South Pit comprises

up to five distinct and well separated elongate

* The use of geology in guiding and controlling Mineral tin-enriched zones with parallel strike and dip.

Resource estimation.

* The host rock is the result of relatively uniform

* The factors affecting continuity both of grade and hornfelsing of either siltstone or sandstone.

geology.

* Mineralisation consists of quartz-cassiterite veins

from hairline fractures to veins up to 5-10cm thick.

Chalcopyrite and arsenopyrite disseminations, blebs

and veinlets are commonly associated with the

tin-bearing veins. Minor pyrite zones are

occasionally visible.

* There is no obvious visible lithological or

structural control to the tin mineralisation, save

for a broad NE/SW striking enriched zone, presumably

some form of structural corridor. The system has been

interpreted as a sheeted vein deposit.

* No geological interpretation per se has been

completed as the tin grades define the tin

mineralization in the rather amorphous-looking

hornfels. Any wireframe for the tin mineralization

would ultimately be a simple grade shell.

* There is insufficient data to define with confidence

any specific or significant fault structure.

* A review of multi-element data from the recent

drilling has allowed for the interpretation of a

sodium depletion zone corresponding with a weak

potassic enrichment as matching the definition of the

tin mineralisation. The study also highlighted a

lithogeochemical difference between the host rocks

for the South and North Pits.

* An oxidation surface, reflecting both complete and

partial weathering, was developed by H&SC from logged

historic and recent drilling data, with support from

the multielement assays. Confidence in the surface is

moderate as the data is incomplete and there is

uncertainty as to whether weathering has formed a

broad, horizontal front roughly parallel to the

surface topography and/or that there are more

isolated, penetrative fingers of weathering to

greater depths via fault structures.

============================================================

Dimensions

* The extent and variability of the Mineral Resource * The Mineral Resources have a strike length of around

expressed as length (along strike or otherwise), plan 2.7km in a north easterly (grid north) direction. The

width, and depth below surface to the upper and lower plan width of the resource varies from 200m to 400m

limits of the Mineral Resource. with an average of around 270m. The upper limit of

the mineralisation is exposed with the fresh rock

generally occurring around 20m below surface and the

lower limit of the Mineral Resources extends to an

approximate depth of 550m below surface (400mRL).

* The lower limit to the Mineral Resource is a direct

function of the depth limitations to the drilling in

conjunction with the search parameters. The

mineralisation is open at depth and laterally to the

southwest, beyond the South Pit zone.

Estimation

and modelling * The nature and appropriateness of the estimation * The drillhole database was composited with no

techniques technique(s) applied and key assumptions, including constraints to 1m composites covering the whole of

treatment of extreme grade values, domaining, the prospect.

interpolation parameters and maximum distance of

extrapolation from data points. If a computer

assisted estimation method was chosen include a * Ordinary Kriging (OK) with two search domains was

description of computer software and parameters used. used to complete the tin grade estimation using

H&SC's in-house GS3M modelling software. The

geological interpretation and block model creation

* The availability of check estimates, previous and validation was completed using the Surpac mining

estimates and/or mine production records and whether software. H&SC considers OK to be an appropriate

the Mineral Resource estimate takes appropriate estimation technique for the type of mineralisation

account of such data. and extent of data available. The tin composite data

has a relatively low coefficient of variation of

approximately 1.6 (CV = standard deviation divided by

* The assumptions made regarding recovery of the mean).

by-products.

* Regression equations based on newly available assay

* Estimation of deleterious elements or other non-grade data were used to estimate missing copper, arsenic

variables of economic significance (eg sulphur for and sulphur composite values. The arsenic and sulphur

acid mine drainage characterisation). datasets are a lot smaller in number compared to the

copper and silver data. Correlation between the

various elements was modest to weak but generated

* In the case of block model interpolation, the block regression equations based on the tin grade, using

size in relation to the average sample spacing and the Conditional Expectation technique, resulted in

the search employed. plausible outcomes for Cu, As, Ag & S. It should be

noted that the copper, arsenic, silver and sulphur

are not reported as part of the Mineral Resources and

* Any assumptions behind modelling of selective mining that the numbers are generated from less data than

units. that used in the tin Mineral Resources; the elements

were modelled to allow for waste rock

characterisation. OK was also used to model these

* Any assumptions about correlation between variables. other elements.

