Wabash Partners with University of Delaware to Advance Solar Solutions in Commercial Transportation

10 October 2024 - 9:55PM

Wabash (NYSE: WNC), the visionary leader of connected solutions for

the transportation, logistics and distribution industries,

announced today it was selected to receive a $1.6 million

grant award from the U.S. Department of Energy Solar Energy

Technologies Office (SETO) to support a research and development

project aimed at decarbonizing the commercial transportation

industry.

The three-year project, set to begin next year in partnership

with the University of Delaware’s Center for Composite Materials,

focuses on integrating high-efficiency solar energy into

refrigerated trailers and truck bodies. This innovation will play a

pivotal role in making zero-emission mid-mile transportation a

commercially viable option.

“This project has the potential to revolutionize refrigerated

transport by reducing reliance on the electrical grid and

minimizing overall emissions,” said Michael Bodey, director of

technology discovery and innovation at Wabash. “While many of

today’s zero-emission products focus on tailpipe emissions, they

still draw power from energy grids, which often rely on

non-renewable sources. Our goal is to offer a truly green

solution—a well-to-wheel approach—that accounts for the full life

cycle of energy consumption, from production to usage.”

Wabash will use its proprietary EcoNex™ Technology, a composite

material designed to enhance thermal efficiency and reduce energy

consumption, while the University of Delaware will contribute its

proprietary TuFF technology, which utilizes recycled

aerospace-grade carbon fiber, to strengthen and lighten the

trailers and truck bodies.

“By incorporating lightweight solar panels and utilizing EcoNex

Technology in refrigerated trailers and truck bodies, we are

addressing two of the most significant barriers to electrification:

weight and energy consumption,” Bodey explained. “EcoNex not only

improves the insulation and performance of the trailers but also

contributes to overall weight reduction, making the solution even

more efficient.”

Batteries powering heavy trucks can weigh between 5,000 to

10,000 pounds, often limiting the payload capacity and drawing

significant energy from the electrical grid when charging. The goal

of this project is to develop enabling technologies that reduce the

weight and energy needs of these vehicles while offering fleet

customers greener, more efficient transportation options.

“TuFF is the world’s strongest short fiber composite that is

reciprocal with sustainable solutions to the mobility industry.

It’s great to collaborate with Wabash on building the most

sustainable solar panel integrated refrigerated trailer for the

trucking industry,” said Srikanth Pilla, UD PI and director of the

Center for Composites Materials at the University of Delaware.

Wabash is the only trailer and truck body original equipment

manufacturer (OEM) selected for this government grant, highlighting

its unique leadership position in sustainability and innovation. By

focusing on mid-mile transportation, the project seeks to create a

flexible solar energy system that can be CARB-compliant across

different vehicle types, without requiring fully electric platforms

to meet compliance.

This initiative is part of the DOE’s Silicon Solar Manufacturing

and Dual-use Photovoltaics Incubator Funding Program, which

supports advancements in PV technology across the supply chain and

fosters new markets for American products. The outcomes of this

project will help Wabash continue to evolve its technology

ecosystem and green its supply chain to better serve its customers’

sustainability goals.

Wabash: Changing How the World Reaches

You®Wabash (NYSE: WNC) is the visionary leader of

connected solutions for the transportation, logistics and

distribution industries that is Changing How the World Reaches

You®. Headquartered in Lafayette, Indiana, the company enables

customers to thrive by providing insight into tomorrow and

delivering pragmatic solutions today to move everything from first

to final mile. Wabash designs, manufactures, and services a diverse

range of products, including: dry freight and refrigerated

trailers, flatbed trailers, tank trailers, dry and refrigerated

truck bodies, structural composite panels and products, trailer

aerodynamic solutions, and specialty food grade processing

equipment. Learn more at onewabash.com.

University of Delaware Center for Composite

MaterialsThe University of Delaware Center for Composite

Materials (UD-CCM) was established in 1974. It has been recognized

as a Center of Excellence in Composites Materials and Structures

six times by the DOD, NSF, and FAA. Technology transition occurs

through the Industrial Consortium, with over 350 industrial

companies participating since 1978. UD-CCM has a 50-year history of

interdisciplinary research covering raw materials (fibers, fiber

sizings), intermediate forms (fabrics, prepregs), manufacturing

(forming, infusion, winding, pultrusion), joining technologies,

modeling and simulation tools, and inspection methods. Learn more

at https://www.ccm.udel.edu/.

Media Contact:Dana StelselDirector,

Communications(765)

771-5766dana.stelsel@onewabash.comInvestor

Relations: Ryan ReedVice President, Corporate Development

& Investor Relations(765) 490-5664ryan.reed@onewabash.com

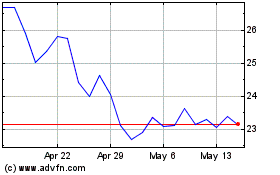

Wabash National (NYSE:WNC)

Historical Stock Chart

From Oct 2024 to Nov 2024

Wabash National (NYSE:WNC)

Historical Stock Chart

From Nov 2023 to Nov 2024