TIDMADT1

RNS Number : 3803X

Adriatic Metals PLC

20 December 2023

20 December 2023

Adriatic Metals PLC

("Adriatic Metals" or the "Company")

UPDATED ORE RESERVES ESTIMATE FOR RUPICE

HIGHLIGHTS

-- Updated ore reserve estimate for the 100%-owned Rupice

silver-zinc-lead-gold deposit in Bosnia and Herzegovina has grown

to: 13.8Mt at 187g/t Ag, 5.2% Zn, 3.3% Pb, 1.4g/t Au, 0.5% Cu and

0.2% Sb containing an estimated 83Moz of silver, 723Kt of zinc,

457Kt of lead, 640Koz of gold, 64Kt of copper and 24kt of

antimony.

-- Contained ore reserve tonnes have increased by 89% since the

previous Ore Reserve estimate stated as at July 2021.

-- The significant increase in ore reserves underpins an 18-year

mine life which now extends until 2041 based on nominal throughput

capacity of 800,000tpa.

-- The Indicated and Inferred Mineral Resource estimate ("MRE")

for Rupice as reported on 27 July 2023 is: 21.1 Mt at 156 g/t Ag,

1.2 g/t Au, 4.3% Zn, 2.8% Pb, 0.4% Cu, 27% BaSO(4) (reported above

a cut-off grade of 50 g/t AgEq) containing 105 Moz Ag, 789koz Au,

913kt Zn, 581kt Pb, 88kt Cu and 39kt Sb.

-- Exploration drilling continues to successfully identify

further high-grade mineralization at Rupice and Rupice Northwest, A

further MRE update is scheduled for H1 2024.

Paul Cronin, Adriatic's Managing Director and CEO,

commented,

"We are extremely pleased to announce the updated Ore Reserves

at our flagship Rupice mine have increased by 89%.

The Ore Reserves have been derived from the JORC Mineral

Resources statement announced on 27 July 2023 and demonstrate that

Rupice is a world class deposit. Exploration drilling has continued

this year, and we believe there is potential to add further

resources at Rupice, as well as at our adjacent targets.

The updated Ore Reserve was completed to a very high standard

using industry best practice and methodologies. It sets a solid

foundation for mine planning and future production growth with

mining now scheduled at Rupice Northwest.

The completion of updated Ore Reserves at Rupice is an important

step forward for Adriatic as we maximise the value of this asset

for all of our stakeholders over the next 18 years and beyond."

Adriatic Metals PLC (ASX:ADT, LSE:ADT1, OTCQX:ADMLF), is pleased

to announce the updated Rupice Mine Ore Reserves, as part of the

fully owned Vares Silver Project in Bosnia & Herzegovina

totalling 13.8Mt at 187g/t Ag, 5.2% Zn, 3.3% Pb, 1.4g/t Au, 0.5% Cu

and 0.2% Sb containing an estimated 83Moz of silver, 723Kt of zinc,

457Kt of lead, 640Koz of gold, 64Kt of copper and 24kt of

antimony.

Table 1 : Updated Rupice Ore Reserve

Classification Tonnes Zn Pb Au Ag Cu Sb

Mt % % g/t g/t % %

Proved - - - - - - -

------- ---- ---- ----- ----- ---- ----

Probable 13.8 5.2 3.3 1.4 187 0.5 0.2

------- ---- ---- ----- ----- ---- ----

Total 13.8 5.2 3.3 1.4 187 0.5 0.2

------- ---- ---- ----- ----- ---- ----

The updated ore reserve estimate was completed by AMC

Consultants (AMC) with the assistance of the Adriatic technical

services team using industry best practice. The final signed off

report from AMC was received on 12 December 2023. The Rupice Ore

Reserve has been updated based on the updated Mineral Resource (as

announced on 27 July 2023) and is shown in Table 2. The Mineral

Resource estimate has been reported in accordance with the JORC

Code. The Mineral Resource is reported inclusive of Ore

Reserves.

Table 2: Rupice Mineral Resource estimate by classification - 27

July 2023 (AMC, 2023) cut-off grade of 50 g/t AgEq applied

Classification Tonnes Zn Pb Au Ag Cu Ba Sb

Mt % % g/t g/t % % %

Indicated 18.3 4.6 2.9 1.3 168 0.4 30 0.2

------- ---- ---- ----- ----- ---- --- ----

Inferred 2.8 2.4 1.6 0.5 75 0.2 13 0.1

------- ---- ---- ----- ----- ---- --- ----

Total 21.1 4.3 2.8 1.2 156 0.4 27 0.2

------- ---- ---- ----- ----- ---- --- ----

Notes:

Mineral Resources are based on JORC Code 2012 definitions.

Metal prices, payabilities, and recoveries have been

applied.

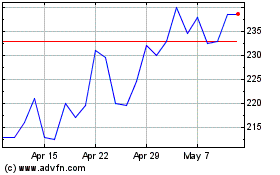

The majority of the addition to reserves has come from the

Rupice Northwest Orebody, with some increase in the Rupice reserve

tonnage as shown in Figure 1. It is worth noting that infill and

exploration drilling after the July 2023 MRE are not incorporated

into these ore reserve estimates. The significant increase in ore

reserves underpins an 18-year mine life, which now extends until

2041. This is an increase of 8 years from the initial reserve

announced as part of the 2021 Definitive Feasibility Study ("DFS")

and shows that Rupice has outstanding potential for further

growth.

Figure 1: Rupice Ore Reserve tonnage variance

For further information please visit: www.adriaticmetals.com ;

email: info@adriaticmetals.com , @AdriaticMetals on Twitter; or

contact:

Adriatic Metals PLC

Paul Cronin / Klara Kaczmarek Via Buchanan

Buchanan Tel: +44 (0) 20 7466 5000

Bobby Morse / Oonagh Reidy adriatic@buchanan.uk.com

RBC Capital Markets (Joint Corporate Broker)

James Agnew / Jamil Miah Tel: +44 (0) 20 7653 4000

Stifel Nicolaus Europe Limited (Joint

Corporate Broker)

Ashton Clanfield / Callum Stewart Tel: +44 (0) 20 7710 7600

Citadel Magnus

Cameron Gilenko Tel: +61 2 8234 0100

ABOUT ADRIATIC METALS

Adriatic Metals PLC (ASX:ADT, LSE:ADT1, OTCQX:ADMLF) is a

precious and base metals developer that is advancing the

world-class Vares Silver Project in Bosnia & Herzegovina, as

well as the Raska Zinc-Silver Project in Serbia. The Vares Silver

Project is fully funded to production, which is expected in Q1

2024. Concurrent with ongoing construction activities, the Company

continues to explore across its highly prospective 44km(2)

concession package.

There have been no material changes to the assumptions

underpinning the forecast financial information derived from the

production target in the 19 August 2021 DFS announcement and these

assumptions continue to apply and have not materially changed.

Adriatic Metals is not aware of any new information or data that

materially affects the information included in the announcement of

the updated Mineral Resource Estimate announced on 1 September 2020

and all material assumptions and technical parameters underpinning

the Mineral Resource Estimate continue to apply and have not

materially changed.

MARKET ABUSE REGULATION DISCLOSURE

The information contained within this announcement is deemed by

the Company (LEI: 549300OHAH2GL1DP0L61) to constitute inside

information for the purpose of Article 7of EU Market Abuse

Regulation (EU) No. 596/2014 as it forms part of UK domestic law by

virtue of the European Union (Withdrawal) ACT 2018, as amended. The

person responsible for arranging and authorising the release of

this announcement on behalf of the Company is Paul Cronin, Managing

Director and CEO.

RUPICE ORE RESERVE

STATEMENT AND EXPLANATORY Notes

Location

The Rupice deposit is located near the mining town of Vares,

approximately 50 km north of the capital Sarajevo in Bosnia and

Herzegovina and approximately 60 minutes by car; first via the

Sarajevo - Tuzla freeway to Podlugovi, then a sealed road to Vares.

The town of Vares is the administrative centre for the Vares

District. The Rupice operation consists of an underground mine and

a surface mineral processing plant.

The Rupice deposit is located within a single concession

comprising three separate licence areas: one at Rupice in the west,

and two at Veova č a in the east (Figure 2.1). The initial

concession area in total was 280.54 ha: 83.05 ha at Rupice, and

197.49 ha at Veova č a, and this has since expanded to a total of

865.3 ha: 535.2 ha at Rupice and 330.1 ha at Veova č a (Figure

2.2).