* Description of how the geological interpretation was * A total of 35,176 1m composites, excluding residuals

used to control the resource estimates. (137), were generated from the drillhole database and

modelled for tin, copper, arsenic, silver & sulphur.

* Discussion of basis for using or not using grade

cutting or capping. * Grade interpolation was unconstrained, except by the

search parameters and the variography, in

acknowledgement of the gradational nature to the

* The process of validation, the checking process used, margins of the tin mineralisation and the abundance

the comparison of model data to drill hole data, and of peripheral assays.

use of reconciliation data if available.

* There were very minor zones of unsampled core which

were generally surrounded by very low grades and

therefore did not require the insertion of very low

grades. These areas were invariably allocated very

low block grades from the subsequent grade

interpolation.

* The base of oxidation was treated as a soft boundary.

No cover surface was created as the mineralisation is

outcropping and is exposed in many places along its

ridge line and flanks.

* No top-cutting was applied as extreme values were

considered by H&SC as not significant and therefore

top-cutting was considered unnecessary.

* An OK check model using the same composite data was

completed using the OK option in Surpac. The outcome

confirmed the original model. A check Multiple

Indicator Kriging model (in the GS3M software) was

completed using the same composite data. Again the

outcome confirmed the original model. An OK check

model without the JACRO composite data yielded very

similar outcomes to the original Measured and

Indicated Resources.

* Block dimensions are 5m by 10m by 5m (Local E, N, RL

respectively) with no sub-blocking. The north

dimension was chosen as it is around half to a third

of the nominal drillhole distances in the detailed

drilled area of the South Pit. The east dimension was

chosen to take into account the geometry and

thickness of the mineralisation in the South Pit. The

vertical dimension was chosen to reflect the sample

spacing and possible mining bench heights and to

allow for flexibility in potential mining scenarios.

* Two search domains were employed, one for the South

Pit (domain 1) and another for the North Pit (domain

2) respectively, reflecting a modest change in strike

between the two zones.

* All elements were modelled as a combined dataset. 5

search passes were employed with progressively larger

radii or decreasing data point criteria. The Pass 1

used radii of 35m by 35m by 5m (along strike, down

dip and across mineralisation respectively), Passes

2, 3 and 4 used 50m by 50m by 10m, 70m by 70m by 10m

& 100m by 100m by 20m respectively, Minimum number of

data was 12, maximum number of data was 32 with a

minimum of 4 octants. A fifth pass used 100m by 100m

by 20m with a minimum of 6 data points from at least

2 octants.

* The maximum extrapolation for the Mineral Resources

was in the order of 100m down dip and 100m along

strike to the NE.

* The resource estimates are controlled by the data

point distribution, the variography, block size and

the search ellipse. Conventional use of wireframes to

control the mineralisation was not considered

necessary. A preliminary resource model had been

completed prior to the 2022/3 drilling to ascertain

likely dilution grades for peripheral material to the

main tin mineralisation with the subsequent infill

drilling results generally matching this preliminary

model.

* The new block model was reviewed visually by H&SC and

it was concluded that the block model fairly

represents the grades observed in the drill holes.

H&SC also validated the block model using a variety

of summary statistics and statistical plots. No

issues were noted.

* Comparison with the 2013 resource estimates indicated

a larger tonnage for the 2023 Mineral Resource at

approximately the same tin grade. The main increase

in tonnage was for the South Pit due to the modelling

method extrapolating much further than the rather

tight wireframes that were used previously to

constrain the mineralisation. The increase is also

mainly the result of the additional exploratory TMPL

drilling to the south west. Also greater confidence

in the Newmont drilling data has been achieved with

the twin holes and the repeat adit sampling to allow

for Measured Resource to be categorised.

============================================================

Moisture

* Whether the tonnages are estimated on a dry basis or * Tonnages of the Mineral Resources are estimated on a

with natural moisture, and the method of dry weight basis.

determination of the moisture content.

Cut-off

parameters * The basis of the adopted cut-off grade(s) or quality * The resources are reported at a tin cut-off of 0.05%

parameters applied. based on the outcome of a recently completed

throughput study by independent mining consultants

AMDAD of Brisbane.

