U.S. SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 6-K

REPORT OF FOREIGN PRIVATE ISSUER

PURSUANT TO RULE 13a-16 OR 15d-16 UNDER THE

SECURITIES EXCHANGE

ACT OF 1934

For the Month of October 2024

Nexa Resources S.A.

(Exact Name as Specified in its Charter)

N/A

(Translation of Registrant’s Name)

37A, Avenue J.F. Kennedy

L-1855, Luxembourg

Grand Duchy of Luxembourg

(Address of principal executive offices)

Indicate by check mark

whether the registrant files or will file annual reports under cover Form 20-F or Form 40-F.

Indicate by check mark

if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(1): ____

Indicate by check mark

if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(7): ____

Indicate by check mark

whether by furnishing the information contained in this Form, the registrant is also thereby furnishing the information to the Commission

pursuant to Rule 12g3-2(b) under the Securities Exchange Act of 1934.

If “Yes” is marked,

indicate below the file number assigned to the registrant in connection with Rule 12g3-2(b): Not applicable.

SIGNATURES

Pursuant to the requirements

of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto

duly authorized.

Date: October 31, 2024

| Nexa Resources S.A. |

| By:/s/ José Carlos del Valle |

| Name: José Carlos del Valle |

|

Title: Senior Vice President

of Finance and Group Chief Financial Officer |

| |

| |

EXHIBIT INDEX

Nexa Reports Third

Quarter 2024 Results including

Net Income of US$6 million and Adjusted EBITDA of US$183 million

Luxembourg, October

31, 2024 – Nexa Resources S.A. (“Nexa Resources”, “Nexa”, or the “Company”)

announces today its results for the three and nine-month periods ended on September 30, 2024.

CEO Message – Ignacio

Rosado

We are proud to report yet another favorable

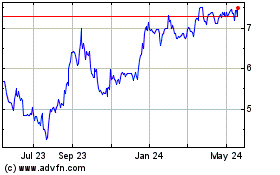

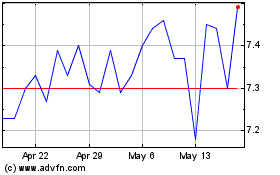

quarter, underscoring our unwavering commitment to operational excellence and financial discipline. As anticipated, zinc prices have remained

resilient, buoyed by solid fundamentals, the recent Federal Reserve interest rate cut, and China’s announced economic stimulus,

which we expect will positively impact demand in the upcoming months. Copper prices also performed well, driven by low treatment charges

due to tight supply and a positive demand outlook fueled by the energy transition.

Our operations delivered consistent production

levels and a modest increase in smelting sales quarter-over-quarter, supported by higher demand in our home market in 3Q24. Benefiting

from an improved pricing environment, which positively impacted by-products, alongside our disciplined cost management and ongoing optimization

initiatives, we successfully reduced our cash cost guidance in the mining segment, further strengthening our competitive position.

Safety remains a core priority, and we are

pleased with the substantial progress made across all fronts, which was enhanced by the safety plan introduced in early 2Q24.

In line with our strategy to optimize our

portfolio, we executed strategic transactions, including the sale of the Chapi mine and Pukakaqa project, allowing us to focus on our

key assets and the most promising opportunities.

Finally, due to the increase in our LTM

Adjusted EBITDA and positive cash flow generation this quarter, we achieved another reduction in our net leverage ratio, highlighting

our commitment to generating positive cash flow and enhancing our financial health. This not only strengthens our financial flexibility

as we prepare for the next strategic steps but also solidifies our position as a company dedicated to creating shared value for our investors

and the communities we serve. Looking ahead, we remain confident that zinc and copper prices will continue to receive positive support

from global fundamentals, reinforcing our outlook for a strong close to the year.