Figure 2.1: Rupice Project location

Figure 2.2: Rupice Licence location

RUPICE Resource Details

The Rupice July 2023 Mineral Resources statement was made public

on 27 July 2023 via an ASX announcement titled: "Mineral Resource

Estimate Grows Indicated Tonnes by 93%" and a LSE announcement of

the same date and title. A summary of the information contained in

the release is outlined below.

For the 2023 MRE Rupice and Rupice Northwest ('RNW'), a total of

287 diamond drill holes for a total of 76,935m define the current

limits of the known mineralization. Up to mid-2022, the deposit was

drilled and sampled using diamond drill holes on a nominal 20m by

20m spacing. From mid-2022 to May 2023, the drill hole spacing was

widened to a 40m x 30m spacing across RNW reflecting the robust

continuity of the stratabound mineralization along and across

strike. Drilling has defined a combined Rupice and RNW mineralized

system having a strike length of >900m and an across-strike

width of >350m.

The geological controls on polymetallic mineralization at Rupice

and RNW were interpreted using lithological, alteration, structural

and geochemical data available from logging and assays. Separate

solids for each lithology from surface to below mineralization were

modelled. Massive and semi-massive visually logged sulphides where

combined to form coherent mineralized solids. The trends in

mineralization were matched to modelled stratigraphic units

controlling the distribution of mineralization.

A block model was constructed, constrained by the interpreted

mineralized envelopes. A parent cell size of 5m(E) x 5m(N) x 5m(RL)

was adopted with standard sub-celling to 1m(E) x 1m(N) x 1m(RL) to

maintain the volumetric resolution of the mineralized lenses.

Grades for all ten elements were interpolated into the empty

block model using the Ordinary Kriging method and a "parent block

estimation" technique, i.e., all sub-cells within a parent cell

were populated with the same grade. The ordinary kriging (OK)

process was performed at different search radii until all cells

were interpolated. The search radii were determined by means of the

evaluation of the semi-variogram parameters, which determined the

kriging weights to be applied to samples at specified distances.

Hard boundaries were honoured between each modelled lens and each

grade domain. Block grades were validated both visually and

statistically and all modelling was completed using Micromine

software. The Rupice deposit has reasonable prospects for eventual

economic extraction based on a number of factors. Metallurgical

test work by Wardell Armstrong International ("WAI") has confirmed

that Rupice mineralization is amenable to flotation processes. The

cut-off grade adopted for reporting (50 g/t Ag equivalent) is

considered reasonable given the Mineral Resource will be exploited

by underground mining methods and potentially processed using

flotation techniques to produce a concentrate or as a direct

shipping crushed product for massive ores. Concentrate off-take

agreements and transport logistics have all been negotiated and

Adriatic Metals has secured long-term tenure across all

tenements.

RUPICE REsERVE DETAILS

Estimation Methodology

The 2023 Ore Reserve is summarised in Table 1. As there is no

Measured Mineral Resource, no Proved Ore Reserves are estimated.

During the stope optimisation process, a maximum of 5% inferred

material is allowed to be included in individual stope shapes.

Overall, less than 1% of the Ore Reserve is in the inferred

category. Any inferred material was given a zero grade. No stoping

had taken place at the cut-off date of this report and while

development stockpiling has commenced, volumes are not sufficient

for any reasonable grade reconciliation to commence. The Ore

Reserve is reported on a 100% basis. A cut-off is applied using an

NSR of US$68/t ore. Adriatic has demonstrated the Vares Project has

a positive net present value (NPV) supporting the statement of Ore

Reserves. The previous Ore Reserve is summarised in Table 1.1 .

Table 1: New Rupice Ore Reserve

Classification Tonnes Mt Zn Pb Au Ag Cu Sb

% % g/t g/t % %

Proved - - - - - - -

----------- ----- ----- ------ ------ ----- -----

Probable 13.8 5.2 3.3 1.4 187 0.5 0.2

----------- ----- ----- ------ ------ ----- -----

Total 13.8 5.2 3.3 1.4 187 0.5 0.2

----------- ----- ----- ------ ------ ----- -----

Notes:

Mineral Resources are based on JORC code definitions. Metal

prices, payabilities, and recoveries have been applied.

Table 1.1: Previous Ore Reserve 19 August 2021

Classification Tonnes Mt Zn Pb Au Ag Cu Sb

% % g/t g/t % %

Proved - - - - - - -

----------- ----- ----- ------ ------ ----- -----

Probable 7.3 5.7 3.6 1.9 202 0.6 0.2

----------- ----- ----- ------ ------ ----- -----

Total 7.3 5.7 3.6 1.9 202 0.6 0.2

----------- ----- ----- ------ ------ ----- -----

The Mineral Resource estimate has been reported in accordance

with the JORC Code ( Table 3 ). The Mineral Resource is reported

inclusive of Ore Reserves.

Table 2: Rupice Mineral Resource estimate by classification - 27

July 2023 (AMC, 2023) cut-off grade of 50 g/t AgEq applied

Classification Tonnes Zn Pb Au Ag Cu Ba Sb

Mt % % g/t g/t % % %

Indicated 18.3 4.6 2.9 1.3 168 0.4 30 0.2

------- ----- ----- ------ ------ ----- ---- -----

Inferred 2.8 2.4 1.6 0.5 75 0.2 13 0.1

------- ----- ----- ------ ------ ----- ---- -----

Total 21.1 4.3 2.8 1.2 156 0.4 27 0.2

------- ----- ----- ------ ------ ----- ---- -----

The Ore Reserve estimate was completed internally by Adriatic

under the direction of the Competent Person ('CP') who was assisted

by key technical staff at Adriatic and AMC. Adriatic has used a LOM

approach, whereby all mining areas were re-evaluated using the new

NSR calculation to determine economic mining areas of which the

Rupice Northwest Zone was an extension to existing operation. AMC

considers this approach reasonable for the 2023 Ore Reserve.

AMC ran multiple scenarios, testing various mining and metal

prices within an offtake and flotation parameters. For the

reserves, metal prices of $23.00/oz Ag, 2,450/t Zn, $2,280/t Pb,

$8,335/t Cu, $1,912/oz Au and $11,525/t Sb USD were used. A mining

cost of $35/t US was used for the cost model, all other costs

remained as per the DFS.

Competent Person

The Competent Person for the 2023 Ore Reserves is Dominic

Claridge, Principal Mining Engineer, an employee of AMC. Dominic

satisfies the requirements to act as a Competent Person in that he

has the relevant experience, has visited site for the basis of a

sign-off and is a Fellow of the Australian Institute of Mining and

Metallurgy (FAusIMM).

Mining

At Rupice, mining occurs from two lenses (Rupice Main and Rupice

Northwest) with all ore hauled to a surface stockpile, before being

crushed and transferred via surface trucks to the Vares Processing

Plant.

The mining method is a combination of mechanized, trackless

underground mining using longitudinal longhole open-stoping (LLHOS)

and transverse longhole open-stoping (TLHOS) with footwall decline

access. Access to the underground workings is via two declines

developed from the surface. Orebody access is via capital

development of ramps, level access drives, and footwall drives.

Figure 3.1: Mine design looking west - longitudinal section view

(Adriatic Metals, 2023 Deswik Mine Planning Output)

Figure 3.2: Mine design looking east (Adriatic Metals, 2023

Deswik Output)

Global constraints are set up within mine planning software to

schedule mining physicals. The key parameters are listed in Table

6.