* The cut-off grade at which the resource is quoted

reflects the intended bulk-mining approach.

============================================================

Mining

factors * Assumptions made regarding possible mining methods, * The Mineral Resources were estimated on the

or assumptions minimum mining dimensions and internal (or, if assumption that the material is to be mined by open

applicable, external) mining dilution. It is always pit using a bulk mining method.

necessary as part of the process of determining

reasonable prospects for eventual economic extraction

to consider potential mining methods, but the * The proposed mining method is a conventional drill &

assumptions made regarding mining methods and blast, truck & excavator with extracted material sent

parameters when estimating Mineral Resources may not to an on-site ROM pad with a processing plant

always be rigorous. Where this is the case, this adjacent to the planned pit.

should be reported with an explanation of the basis

of the mining assumptions made.

* Minimum mining dimensions are envisioned to be around

10m by 5m by 5m (strike, across strike, vertical

respectively). The block size is relatively larger

than the likely minimum mining dimensions.

* The resource estimation includes internal mining

dilution.

Metallurgical

factors * The basis for assumptions or predictions regarding * Industry standard processing is envisaged for the

or assumptions metallurgical amenability. It is always necessary as deposit.

part of the process of determining reasonable

prospects for eventual economic extraction to

consider potential metallurgical methods, but the * A processing flowsheet has been proposed that will

assumptions regarding metallurgical treatment involve comminution, gravity separation and

processes and parameters made when reporting Mineral floatation to generate a tin concentrate.

Resources may not always be rigorous. Where this is

the case, this should be reported with an explanation

of the basis of the metallurgical assumptions made. * The hardness of ore material is at a manageable

level.

* Initial testwork has demonstrated that penalty

elements can be limited to acceptable levels.

* Waste products from processing can suitably be dealt

with.

============================================================

Environmen-tal

factors * Assumptions made regarding possible waste and process * The deposit lies within hilly, open country typical

or assumptions residue disposal options. It is always necessary as of the NSW Northern Tablelands.

part of the process of determining reasonable

prospects for eventual economic extraction to

consider the potential environmental impacts of the * Land use is predominantly cattle grazing on native or

mining and processing operation. While at this stage improved pasture.

the determination of potential environmental impacts,

particularly for a greenfields project, may not

always be well advanced, the status of early * There are limited flat areas for waste and tailings

consideration of these potential environmental disposal. Most likely sites are north of a ridge line

impacts should be reported. Where these aspects have just north of the proposed pits.

not been considered this should be reported with an

explanation of the environmental assumptions made.

* Thera are a small number of creeks with seasonal

flows.

* The host rocks have relatively low sulphur contents.

* Some of the mined material has acid neutralising

capacity.

* Baseline data collection of a variety of

environmental parameters is in progress e.g.

biodiversity, surface water and groundwater.

Bulk density

* Whether assumed or determined. If assumed, the basis * Original bulk density measuring work completed by

for the assumptions. If determined, the method used, Newmont used single pieces of core subjected to the

whether wet or dry, the frequency of the measurements weight in air/weight in water method (Archimedes

, Principle). The result was a set of default

the nature, size and representativeness of the densities: 2.8t/m(3) for 'ore' (>0.1%Sn) and

samples. 2.7t/m(3) for waste.

* The bulk density for bulk material must have been * The 2013 Mining One estimate used a global default of

measured by methods that adequately account for void 2.75t/m(3) .

spaces (vugs, porosity, etc), moisture and

differences between rock and alteration zones within

the deposit. * Work completed by TMPL used a weight in air/weight in

water procedure on 415 samples of diamond core. The

average value was 2.75t/m(3) .

* Discuss assumptions for bulk density estimates used

in the evaluation process of the different materials.

* Core inspection indicated very competent core with no

significant vughs.

* H&SC subdivided the samples using the base of

oxidation surface to ascertain the impact of surface

weathering on the density. The impact was marginal

with slightly lower values in the oxidized zone as

would be expected. Default values were inserted into

the block model for oxide and fresh rock that had

interpolated grades for the North Pit, and the

Hillside and Payback subdivisions of the South Pit.