Summary of Financial

Performance

| US$ million (except per share amounts) |

3Q24 |

2Q24 |

3Q23 |

9M24 |

9M23 |

| Net revenues |

709 |

736 |

649 |

2,026 |

1,943 |

| Gross profit |

127 |

180 |

68 |

395 |

230 |

| Net income (loss) |

6 |

(70) |

(64) |

(76) |

(183) |

| EBITDA (1) |

167 |

94 |

72 |

388 |

149 |

| Basic and diluted loss per share |

(0.04) |

(0.58) |

(0.57) |

(0.80) |

(1.49) |

| Adjusted net income (loss) (1) |

22 |

42 |

(50) |

53 |

(35) |

| Adjusted EBITDA (1) |

183 |

206 |

87 |

517 |

296 |

| Adjusted basic and diluted earnings (loss) per share (1) |

0.02 |

0.14 |

(0.44) |

0.00 |

(0.41) |

| Cash provided by operating activities before working capital (1) (2) |

198 |

138 |

52 |

423 |

229 |

| Capex |

53 |

64 |

82 |

191 |

198 |

| Free cash flow (1) |

51 |

149 |

14 |

56 |

(84) |

| Total cash (3) |

525 |

474 |

422 |

525 |

422 |

| Net debt (1) |

1,409 |

1,450 |

1,307 |

1,409 |

1,307 |

| Net Debt/LTM Adj. EBITDA |

2.2x |

2.7x |

3.1x |

2.2x |

3.1x |

(1) Refer

to “Use of Non-IFRS Financial Measures” for further information. Adjusted EBITDA, adjusted net income (loss) and adjusted

EPS, exclude the items presented in the “Net Income (Loss) reconciliation to Adjusted EBITDA” section of this earnings release.

For details on segment definition and accounting policy, please refer to explanatory note 2 – “Information by business segment”

in the “Condensed consolidated interim financial statements at and for the three and nine-month periods ended on September 30, 2024.”

(2) Working

capital variations in 3Q24 had a negative impact of US$43 million, totaling US$184 million in 9M24. Working capital variations in 3Q23

had a positive impact of US$88 million, totaling positive impact of US$52 million in 9M23.

(3) Cash,

cash equivalents and financial investments.

Executive Summary

Operational Performance

| § | Zinc production for the quarter totaled 83kt, down by 5% from 3Q23, primarily

due to lower average zinc grades at Vazante and El Porvenir, as well as the absence of contributions from Morro Agudo, which ceased operations

on April 30, 2024. Compared to 2Q24, zinc production remained relatively flat, with higher volumes from Vazante, El Porvenir, and Atacocha,

partially offset by the absence of contributions from Morro Agudo and slightly lower volumes from Cerro Lindo and Aripuanã. |

| § | Run-of-mine mining cost in 3Q24 was US$46/t, up 6%

compared to 3Q23, due to lower treated ore volumes due to the cessation of mining operations at Morro Agudo, partially offset by lower

operating costs related to third-party services, personnel costs, energy costs and materials

(e.g. explosives and related items). Compared to 2Q24, run-of-mine mining cost decreased by 5%, primarily

due to lower third-party services, higher treated ore volumes and lower variable costs. Run-of-mine mining cost in 3Q24 and 9M24, performed

within the guidance range for the year. |

| § | Mining cash cost net of by-products[1]

in 3Q24 decreased to US$(0.01)/lb compared to US$0.34/lb in 3Q23. This decrease was

primarily due to lower TCs and higher by-products contribution, which were partially offset by increased operating costs. Compared to

2Q24, cash cost decreased by US$0.04/lb, impacted by lower operating costs related to third-party services and maintenance, as well as

slightly higher zinc sales volumes, which were partially offset by lower by-products contribution. Mining cash cost net of by-products

in 3Q24 was below the lower end of our updated annual guidance range, while the 9M24 mining cash cost net of by-products was within our

updated guidance range for the year. |

| § | The smelting segment produced a total of 153kt of zinc metal and oxide

in 3Q24, up 2% year-over-year, primarily driven by higher volumes at Cajamarquilla. Quarter-over-quarter, production was relatively flat,

as higher output was partially offset by lower production at the Juiz de Fora smelter due to scheduled maintenance in the period. |

| § | In 3Q24, zinc metal and oxide sales were 153kt, down 1% from 3Q23. Compared

to 2Q24, metal sales increased by 3%, following higher production volumes in Cajamarquilla and Três Marias, along with strong demand

in our domestic market. |

| § | Smelting conversion cost was US$0.32/lb in 3Q24 compared with US$0.29/lb

in 3Q23, mainly due to higher operational costs related to maintenance expenses, partially offset by the positive impact of foreign exchange

variations. Compared to 2Q24, conversion cost was up by 6%, driven by higher variable and energy costs mainly due to one-off effects in

Cajamarquilla, partially offset by a decrease in maintenance

expenses. Smelting conversion cost for both 3Q24 and 9M24 remained within the guidance

range. |

[1]

Our cash cost net of by-products credits is measured with respect to zinc sold.

| | | |

| |  | 2 |

| § | Smelting cash cost1 was US$1.16/lb in

3Q24 compared to US$1.01/lb in 3Q23. This increase was mainly due to higher raw material costs

attributed to higher zinc prices and lower TCs, alongside increased operating expenses, partially offset by higher by-products contribution.