Table 6: Schedule parameters

Constant Unit Rate Comment

NSR Cut-off US$/t 68 Economic Stopes

------------------ ---------------- ------------------------------------

FW Dilution Factor m 1.0 Last Stope to FW Diluted

------------------ ---------------- ------------------------------------

HW Dilution Factor m 2.0 Last stope to HW Diluted

------------------ ---------------- ------------------------------------

Stope recovery % 95

------------------ ---------------- ------------------------------------

Table 7: LOM schedule resource rates and fleet number

Resource Unit Rate / Month Mining Fleet

Numbers

Jumbo m/month/heading 160 3

---------------------------- ------------------------ -------------------------------

Jumbo m/month/jumbo 160 3

---------------------------- ------------------------ -------------------------------

Production drill m/month 5,000 2

---------------------------- ------------------------ -------------------------------

Cablebolt m/month 2,000 1

---------------------------- ------------------------ -------------------------------

Stope loading t/day 1,200 4

---------------------------- ------------------------ -------------------------------

Backfill loading t/day 600 1

---------------------------- ------------------------ -------------------------------

Table 8: Dilution factors

Dilution Unit Dilution (%)

HW and FW Dilution % 8

----------------- ------------------------

Paste Overbreak

Dilution % 5

----------------- ------------------------

Total Dilution % 13

----------------- ------------------------

Processing

The Vares Processing Plant ('VPP') has a nominal capacity of

800,000tpa, and applies three-stage crushing, grinding, flotation

and filtration to produce two saleable concentrates (Ag/Pb and Zn).

Concentrates will be transported via rail to the Port of Plo č e

for shipment to smelters. The Ag/Pb concentrate contains payable

Ag, Pb, Zn, Cu, Sb and Au (Sb is payable if over 2% and if Ag is

over 2,500g/t and Zn is payable if over 10%). The Zn concentrate

contains payable Zn, Ag, and Au. Figure 4 shows the basic flowsheet

below.

Figure 4 : Vares Process Plant flowsheet (Ausenco, 2021)

The plant consists of the following circuits:

-- Three-stage crushing:

1. Primary jaw crusher, grizzly screen on feed, P80 of 121 mm.

2. Secondary cone crusher, open circuit, P80 of 51 mm.

3. Tertiary cone crusher, P80 of 12 mm, in closed circuit with triple-deck screen.

4. Final crushed ore (triple-deck screen undersize) with P80 of 7 mm.

5. Crushing plant has capacity to produce aggregate for underground backfill

-- Crushed ore handling and storage:

1. Coarse ore storage bins (two), 2,260 t each.

2. Each providing 23 hours of plant feed at the nominal plant

feed rate of 110 wtph (wet tonnes per hour).

-- Ball mill grinding circuit:

1. 4.3m by 7.5m mill with 2,400 kW motor.

2. Product P80 of 40 um.

-- Flotation:

Silver-lead flotation:

Roughers.

-- Concentrate regrind to P 80 of 10 um using 1500 kW

ISAMill.

-- Three-stage cleaners.

Zinc flotation:

Roughers.

-- Concentrate regrind to P 80 of 20 um using 500 kW

ISAMill.

-- Three-stage cleaners.

-- Concentrate handling by means of thickening, filtration,

container loading and truck transportation from site for

silver-lead and zinc concentrates.

-- Tailings handling by means of thickening, filtration to 9.3%

w/w, loading and transport by truck to backfill for the underground

backfill or to TSF.

Adriatic continued to work with Ausenco to upgrade the circuit

design upon completion of the DFS. Additional flotation capacity in

the form of Jameson Cells has been provided after the regrind mills

and ahead of the cleaner cells to improve recoveries and

concentrate grades. This additional cleaner capacity for both the

lead and zinc circuits reduces the risk of metal loss during

periods of high feed grade which can be expected at Rupice. Figure

5 shows the upgraded process flowsheet.

Figure 5: Rupice process plant - with Jameson cells (Ausenco,

2023)

Process plant throughput

Key design criteria for the Vares Processing Plant are shown in

Table 9. Designed throughput is 800,000 tpa with operating

availability of 91.3% (8,000 operating hours per year). Operating

availability for the crushing plant is 65% (5,694 operating hours

per year), and 82% for concentrate/tailings filtration and handling

(7,200 operating hours per year). Adriatic in the process of

conducting formal studies to confirm throughput can be increased to

over 1Mtpa, to align with anticipated mine production. Operating

availability figures are customary for the processing industry and

appropriate for the Vares Processing Plant.

Design of the comminution circuit was based on the nominal power

requirement of average ore. The nominal BWi (hardness) selected was

10 kWh/t. The range of BWi calculated for the variability samples

was 4.7 kWh/t to 13.9 kWh/t and the BWi for the Year 1 composite

sample was 8.4 kWh/t.

High-grade ore with a BWi range of 6-7 kWh/t will be treated in

the early years. Adriatic and Ausenco have used a maximum feed rate

of 130 tph in the LOM production schedule resulting in throughputs

greater than 1.0 Mtpa from Year 6 to Year 10 and greater than the

nominal design of 0.8 Mtpa for all years from Year 4 to Year 15.

Adriatic and Ausenco are confident that the 30% increase above the

nominal throughput capacity in early years will be achieved due to

the preferential treatment of soft, high-grade ore in early years

of the Vares Project, and state that the throughput capacity - ore

hardness relationship will be confirmed by modelling. AMC concurs

with this assessment.

Metal recoveries and concentrate grades were derived using LOM

average grades and the Ausenco/Libertas models.

Table 9: Vares Processing Plant design criteria

Criteria Unit Value

Annual Throughput (Design) kt/a 800

====================== ===================================

Operating Days per Year D 365

====================== ===================================

Operating Availability - Crushing h/a 5694

====================== ===================================

Operating Availability - Grinding and

Flotation h/a 8,000

====================== ===================================

Operating Availability - Concentrate

and Tailings Handling h/a 7,200

====================== ===================================

Design Throughput - Crushing t/h (dry) 290

====================== ===================================

Design Throughput - Grinding and Flotation t/h (dry) 100

====================== ===================================

Design Throughput - Silver-Lead Concentrate

Filtration t/h (dry) 10

====================== ===================================

Design Throughput - Zinc Concentrate

Filtration t/h (dry) 12

====================== ===================================

Crushing Feed Size, 100% Passing mm 600

====================== ===================================

Crushing Product Size, 80% Passing -

Crushed Ore mm 7.12

====================== ===================================

Crushing Product Size, 100% Passing

- Paste Aggregate Fill mm 12

====================== ===================================

Crushing Product Size, 100% Passing

- Cemented Aggregate Fill mm 75

====================== ===================================

Grinding Product Size, 80% Passing um 40

====================== ===================================

Ball Mill Circulating Load % 250

====================== ===================================

Bond Ball Mill Work Index - Design kWh/t 9.5

====================== ===================================

Bond Abrasion Index - Design g 0.168

====================== ===================================

ROM Head Grade, Lead - Average % 2.9

====================== ===================================

ROM Head Grade, Copper - Average % 0.5

====================== ===================================

ROM Head Grade, Zinc - Average % 4.6

====================== ===================================

ROM Head Grade, Gold - Average g/t 1.37

====================== ===================================

ROM Head Grade, Silver - Average g/t 159

====================== ===================================

Metal Recovery Method - polymetallic sequential

flotation

====================== ===================================

Copper Recovery to Silver-Lead Concentrate % 81.2

====================== ===================================

Silver-Lead Concentrate Grade, Copper % Cu 7.4

====================== ===================================

Lead Recovery to Silver-Lead Concentrate % 87.4

====================== ===================================

Silver-lead Concentrate Grade, Lead % Pb 47.4

====================== ===================================

Silver Recovery to Silver-Lead Concentrate % 75.0

====================== ===================================

Silver-lead Concentrate Grade, Silver g/t 2266

====================== ===================================

Zinc Recovery to Zinc Concentrate % 80.2

====================== ===================================

Zinc Concentrate Grade % Zn 57.9

====================== ===================================

Source: Ausenco, 2021.

Permitting

Adriatic has committed to ensuring that the Vares Project will

comply with international best practice regarding environmental and

social standards. Environmental and groundwater management plans

have been submitted, approved and permitted. All major permits for

operations have been granted by the various competent authorities

within Bosnia & Herzegovina, however some more routine permits

and permits that would not ordinarily be issued until after the

commencement of production are outstanding and are expected to be

issued in due course.

Infrastructure

The Vares Municipality offers general trade services and

suppliers, and a considerable amount of 1980s mining

infrastructure, including a rail line which connects to the

national rail grid and inter alia, the Port of Plo č e in the

Republic of Croatia, where bulk commodities, including metal

concentrates are shipped. The capital of Bosnia and Herzegovina,

Sarajevo and its international airport is 60-minutes away.