* A density of 2.65t/m(3) was applied to all 'waste'

i.e. blocks with no interpolated tin grade.

============================================================

Classification

* The basis for the classification of the Mineral * The classification of the resource estimates is based

Resources into varying confidence categories. on the data point distribution which is a function of

the drillhole spacing.

* Whether appropriate account has been taken of all

relevant factors (ie relative confidence in * A defined shape was used for the Measured Resource in

tonnage/grade estimations, reliability of input data, the North Pit in order to remove a 'spotted dog'

confidence in continuity of geology and metal values, effect.

quality, quantity and distribution of the data).

* Other aspects have been considered in the

* Whether the result appropriately reflects the classification including, the style of mineralisation

Competent Person's view of the deposit. ,

the geological model, validation of the historic

drilling, sampling methods and recoveries,

non-sampled zones, the QAQC programme and results and

comparison with previous resource estimates.

* H&SC believes the confidence in tonnage and grade

estimates, the continuity of geology and grade, and

the distribution of the data reflect Measured,

Indicated and Inferred categorisation. The estimates

appropriately reflect the Competent Person's view of

the deposit. H&SC has assessed the reliability of the

input data and takes responsibility for the accuracy

and reliability of the data used to estimate the

Mineral Resources.

Audits * No audits or reviews have been completed.

or reviews * The results of any audits or reviews of Mineral

Resource estimates.

============================================================

Discussion

of relative * Where appropriate a statement of the relative * No statistical or geostatistical procedures were used

accuracy/ accuracy and confidence level in the Mineral Resource to quantify the relative accuracy of the resource.

confidence estimate using an approach or procedure deemed The global Mineral Resource estimates of the Taronga

appropriate by the Competent Person. For example, the deposit are moderately sensitive to higher cut-off

application of statistical or geostatistical grades but does not vary significantly at lower

procedures to quantify the relative accuracy of the cut-offs.

resource within stated confidence limits, or, if such

an approach is not deemed appropriate, a qualitative

discussion of the factors that could affect the * The relative accuracy and confidence level in the

relative accuracy and confidence of the estimate. Mineral Resource estimates are considered to be in

line with the generally accepted accuracy and

confidence of the nominated Mineral Resource

* The statement should specify whether it relates to categories. This has been determined on a qualitative

global or local estimates, and, if local, state the ,

relevant tonnages, which should be relevant to rather than quantitative, basis, and is based on the

technical and economic evaluation. Documentation Competent Person's experience with similar deposits

should include assumptions made and the procedures and geology.

used.

* The Mineral Resource estimates are considered to be

* These statements of relative accuracy and confidence accurate globally, but there is some uncertainty in

of the estimate should be compared with production the local estimates due to the current drillhole

data, where available. spacing, a lack of geological definition in certain

places eg fault zones and penetration depths of

surface weathering,

* No mining of the deposit has taken place, so no

production data is available for comparison.

=============== ============================================================ ============================================================

This information is provided by RNS, the news service of the

London Stock Exchange. RNS is approved by the Financial Conduct

Authority to act as a Primary Information Provider in the United

Kingdom. Terms and conditions relating to the use and distribution

of this information may apply. For further information, please

contact rns@lseg.com or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms

and conditions, to analyse how you engage with the information

contained in this communication, and to share such analysis on an

anonymised basis with others as part of our commercial services.

For further information about how RNS and the London Stock Exchange

use the personal data you provide us, please see our Privacy

Policy.

END

MSCGPUUGBUPWPUW

(END) Dow Jones Newswires

September 14, 2023 02:00 ET (06:00 GMT)

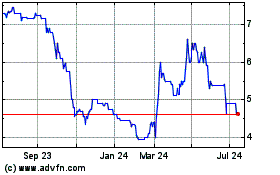

First Tin (LSE:1SN)

Historical Stock Chart

From Dec 2024 to Jan 2025

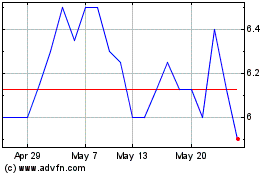

First Tin (LSE:1SN)

Historical Stock Chart

From Jan 2024 to Jan 2025