Compared to 2Q24, cash cost decreased by 3%, primarily due to lower zinc prices, impacting our concentrate purchases and higher by-products

contribution, which were partially offset by higher operating costs. Smelting cash cost in both

3Q24 and 9M24 also remained within the guidance range. |

Financial Performance

| § | Net revenues in 3Q24 were US$709 million, up 9% from US$649 million

in 3Q23. This increase was primarily driven by higher LME metal prices (except for lead), partially offset by slightly lower smelting

sales volumes and a lower net premium. The LME average prices for zinc and copper rose by 14% and 10%, respectively, while lead prices

decreased by 6% compared to the same period in 2023. Compared to 2Q24, net revenues decreased by 4%, mainly due to lower LME base metal

prices and lower by-products contribution, partially offset by higher smelting sales and a slight improvement net premium. For 9M24, net

revenues totaled US$2,026 million, up by 4% compared to the same period a year ago. |

| § | In 3Q24, net income amounted to US$6 million,

resulting in basic and diluted loss per share attributable to Nexa's shareholders of US$0.04. In 9M24,

net loss totaled US$76 million, resulting in basic and diluted loss per share attributable to Nexa's shareholders of US$0.80. |

| § | Adjusted

net income in 3Q24 was US$22 million, with adjusted net income attributable to Nexa’s shareholders

of US$2.4 million, resulting in adjusted basic and diluted earnings per share of US$0.02. In 9M24, adjusted

net income was US$53 million, with adjusted net income attributable to Nexa’s shareholders of US$0.4 million, resulting in adjusted

basic and diluted earnings per share of US$0.00. Refer to our “Net Income (Loss)” section for further details. |

| § | Adjusted EBITDA[2]

in 3Q24 was US$183 million compared to US$87 million in 3Q23 and US$206 million in

2Q24. The year-over-year increase was primarily driven by higher by-products contribution, higher zinc prices, and lower mineral exploration

and project evaluation expenses for the quarter. We reaffirmed our exploration and project expenses guidance for the year. The quarter-over-quarter

decrease was attributed to higher fixed and variable costs and lower by-products contribution, partially offset by increased

smelting sales volume. In 9M24, Adjusted EBITDA amounted to US$ 517 million, up by 75% compared to

the same period a year ago. |

| § | Adjusted EBITDA margin of 25.8% in 3Q24, decreased 2.2bps and increased

12.4bps compared to 2Q24 and 3Q23, respectively. |

| § | Adjusted EBITDA for the mining segment in 3Q24 was US$128 million compared

to US$136 million in 2Q24. This decrease was mainly driven by lower LME metal prices, higher fixed costs and lower mining sales volumes,

which were partially offset by higher by-products contribution. Compared to 3Q23, Adjusted EBITDA increased by 190%, mainly due to higher

by-products contribution, higher zinc prices, the positive impact from FX variations, and lower mineral exploration and project evaluation

expenses. |

| § | Adjusted EBITDA for the smelting segment in 3Q24 was US$55 million compared

with US$69 million in 2Q24. This decrease was mainly driven by higher variable costs and lower TCs, partially offset by lower zinc prices,

which positively impacted the purchase of zinc concentrate and slightly higher net premium, in addition to higher by-products contribution

and higher sales volume. Compared to 3Q23, Adjusted EBITDA increased by 10%. |

[2]

Adjusted EBITDA excludes the items presented in the “Net Income (Loss) reconciliation to Adjusted EBITDA” section of this

earnings release – US$16 million in 3Q24, totaling US$129 million in 9M24.