The Vares Processing Plant is located on a brownfield site that

was previously used for mineral processing. It is located

approximately 25 km south-east of the town of Vares. A newly

constructed, sealed, all-weather road was completed in 2023 and is

available for inbound freight. Concentrates will be trucked 5 km

from the Plant to an existing rail siding where it will be

transloaded and then railed to the Port of Plo č e.

Power

A national electricity grid is operated and maintained by the

State company Electroprivreda d.o.o. Additionally, several power

lines run to the Veovaca open pit and abandoned processing facility

at Tisovci, and thereafter to a number of nearby villages. Most of

these lines deliver a 10 KVA service.

Power supply for the Rupice Surface Infrastructure is provided

from a new, buried 35 kV powerline which will run from Vares Majdan

regional sub-station, following the route of the new road between

Rupice Underground Mine and Vares Processing Plant, and

terminate/connect at the 35 kV incomer switchgear at the Rupice

main sub-station. From the new sub-station at Rupice, power is

reticulated at 10 kV on buried powerlines to the Rupice Surface

Infrastructure.

Water supply

Local water is supplied to all surrounding villages and is

provided by a public company owned and operated by the Vares

council. Raw water supply the Project mine is from a dedicated

utility source provided by the local water company JKP d.o.o. Vares

(JKP).

Underground services

Services namely service water, potable water, compressed air,

and dewatering are reticulated underground via adequately sized and

rated polyethylene piping routed up or down decline ramps or up or

down service holes to or from the production levels.

Underground power distribution

The electrical power to underground mining consumers via the

underground reticulation is supplied at 10 kV and stepped down via

secondary distribution transformers which feed 1 kV underground

power distribution centers.

Maximum power demand for the underground mine operation at site

supply voltage to support full development and production

activities is required to appropriately size and select the

electrical infrastructure for the underground mine. A provision of

emergency power has been made for the critical underground

loads.

Appendix

2023 RUPICE MRE UPDATE

The updated Indicated and Inferred Mineral Resource estimate was

prepared by AMC as set out in Table 1. The effective date is 21

July 2023.

Table 1 - Rupice updated 2023 MRE by Classification - Total

(using AgEq cut-off of 50 g/t)

Rupice Mineral Resource estimate, 21 July 2023

Deposit(s) Resource Tonnes Grades Contained metal

Classification (Mt)

------------ ---------------- ------- ------------------------------------------------- --------------------------------------------

Domains Ag Zn Pb Au Cu Sb BaSO(4) Ag Zn Pb Au Cu Sb BaSO(4)

------------ ---------------- -------

g/t % % g/t % % % Moz Kt Kt Koz Kt kt Kt

------------ --------- ---------------- ------- ---- ----- ----- ----- ----- -------- ------ ---- ---- --- --- --------

Rupice + All Indicated 18.3 168 4.6 2.9 1.3 0.4 0.2 30 98.6 844 535 742 81 36 5,426

RNW Inferred 2.8 75 2.4 1.6 0.5 0.2 0.1 13 6.8 69 46 47 7 4 353

--------------- ------- ---- ----- ----- ----- ----- -------- ------ ---- ---- --- --- --------

Total Indicated + Inferred 21.1 156 4.3 2.8 1.2 0.4 0.2 27 105.4 913 581 789 88 39 5,779

--------- ----------------------------- ------- ---- ----- ----- ----- ----- -------- ------ ---- ---- --- --- --------

Table 2 - Rupice updated MRE by Classification and Deposit

(using AgEq cut-off of 50 g/t)

Rupice Mineral Resource estimates, 21 July 2023

Deposit(s) Resource Tonnes Grades Contained metal

Classification (Mt)

------------ ---------------- ------- -------------------------------------------------------- -------------------------------------------------------

Domains Ag Zn Pb Au Cu Sb BaSO(4) Ag Zn Pb Au Cu Sb BaSO(4)

------------ ---------------- -------

g/t % % g/t % % % Moz Kt Kt Koz Kt kt Kt

------------ --------- ---------------- ------- ------ ------ ------ ------ ------ -------- ------- ------ ------ ----- ----- --------

Rupice All Indicated 11.0 169 4.0 2.6 1.4 0.4 0.2 27 60.1 443 285 503 46 25 3,020

Inferred 1.7 52 1.1 0.8 0.3 0.2 0.1 9 2.9 19 13 17 3 2 154

Total 12.8 153 3.6 2.3 1.3 0.4 0.2 25 62.9 462 298 520 48 27 3,174

--------------------------------------- ------- ------ ------ ------ ------ ------ -------- ------- ------ ------ ----- ----- --------

RNW All Indicated 7.2 166 5.6 3.5 1.0 0.5 0.2 33 38.5 401 250 239 35 11 2,406

Inferred 1.1 111 4.6 3.0 0.9 0.4 0.1 18 3.9 50 32 30 4 1 199

Total 8.3 159 5.4 3.4 1.0 0.5 0.2 31 42.5 452 283 269 39 13 2,605

--------------------------------------- ------- ------ ------ ------ ------ ------ -------- ------- ------ ------ ----- ----- --------

Total Indicated 18.3 168 4.6 2.9 1.3 0.4 0.2 30 98.6 844 535 742 81 36 5,426

Inferred 2.8 75 2.4 1.6 0.5 0.2 0.1 13 6.8 69 46 47 7 4 353

--------------------------------------- ------- ------ ------ ------ ------ ------ -------- ------- ------ ------ ----- ----- --------

Table 3 - Rupice updated MRE by Classification, and Deposit by

Domain (using AgEq cut-off of 50 g/t)

Rupice Mineral Resource estimates, 21 July 2023

Deposit(s) Resource Tonnes Grades Contained metal

Classification (Mt)

------------ ---------------- ------- --------------------------------------------------------- -------------------------------------------------------

Domains Ag Zn Pb Au Cu Sb BaSO(4) Ag Zn Pb Au Cu Sb BaSO(4)

------------ ---------------- -------

g/t % % g/t % % % Moz Kt Kt Koz Kt kt Kt

------------ --------- ---------------- ------- ------ ------ ------ ------ ------- -------- ------- ------ ------ ----- ----- --------

Rupice Upper Indicated 0.4 55 1.0 1.0 0.4 0.2 0.1 6 0.7 4 4 5 1 1 21

Inferred 0.2 74 1.3 1.0 0.3 0.2 0.2 10 0.6 3 2 2 0.5 0 24

Total 0.6 62 1.1 1.0 0.3 0.2 0.1 7 1.3 7 6 7 1 1 46

--------------------------------------- ------- ------ ------ ------ ------ ------- -------- ------- ------ ------ ----- ----- --------

Rupice Main Indicated 10.2 180 4.3 2.7 1.5 0.4 0.2 29 58.8 436 278 495 44 23 2,984

Inferred 1.0 50 1.1 0.7 0.3 0.1 0.1 11 1.7 12 8 12 2 1 112

Total 11.2 168 4.0 2.6 1.4 0.4 0.2 28 60.5 448 286 506 46 25 3,097

--------------------------------------- ------- ------ ------ ------ ------ ------- -------- ------- ------ ------ ----- ----- --------

Rupice Lower Indicated 0.5 35 0.7 0.5 0.2 0.1 0.1 3 0.6 3 2 4 1 1 14

Inferred 0.4 44 0.9 0.8 0.2 0.1 0.1 4 0.6 4 3 3 0.4 0 17

Total 0.9 39 0.8 0.6 0.2 0.1 0.1 3 1.2 7 6 7 1 1 31

--------------------------------------- ------- ------ ------ ------ ------ ------- -------- ------- ------ ------ ----- ----- --------

RNW Upper Indicated 1.3 75 1.5 0.8 0.2 0.1 0.2 13 3.1 19 11 9 1 3 161

Inferred 0.2 65 1.0 1.4 0.2 0.2 0.1 10 0.5 2 3 2 0.4 0.3 23

Total 1.5 74 1.4 0.9 0.2 0.1 0.2 12 3.6 21 14 11 2 3 184

--------------------------------------- ------- ------ ------ ------ ------ ------- -------- ------- ------ ------ ----- ----- --------

RNW Main Indicated 4.5 214 7.4 4.7 1.4 0.6 0.20.1 47 30.8 332 211 199 26 7 2,113

Inferred 0.4 145 7.9 4.9 1.5 0.5 0.1 36 1.9 33 20 20 2 0.5 148

Total 4.9 209 7.5 4.7 1.4 0.6 46 32.7 365 231 219 29 7 2,261

--------------------------------------- ------- ------ ------ ------ ------ ------- -------- ------- ------ ------ ----- ----- --------

RNW Lower Indicated 1.5 98 3.4 1.9 0.7 0.5 0.1 9 4.7 55 29 31 7 2 2,406

Inferred 0.4 105 3.4 2.1 0.5 0.4 0.1 6 1.5 15 9 8 1.6 1 199

Total 1.9 100 3.4 2.0 0.6 0.4 0.1 8 6.2 66 38 39 9 2 2,605

--------------------------------------- ------- ------ ------ ------ ------ ------- -------- ------- ------ ------ ----- ----- --------

Indicated +

Total Inferred 21.1 156 4.3 2.8 1.2 0.4 0.2 27 105.4 913 581 789 88 39 5,779

--------- ----------------------------- ------- ------ ------ ------ ------ ------- -------- ------- ------ ------ ----- ----- --------

Notes:

-- The Mineral Resource estimate has been reported in accordance

with the requirements of ASX Listing Rule 5.8 and the JORC

Code.

-- A cut-off grade of 50 g/t silver equivalent has been applied.

-- Silver equivalent (AgEq) -was calculated using conversion

factors of 31.1 for Zn, 24.88 for Pb, 80.0 for Au, 1.87 for BaSO(4)

, 80.87 for Cu, 80.87 for Sb, and recoveries of 90% for all

elements. Metal prices used were US$2,500/t for Zn, US$2,000/t for

Pb, US$150/t for BaSO(4) , US$2,000/oz for Au, US$25/oz for Ag,

US$6,500/t for Sb and US$6,500 for Cu.

-- The applied formula was: AgEq = Ag(g/t) x 90% + 31.1 x Zn(%)

x 90% + 24.88 x Pb(%) * 90% + 1.87 x BaSO(4) % x 90% + 80 x Au(g/t)

x 90% + 80.87 x Sb(%) x 90% + 80.87 x Cu(%) x 90%

-- It is the opinion of Adriatic Metals and the Competent

Persons that all elements and products included in the metal

equivalent formula have a reasonable potential to be recovered and

sold.

-- Metallurgical recoveries of 90% have been applied in the

metal equivalent formula based on recent and ongoing test work

results.

-- A bulk density (BD) was calculated for each model cell based

on its domain, using regression formulas. For the Main zone: BD =

2.66612 + BaSO(4) x 0.01832 + Pb x 0.03655 - Zn x 0.02206 + Cu x

0.09279 for the barite high-grade domain, BD = 2.72748 + BaSO(4) x

0.02116 + Pb * 0.04472 + Zn x 0.01643 - Cu x 0.08299 for the barite

low-grade domain; and for the NW zone: BD = 2.92581 + BaSO(4) x

0.01509 + Pb x 0.04377 - Zn x 0.02123 + Cu x 0.10089 for the barite

high-grade domain, BD = 2.74383 + BaSO(4) x 0.01731 + Pb x 0.04573

+ Zn x 0.02023 - Cu x 0.06041 for the barite low-grade-domain (the

barite domains were interpreted using 30% BaSO(4) cut-off).

-- Rows and columns may not add up due to rounding.

APPIX 1: RUPICE MRE JORC TABLES

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

----------------------------------------------------------------------------------------------------------------------

Criteria JORC Code Explanation Commentary

-------------------------------------- --------------------------------------

Sampling techniques Nature and quality of sampling (e.g. Drill core samples were collected from

cut channels, random chips, or half cut PQ3 and HQ3 diameter core,

specific specialised where the core

industry standard measurement tools was sawn exactly in half along a

appropriate to the minerals under pre-defined cutting line.

investigation, such The half core samples, typically

as down hole gamma sondes, or handheld weighing between 4-12kg, were placed

XRF instruments, etc). These examples into labelled and tagged

should not be sample bags prior to dispatch to the

taken as limiting the broad meaning of SGS Ankara laboratory in Turkey.

sampling. Sample intervals were determined by

the geologist, routinely at nominal 1m

intervals unless

selectively sampled on narrower

intervals where geological boundaries

exist to a minimum length

of 0.2 m. A maximum sample size of 1.2

m is used when sampling to geological

contacts.

Portable XRF is used to confirm

sulphides and barite quantities in

core. pXRF results are

used for indicative purposes only and

not as final assay.

-------------------------------------- --------------------------------------

Include reference to measures taken to Sample intervals were selected by the

ensure sample representivity and the logging geologist based on geological

appropriate calibration criteria or using

of any measurement tools or systems a nominal 1m sample length in

used. homogenous massive sulphide ore. A

minimum sample length of

0.2 m is employed where necessary.

Sampling is based on visually

mineralized intervals, with

a calibrated portable XRF device used

only as a guide. pXRF is calibrated

using standards

daily when in use.

-------------------------------------- --------------------------------------

Aspects of the determination of For drill hole analyses, diamond

mineralisation that are Material to drilling was used to obtain 4 to 12kg

the Public Report. In samples, crushed, pulverized

cases where 'industry standard' work and split for Fire Assay (30g charge),

has been done this would be relatively ICP-AES and ICP-MS, AAS, XRF and

simple (e.g., 4-acid digest using

'reverse circulation drilling was used external laboratories and certified

to obtain 1 m samples from which 3 kg laboratory methods.

was pulverised Prior to October 2022, samples were

to produce a 30 g charge for fire dispatched by dedicated road transport

assay'). In other cases, more to ALS Bor in Serbia

explanation may be required, for sample prep, splitting and

such as where there is coarse gold analysis across several ALS labs

that has inherent sampling problems. (Ireland and Romania).

Unusual commodities From October 2022 core samples were

or mineralisation types (e.g. sent to SGS Ankara, Turkey by truck

submarine nodules) may warrant for sample preparation

disclosure of detailed information. (SGS Code PRP89), gold analysis by

30-gram fire assay with AA finish (SGS

code FAA303), base

and precious metal as well as

multi-element analyses using a 4-Acid

Digest with ICP-AES finish

(code ICM40B). AAS was used for

over-detection limit analysis of base

metals.

Barite was assayed using lithium

borate fusion prior to acid

dissolution and ICP-MS analysis

(SGS code ICP95A). Overlimit Barium

(>10%) results were analysed using

portable pXRF (SGS

code pXRF73C27) and the results above

detection limit (50%) sent to SGS

Lakefield, Canada

by air freight for whole-rock XRF

analysis (SGS Code GC_XR76V).

-------------------------------------- --------------------------------------

Drilling techniques Drill type (e.g. core, reverse All drill holes were drilled using PQ3

circulation, open-hole hammer, rotary and HQ3 diameter core.

air blast, auger, Bangka, All drill holes were drilled by

sonic, etc) and details (e.g. core drilling contractor Drillex BH d.o.o.,

diameter, triple or standard tube, a division of Drillex

depth of diamond tails, International.

face-sampling bit or other type, PQ3 and HQ3 core was held in a core

whether core is oriented and if so, by barrel by a stainless steel "split"

what method, etc). inner tube. The use

of the inner tube ensured that all

core maintained its orientation prior

to removal into the

core trays. Drill core was stored in

suitable core boxes and stacked on the

premises of the

secure exploration facility in Vares.

All drill holes were surveyed at 9 m

and every 30 m thereafter by a Reflex

"Ezy-Track" digital

down-hole survey tool to end of 2022.

As of 2023, all holes have been

surveyed using the Reflex

'Sprint IQ' and 'Omni' on the fly

north seeking non-magnetic gyroscopic

tools at 5 m intervals

in and 10 m out of holes. No

significant deviation or drilling

problems have been identified.

Representatives from Reflex have been

to drill rigs to calibrate, check and

train on correct

usage of tools.

-------------------------------------- --------------------------------------

Drill sample recovery Method of recording and assessing core All core was geotechnically logged to

and chip sample recoveries and results verify drillers blocks, record run

assessed. length, recovered

length, core recovery (%) and RQD.

There is no observed relationship

between sample recovery and grade, and

no significant loss

of core. No sample bias has been

identified. Core recoveries are

generally >90%

-------------------------------------- --------------------------------------

Measures taken to maximise sample

recovery and ensure representative

nature of the samples.