| | | |

| |  | 3 |

Financial Position,

Investments and Financing

| § | Total cash[3]

at September 30, 2024, was US$525 million compared to US$474 million at June 30,

2024. Our available liquidity in 3Q24 was US$845 million, including our undrawn sustainability-linked revolving credit facility of US$320

million. This total available liquidity is sufficient to cover all financial commitments for the next 3.9 years. |

| § | In 3Q24, free cash flow was positive at US$51 million,

primarily driven by positive operating cash flows and lower CAPEX investments (including Sustaining and HS&E) of US$55 million. These

positive effects were partially offset by a negative working capital variation of US$43 million, mainly due to increased inventory levels,

a reduction in other liabilities, primarily from interest updates on provisions and asset retirement obligations payments, and a decrease

in trade payables. Despite a negative year-to-date position,

we remain focused on implementing initiatives such as enhanced receivable management to reverse this position in the next quarter. For

further details, please refer to the “Net cash flows from operating activities excluding working capital variations and free cash

flow - Reconciliation” section. |

| § | Net debt to Adjusted EBITDA ratio for the last twelve months (“LTM”)

decreased to 2.2x at the end of 3Q24, compared with 2.7x at the end of 2Q24 and 3.1x at the end of 3Q23. The quarter-over-quarter reduction

was primarily driven by higher LTM Adjusted EBITDA and a reduction in net debt, reflecting our ongoing commitment and strategy to reduce

leverage. |

Environmental,

Social and Governance (“ESG”) and Corporate Highlights

| § | In 3Q24, Nexa expanded its “Cloud Talent for Women” program,

benefiting an additional 75 women in the state of Mato Grosso and communities near our Aripuanã and Três Marias operations.

Developed in collaboration with Amazon Web Services Inc., this initiative provides digital training for women pursuing technology careers,

supporting Nexa’s income generation programs. |

| § | In August 2024, Nexa received the Gold Seal from the Brazilian GHG Protocol

Program, awarded by the Fundação Getúlio Vargas. This recognition underscores Nexa’s commitment to transparency

and excellence in greenhouse gas emissions reporting, based on 2023 data. With one of the lowest Scope 1 and Scope 2 CO₂ emission

intensities in the global zinc industry, Nexa remains dedicated to reducing its scope 1 emissions by 20% by 2030, reaffirming its commitment

to mitigate climate change. |

| § | In August 2024, as part of Nexa’s circular economy initiatives,

the Company announced a new partnership with WEG, a Brazilian multinational specialized in electrical equipment and automation systems.

WEG will work with Nexa to develop liquid anticorrosive paints using jarosite, a residue from zinc smelting. This project, stemming from

Nexa's open innovation program with universities, represents an expected investment of approximately US$0.5 million, supported by the

Brazilian Innovation Agency (“FINEP”). With tests completed, and pending further technical and economic viability, WEG may

purchase jarosite for production, potentially reducing waste levels at our Juiz de Fora smelter. The resulting product, tentatively named

“Jaropaint” could be applied to carbon steel surfaces to protect against corrosion. |

| § | In August 2024, Nexa also opened registrations for the Cajamarquilla

Children's Choir 2024. This program benefits 40 children from communities surrounding our Cajamarquilla smelter and aims to nurture musical

talent through in-person classes led by expert instructors, including the Director of the National Children’s Choir of Peru. Running

through December 2024, this initiative underscores Nexa’s commitment to cultural enrichment in the regions where we operate and

support community growth. |

| § | In August 2024, for the fifth consecutive year, Nexa was named one

of the five most innovative companies in the Mining, Metallurgy, and Steel sectors by the Valor Inovação Brasil 2024

Awards, one of the most prestigious innovation awards in in Brazil. Climbing 42 positions in the overall rankings, Nexa’s consistent recognition

underscores our commitment to innovation as a driver of business excellence, competitiveness, and socio-environmental growth in our operational

regions. |

[3]

Cash and cash equivalents and financial investments.

| | | |

| |  | 4 |

| § | In September 2024, also as part of Nexa’s circular economy initiatives,

we completed a pilot test at a partner company’s site. On average, 0.5 tons of modified tailings (mainly SiO2 and CaCO3) from our

Atacocha mine were successfully evaluated as cementitious material, with the potential to replace 30% of traditional cement in standard

blends. This project aims to monetize waste by developing partnerships, evaluating viable technologies, and identifying trade routes for

these materials, while also reducing the need for disposal in our tailings dams and creating a new revenue stream for Nexa. |

| § | In September 2024, more than 3,500 employees across Peru and Brazil

joined Nexa’s Internal Workplace Accident Prevention Week 2024. United by a shared commitment to health and safety, employees engage

in activities including awareness sessions, challenges, fairs, workshops, and recognition programs. |

| § | In September 2024, Nexa received two honors at the Brazil Mining Best

Practices Awards during the Exposibram 2024, Latin America’s largest mining trade fair by the Brazilian Mining Institute (“IBRAM”).