-------------------------------------- --------------------------------------

Whether a relationship exists between

sample recovery and grade and whether

sample bias may

have occurred due to preferential

loss/gain of fine/coarse material.

-------------------------------------- --------------------------------------

Logging Whether core and chip samples have Diamond drill core samples have been

been geologically and geotechnically geologically and geotechnically logged

logged to a level to a level of

of detail to support appropriate detail to support appropriate Mineral

Mineral Resource estimation, mining Resource estimation, mining studies

studies and metallurgical and metallurgical

studies. studies. Not all drill holes

penetrated the massive sulphide

mineralization, but all were

used to guide the geological

interpretations supporting the Mineral

Resource estimates.

-------------------------------------- --------------------------------------

Whether logging is qualitative or All core is photographed. Core logging

quantitative in nature. Core (or is both qualitative and quantitative.

costean, channel, etc) Logging records

photography. lithology, alteration, structures,

veining, sulphide minerals and

percentages.

-------------------------------------- --------------------------------------

The total length and percentage of the 100% of drill core is logged.

relevant intersections logged.

-------------------------------------- --------------------------------------

Sub-sampling techniques and sample If core, whether cut or sawn and Drill core was cut in half using an

preparation whether quarter, half or all core Almonte automatic diamond core saw.

taken. Nominally 1 in 30

samples were cut in quarters, and both

halves analysed (for purposes of field

duplicates).

-------------------------------------- --------------------------------------

If non-core, whether riffled, tube Not applicable, as all samples are

sampled, rotary split, etc and whether core.

sampled wet or

dry.

-------------------------------------- --------------------------------------

For all sample types, the nature, Collection of around 4-12kg of HQ and

quality, and appropriateness of the PQ half core material with subsequent

sample preparation pulverisation

technique. of the total charge provided an

appropriate and representative sample

for analysis. Generally

4-6kg for HQ core and 6-12kg for PQ.

Prior to October 2022, sample

preparation was undertaken at the ALS

laboratory in Bor, Serbia

to industry best practice.

From October 2022, sample preparation

was undertaken at the SGS Laboratory

in Ankara, Turkey

to industry best practice.

-------------------------------------- --------------------------------------

Quality control procedures adopted for Whole rock blanks and certified

all sub-sampling stages to maximise standards (1 in 15) were introduced

representivity to the sample stream

of samples. as a QAQC check on laboratory

processes. Industry best practice was

adopted by ALS and SGS

for laboratory sub-sampling and the

avoidance of any cross contamination.

ALS + SGS inserted

internal controls and cleaned all

sampling equipment with a barren

quartz rock every 20 samples.

All sample preparation stations and

equipment were compressed air cleaned

after every sample.

A QAQC inspection of ALS (Bor) and SGS

(Ankara) facilities was completed in

October 2022 by

Adriatic Metals (S. Smolonogov) with

practices found to be in line with

industry best practice.

-------------------------------------- --------------------------------------

Measures taken to ensure that the The half-core sampling is considered a

sampling is representative of the reasonable representation of the

in-situ material collected, in-situ material.

including for instance results for Nominally 1 in 30 samples were cut in

field duplicate/second-half sampling. quarters, and both halves analysed

(for purposes of

field duplicates). All field

duplicate, coarse duplicate and pulp

duplicates are reviewed

and compared. Standards and Blanks are

investigated if over 2SD (2 Standard

Deviations) from

certified mean and re-assay initiated

if over 3SD or as required when over

2SD to validate

materials either side of poorly

performing blanks or standards. QAQC

outcomes are checked

on assay receipt by Adriatic Metals

and before acceptance into the

Database. A dedicated Data

Geologist with support from

consultants gDAT monitor all received

QAQC data as it arrives.

-------------------------------------- --------------------------------------

Whether sample sizes are appropriate Sample size of around 4-12kg is

to the grain size of the material appropriate and found to reasonably

being sampled. represent the material

being tested. There is acceptable

repeatability of multiple economic

elements. 4-6kg for HQ

and 6-12kg for PQ.

-------------------------------------- --------------------------------------

Quality of assay data and laboratory The nature, quality and Prior to October 2022, primary

tests appropriateness of the assaying and analysis was completed through ALS

laboratory procedures used and Laboratories. With Sample

whether the technique is considered preparation as ALS Bor, Serbia with

partial or total. splitting and sending pulps to

Loughrea, Ireland and Rosa

Montana, Romania.

From October 2022, primary sample

preparation and analysis was completed

by SGS Laboratory

in Ankara, Turkey

All facilities are industry best

practice and ISO certified. Multi

elements were assayed by

an ICP-AES technique following a

four-acid digest. Gold was determined

using a fire assay

on nominal 30g charges. Barite was

determined from a lithium meta-borate

fusion followed by

dissolution and ICP-AES analysis.

Total carbon and sulphur were

determined by a Leco analyser.

All techniques were appropriate for

the elements being determined. Use of

a 4-Acid digest

is a near-total digestion of all

minerals present.

Additional pXRF and whole rock XRF

analysis is required to determine

accurate concentrations

of barium as part of reported assays.

Whole rock XRF analysis is completed

at Lakefield Canada.

Initiation of a gravimetric finish was

initiated at start of Q2 2023. Gold

results >3.00 g/t

are re-assayed by fire assay with

gravimetric finish at SGS Ankara

laboratory.

-------------------------------------- --------------------------------------

For geophysical tools, spectrometers, There was no reliance on determination

handheld XRF instruments, etc, the of analysis by geophysical tools. All

parameters used analyses as reported

in determining the analysis including and used in any calculations are by

instrument make and model, reading ISO certified laboratories, (ALS -

times, calibrations Bor, Loughrea, Rosa

factors applied and their derivation, Montana; SGS Ankara), using

etc. calibrated, industry standard and

recognized methods, QAQC and

equipment.

A Hitachi X-Met 8000 hand-held pXRF

analyser is used to rapidly define

metal and barite abundance

during logging, field mapping and

sampling. Results are not used in

resource estimates or

publicly reported.

-------------------------------------- --------------------------------------

Nature of quality control procedures Certified Reference Materials

adopted (e.g. standards, blanks, ("CRM's"), certified blanks, quarter

duplicates, external core replicates were used

laboratory checks) and whether and considered to be appropriate for

acceptable levels of accuracy (i.e. the elements being analysed. CRM's,

lack of bias) and precision blanks, and replicates

have been established. were added at a rate better than 1 in

15. All results reported by SGS on the

CRMs and blanks

were within 3 standard deviations

(3SD). Where deviations greater than

2SD where noted, investigations

were completed and where necessary

samples above and below queried

Standards and Blanks were

re-assayed. To date returned results

are considered to be representative of

material sampled.

A program of 5% of assay pulps are

submitted for Umpire lab re-assay. The

program is continuous

and ongoing as part of QAQC controls

in addition to measures already in

place.

ACME Laboratory (Bureau Veritas) in

Ankara, Turkey is used as the current

independent Umpire

Laboratory replicating 5% of pulp

duplicate results for QAQC. ACME

commenced QAQC work on

exploration drilling samples as of

2023. Prior to 2023, the SGS Bor,

Serbia assay laboratory

has been used as the independent

Umpire laboratory for primary samples

returned from ALS Bor,

Serbia. ALS previously completed

primary analysis using multiple

facilities with sample preparation

at ALS Bor, Serbia; base metals

analysis at ALS Loughrea Ireland; gold

at ALS Rosa Montana

Romania.

-------------------------------------- --------------------------------------

Verification of sampling and assaying The verification of significant Significant mineralization is reviewed

intersections by either independent or internally by multiple Senior

alternative company geological staff, the

personnel. Vares Project Exploration Manager, and

Head of Exploration. Significant

intercepts are visually

verified daily as core is brought in

for logging, included in summary logs,

and then cross-checked

during detailed logging. Tenor and

confirmation of mineralization and

barite content is checked

by portable XRF (Hitachi X-Met 8000).

Mineralized intervals are regularly

viewed and verified by geosciences

qualified and certified

investors and analysts. Recent drill

core is presented in fully marked-out

core boxes and

with full assay data provided for

correlation with drilled intercepts.

Independent relogging of select

mineralized and non-mineralized drill

core has been completed

by multiple consultants involved in

technical studies including Elizabeth

Thompson (Structural

Consultant - Transition Elements), Joe

Crummy (ARD Consultant - JC

Consulting), Joe Burke

(Geotechnical Consultant - Avoca

Geotechnical) and others.

-------------------------------------- --------------------------------------

The use of twinned holes. Several twinned holes have been

completed, with separation between

holes reduced to within

15 m.

Several cross-holes have also been

drilled from adjacent drill platforms,

passing through

the trace of previous holes and at

near right angle cutting previously

intercepted mineralization.

Confirming position, grade, and

thickness.

In general, holes completed are part

of tight 'drill fans' with separation

of holes between

fans of 25 m to 30 m with respect to

targeted ore zones. Separation

distances are <25 m between

holes closer to surface and the

collars of fan holes drilled from the

same drill platform.

In 2023 in areas referred to as the

Rupice Northwest Western Zone, and

Rupice Northwest Lower

Zone, hole spacings have been reduced

to nominally <20 m between mineralized

intercepts. This

is due to the increased folding and

faulting seen in these areas requiring

closer spaced drilling

to resolve geology.

-------------------------------------- --------------------------------------

Documentation of primary data, data Data are stored in a Cloud Server with

entry procedures, data verification, server back-ups at various locations

data storage (physical including Vares,

and electronic) protocols. Bosnia & Herzegovina and Cheltenham,

UK. The data and databases are managed

by consultants

gDat Data Solutions in an acQuire

database. The acQuire database is

regularly backed-up. There

is a dedicated Data Geologist and a

Junior Data Geologist within

Exploration managing and

ensuring the QAQC of all daily

geological inputs and outputs from the

database and various

software (downhole survey, surface

survey, audits, drilling data,

logging, sampling, sample

dispatch, assaying and assay QAQC).

gDat interfaces daily with the site

Data Geologists.

-------------------------------------- --------------------------------------

Discuss any adjustment to assay data. No adjustments were necessary.

-------------------------------------- --------------------------------------

Location of data points Accuracy and quality of surveys used Sampling sites were surveyed using

to locate drill holes (collar and Total Station to better than 0.05 m

down-hole surveys), accuracy in the local

trenches, mine workings and other BiH coordinate system.

locations used in Mineral Resource A Reflex TN4 north seeking, gyroscopic

estimation. rig alignment tool was used as of 2023

for precision

alignment of holes at the collar. The

TN14 is mounted on the rod string with

preset mast dip

and hole azimuth referenced to grid

north converted from UTM. Mast and rig

are moved till

TN14 reads that the rod string is

aligned to set dip and direction. The

TN14 can also be used

in place of the Total Station or as a

check of the Total Station collar

set-up survey accuracy.

-------------------------------------- --------------------------------------

Specification of the grid system used. The grid system used MGI 1901 /

Balkans Zone 6.

-------------------------------------- --------------------------------------

Quality and adequacy of topographic The topographic surface of the

control. immediate area was generated from a

LiDAR survey to an accuracy

of approximately 0.05 m. It is

considered sufficiently accurate for

the Company's current

activities. All drill collars have

been compared to the LiDAR surface and

physically validated

where discrepancies in elevation or

position where noted. Validation has

been periodically

required in mountainous terrain where

holes post-date LiDAR and earthworks

have been completed

to establish drill pads.

-------------------------------------- --------------------------------------

Data spacing and distribution Data spacing for reporting of Drill hole spacing does not exceed 50

Exploration Results. m which is considered acceptable for

reporting exploration

results. The nominal drill spacing is

on 40 m spaced sections. The primary

method of drilling

is to complete holes from a single

drill platform in mountainous terrain.

Holes are drilled

as part of a 'fan' of holes. Design of

holes aims to achieve a nominal 25 m

to 30 m separation

between mineralized zones to achieve

either an Inferred or Indicated level

of exploration

confidence.

-------------------------------------- --------------------------------------

Whether the data spacing and Drill hole spacing is deemed

distribution is sufficient to sufficient to establish the degree of

establish the degree of geological geological and grade continuity

and grade continuity appropriate for appropriate for the Mineral Resource

the Mineral Resource and Ore Reserve classification to be applied. The data

estimation procedure(s) spacing is suitable

and classifications applied. for a stratabound, continuous style of

polymetallic mineralization with

minimal structural

disturbance or remobilisation.

Where structural complexity is noted

(RNW Western and Lower Zones), drill

hole spacing is

reduced to <20 m.

-------------------------------------- --------------------------------------

Whether sample compositing has been Sample compositing was not applied.

applied. Currently reported results are on a

nominal 1m spacing

unless samples have been character

sampled or extended to visual

contacts. Minimum sample

size is 0.2 m and maximum is 1.2 m

unless there has been low sample

recovery.

-------------------------------------- --------------------------------------

Orientation of data in relation to Whether the orientation of sampling Drill holes have been drilled at dips

geological structure achieves unbiased sampling of possible of between -45 to -90deg from surface.

structures and The mineralized

the extent to which this is known, body is generally shallow dipping to

considering the deposit type. the NE and plunging to the NW at

angles of 30 to 40 degrees.

Current drilling intersects

mineralization at generally a high

oblique angle.

New drilling in the RNW Lower Zone has

seen mineralization approach

subvertical angles. Drilling

in these areas has been at right

angles to steep mineralization and

from 45 to 60 degrees

allowing multiple holes to transect

steeper mineralization over a vertical

elevation spread

of holes.

-------------------------------------- --------------------------------------

If the relationship between the It is not considered that the drilling

drilling orientation and the orientation has introduced a sampling

orientation of key mineralised bias, as the

structures is considered to have drilling is considered to be

introduced a sampling bias, this orthogonal to the stratabound

should be assessed and reported mineralization, or close to it.

if material.

-------------------------------------- --------------------------------------

Sample security The measures taken to ensure sample Chain of Custody of digital data is

security. managed by the Company. Physical

material was stored on

site and, when necessary, delivered to

the assay laboratory. Thereafter

laboratory samples

were controlled by the nominated

laboratory. All sample collection was

controlled by digital

sample control file(s) and hard-copy

ticket books.

Transfer of samples to laboratories is

by a dedicated enclosed commercial

truck. No other

freight is included with shipments.

Weigh-bills are used as are multiple

customs declarations.

Dispatched samples have sample tickets

included, are referenced to a

pre-dispatch sample submission

sheet, and are cross-checked on

receipt at laboratory. To date no

discrepancies, sample loss

or tampering with samples has been

recorded.

-------------------------------------- --------------------------------------

Audits or reviews The results of any audits or reviews Laboratory reviews of SGS Ankara,

of sampling techniques and data. Turkey; ALS Bor Serbia; SGS Bor,

Serbia; ACME (Bureau Veritas)

Ankara, Turkey were completed by

Sergei Smolonogov (MAIG, RPGEO), Head

of Exploration of Adriatic

Metals, in October 2022 and SGS + ACME

Lab in Ankara in February 2023. There

were no material

issues found. Items for laboratory

improvement were noted but were not

considered material

to sample QAQC outcomes.

As a result of Adriatic Metals audit,

SGS Ankara has renovated and installed

vacuum dust extraction

enclosed workstations (crushers,

pulverisers, splitters) to reduce

sample contamination risks

in sample preparation. Changes

effective as of February 2023.

-------------------------------------- --------------------------------------

Section 2: Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section)

----------------------------------------------------------------------------------------------------------------------

Criteria JORC Code explanation Commentary

-------------------------------------------------------------- --------------------------

Mineral tenement and land Type, reference name/number, location and ownership including The Rupice deposit is

tenure status agreements or material issues located within the

with third parties such as joint ventures, partnerships, Company's 100% owned

overriding royalties, native title Concession, No.

interests, historical sites, wilderness or national park and 04-18-21389-1/13,

environmental settings. located 13km west of Vares

in Bosnia. There are no

known material issues with

any third-party

other than normal

royalties due to the

State.

-------------------------------------------------------------- --------------------------

The security of the tenure held at the time of reporting along The Concession is in good

with any known impediments standing with the

to obtaining a licence to operate in the area. governing authority and

there is no known

impediment

to the Concession

remaining in force until

2038 (25 years), subject

to meeting all necessary

reporting requirements.

-------------------------------------------------------------- --------------------------

Exploration done by other Acknowledgment and appraisal of exploration by other parties. Modern exploration

parties commenced with the work of

Energoinvest in the late

1960s. During 1968-1969

underground development of

455 m of drives and cross

cuts were made, and 11

surface trenches

dug for a total length of

93.5 m. Between 1980 and

1989, 49 holes were

drilled for a total

of 5,690.8 m. Sample

material from all these

programs was routinely

analysed for lead, zinc,

and barite, and on

occasion silver and gold.

The deposit was the

subject of several reserve

estimates in the 1980s.

This work is documented in

many reports which are

certified by those

geoscientists and

Institutes that undertook

the work. The work is

considered of a standard

equal to that found within

today's exploration

industry.

-------------------------------------------------------------- --------------------------

Geology Deposit type, geological setting and style of mineralisation. The host rocks at Rupice

comprise Middle Triassic

limestone, dolostone,

calcareous and dolomitic

marl, and a range of

mostly fine-grained

siliciclastic rocks

including cherty mudstone,

mudstone,

siltstone, and

fine-grained sandstone.

The main mineralized

horizon is a brecciated

dolomitic

unit that dips at around

50(o) to the northeast and

has been preferentially

mineralized with

base, precious and

transitional metals. The

Triassic and Jurassic

sequences have been

deformed

by early-stage ductile

shearing and late-stage

brittle faulting.

The Rupice polymetallic

mineralization consists of

sphalerite, galena, barite

and chalcopyrite

with gold, silver,

tetrahedrite, boulangerite

and bournonite, with

pyrite. Most of the

high-grade

mineralization is hosted

within a brecciated

dolomitic unit, which is

interpreted to be

cross-cut

by northwest striking,

westerly dipping syn-post

mineral faulting.

Thickening of the central

portion of the deposit

occurs in an area of

structural complexity.

Mineralized widths of up

to 65 m true thickness are

seen in the central

portion of the deposit.

To date, the massive

sulphide mineralization at

Rupice has a defined

strike length of 650

m, with an average

true-width thickness of

around 20 m. However,

recent drilling northwest

of Rupice has intercepted

a massive sulphide body

referred to as Rupice

Northwest (RNW). RNW

is not connected to Rupice

mineralization. RNW is at

a stratigraphically lower

level (footwall

of Lower GYD unit) than

Rupice (hanging-wall of

Lower GYD unit) and is

interpreted to overlap

but not connect with

Rupice through the area

referred to as the 'Gap'.

RNW currently has a strike

extent of approximately

250 m with mineralization

remaining open

in most directions. The

RNW mineralization appears

mostly not impacted by

deformation at the

scale of drilling and

compared to Rupice is a

continuous tabular

stratabound mineralized

body.

Multiple mineralized

intercepts at RNW have

true thicknesses of over

40 m along the centre

axis of mineralization.

Mineralization away from

the central NW-SE strike

axis tapers away

at the margins to <1.00 m

true thickness. This can

be 60 m to 80 m away and

either side from

the strike axis centre

line. The up-dip extent of

RNW has not yet been

closed-off, therefore

a true SW-NE width of

mineralization cannot be

stated. The strike extent

is similarly open.

To the NW, the RNW

mineralization appears to

be thickening and widening

on the last sections

drilled. To the SE and

closest to Rupice,

mineralization is still

continuous, and has a

thickness

of up to 20 m. On the

sections drilled to date,

RNW is only closed on the

NE side where it

rapidly tapers out with

the absence of the

overlying GYD unit.

Rupice NW mineralization

is strongly associated

with barite occurring as a

matrix to sulphides.

Barite can be up 80% of

mineralized zones. Galena,

sphalerite, pyrite and

chalcopyrite are

the most visible and

identifiable sulphides

during logging. The

footwall zone below

massive

and semi-massive sulphides

is pervasively

silica-sericite altered

with fine disseminated

sulphides

throughout and crosscut by

base metal stringer zones

and mineralized faults /

shears. This

alteration zone can extend

20 m to 30 m below massive

and semi-massive

sulphides. Overall,

the footwall zone appears

enriched in zinc.

On the hanging wall of

Rupice NW there is a

pyrite rich, low barite,

high base metal content

horizon of mineralization

referred to as the Upper

Zone. It is approximately

90 m to 100 m

vertically above Rupice

NW. It appears to be a

mineralized zone occurring

as matrix within

a dolomite breccia. The

mineralized Upper Zone

marks the transition from

Jurassic into mineralized

Triassic sediments and

generally occurs at the

base of a major thrust

zone and what is referred

to as the Upper GYD unit.

-------------------------------------------------------------- --------------------------

Drill hole information A summary of all information material to the understanding For the 2023 MRE (Rupice

of the exploration results including and RNW), a total of 287

a tabulation of the following information for all Material diamond drill holes for a

drill holes: total of 76,935

* easting and northing of the drill hole collar m define the current

limits of the known

mineralization. Up to

* elevation or RL (Reduced Level - elevation above sea mid-2022, the deposit was

level in metres) of the drill hole collar drilled

and sampled using diamond

drill holes on a nominal

* dip and azimuth of the hole 20 m by 20 m spacing. As

of mid-2022 to

May 2023, the drill hole

* downhole length and interception depth spacing was widened to a

40 m x 30 m spacing across

RNW reflecting

* hole length. the robust continuity of

the stratabound

mineralization along and

If the exclusion of this information is justified on the across strike. Drilling

basis that the information is not defined a combined Rupice

Material and this exclusion does not detract from the and RNW mineralized system

understanding of the report, the Competent having a strike length of

Person should clearly explain why this is the case. >900 m and

an across-strike width of

>350 m.

The Rupice portion of the

2023 Mineral Resource

estimate includes a total

of 207 diamond drill

holes comprising holes

drilled prior to Adriatic

Metals (49), and the

Company's drilling

programs

in 2017, 2018, 2019, 2020,

2021, and 2022 for a total

of 51,228 m to define the

current limits

of known Rupice

mineralization. The

deposit was drilled and

sampled using diamond

drill holes

on a nominal 20 m by 20 m

spacing up to the end of

2022. Drilling defined the

Rupice deposit

to have a strike length of

>600 m and an

across-strike width of

>350 m.

The RNW portion of the

2023 MRE includes a total

of 80 diamond drill holes

from the Company's

drilling programs in 2021,

2022, and 2023 for a total

of 25,708 m to define the

current limits

of the known RNW

mineralization. Up to

Mid-2022, the deposit was

drilled and sampled using

diamond drill holes on a

nominal spacing of 40 m by

20 m. From mid-2022 to end

of May 2023

the drill hole spacing was

widened to a 40 m by 30 m

spacing. The widening of

the drill spacing

was in response to the RNW

deposit being spatially

continuous over its >300 m

strike length

and having a >260 m

across-strike width.

Since the last resource

estimation in September

2020, the drilling program

added 120 new drill

holes and 38,800 m.

No drilling details or

assays are presented in

this release as all have

been publicly reported

to date. The last drill

hole completed and

included in the 2023 July

Resource is BR-29A-23.

-------------------------------------------------------------- --------------------------

Data aggregation methods In reporting Exploration Results, weighting averaging No data aggregation

techniques, maximum and/or minimum methods were applied.

grade truncations (e.g., cutting of high grades) and cut-off Reported Mineral Resource

grades are usually Material and Estimates are calculated

should be stated. by applying a lower

cut-off grade of 50

g/t AgEq (see notes below

Tables 1 to 3 in body of

announcement for

assumptions for AgEq

calculations).

There is no individual

element high-grade

capping.

Grade recoveries of 90%

and commodity prices as

used for the Rupice MRE

from September 2020

were applied.

Metallurgical test work

has been completed on the

Rupice deposit and test

work

is in progress for the RNW

deposit.

Given the style of

mineralization,

mineralogy, and grade of

mineralization at RNW is

similar

to Rupice, the same

metallurgical assumptions

are applied till results

are returned from RNW

test work.

A maximum internal

dilution of 5 m is allowed

within mineralized

wireframes. A top-cut was

not applied.

Previously reported

significant intercepts

were reported as weighted

averages.

-------------------------------------------------------------- --------------------------

Where aggregate intercepts incorporate short lengths of Where significant assays

high-grade results and longer lengths have been previously

of low-grade results, the procedure used for such aggregation reported, short intervals

should be stated and some typical of significant high-grade