Nexa earned first place in the energy efficiency category for pioneering bio-oil to reduce emissions in zinc oxide production at the Três

Marias smelter and placed third in the innovation category, reinforcing our dedication to sustainable technology and solutions. |

| § | In August and September 2024, S&P and Fitch Ratings, respectively,

reaffirmed Nexa’s 'BBB-' investment grade rating maintaining a 'stable' outlook. |

| § | On October 1, 2024, we announced changes to our Board of Directors and senior leadership team. Mr. João Schmidt, CEO of

Votorantim S.A., stepped down as a Director of Nexa Resources S.A., effective October 1, 2024, after serving in this role since 2016.

Simultaneously, we appointed Mr. Flavio Aidar to our Board of Directors. Mr. Aidar holds a degree in Business Administration from Fundação

Getúlio Vargas and brings experience in the industrial, infrastructure, and mining sectors. His extensive board experience across

various countries and financial markets will provide a unique and valuable perspective as we continue to explore new avenues for growth

and maximize shareholder value. |

| § | Also in October 2024, we announced that Mr. Marcio Godoy, Senior Vice

President of Technical Services and Projects at Nexa, resigned, effective October 15, 2024. His responsibilities were distributed across

other management functions to ensure continuity and maintain operational efficiency. |

Growth Strategy

and Asset Portfolio

| § | We remain committed to generating free cash flow and continually evaluate our capital allocation

framework, which prioritizes sustaining capital, brownfield mineral exploration, and ESG and Health, Safety, and Environment (“HS&E”)

initiatives. |

| § | In September 2024, we announced the sale of the Pukaqaqa

greenfield project and our non-operational Peruvian subsidiary, Minera Pampa de Cobre S.A.C (the owner of the Chapi mine). These

sales are in line with Nexa’s portfolio optimization strategy, ensuring efficient capital allocation to our highest-return assets. |

| § | In 3Q24, Nexa has achieved important

milestones in Cerro Pasco Integration Project, which encompasses two main phases. During the quarter, substantial strides were made

across various work fronts, particularly with the submission for internal approval of the Tailings Pumping System, the central

element of Phase I. This phase aims to expand tailings storage capacity at the Pasco Complex, thereby extending substantially the

operational life of the site.The investment plan includes constructing a tailings treatment plant and its auxiliary structures at El

Porvenir, and a 6 km pipeline on an existing route (mostly underground) to connect it to Atacocha’s tailings storage facility,

allowing the Complex to operate for over a decade and representing a pivotal step toward sustainability. |

The

investment plan includes constructing a tailings treatment plant and its auxiliary structures at El Porvenir, and a 6 km pipeline on an

existing route (mostly underground) to connect it to Atacocha’s tailings storage facility, allowing the Complex to operate for over

a decade and representing a pivotal step toward sustainability.

| | | |

| |  | 5 |

The

capital expenditure for the Tailings Pumping System is estimated to be between US$85 million and US$90 million and is scheduled for execution

from 2025 to 2026, with operations expected to commence in 1H27. Additionally, Phase I also includes upgrades to the tailings facilities

at both El Porvenir and Atacocha, as well as water and effluent treatment systems, with construction planned for 2027-2028 following the

completion of environmental impact assessments.

Phase

II aims to link, through the construction of a 2.3 kilometers underground tunnel at a deeper level, the El Porvenir and Atacocha mines

and upgrade the El Porvenir shaft, which is expected to unlock access to high-grade minerals. To ensure efficient development, each phase

is designed to be adaptable. Support activities, such as technical reviews, environmental studies, and community engagement, are also

progressing as planned. We are confident in the long-term value this project will generate for Nexa and remain focused on its successful

execution.

| | | |

| |  | 6 |

Outlook

Production and

Sales Guidance

Guidance is based on several assumptions

and estimates and is subject to the continuous evaluation of several factors, including, but not limited to, metal prices, operational

performance, maintenance, input costs and exchange rates.

| § | As of date of this Earnings Release, Nexa reaffirms its 2024 consolidated

production guidance for all metals, including zinc and lead, as updated per operation on October 24, 2024, based on the aforementioned

factors. The guidance and 4Q24 outlook for mining production, zinc sales, cash cost for mining and smelting segments, capital expenditures,

exploration, project evaluation, and other expenses is outlined below. |

| o | Cerro Lindo: as

per the mining plan for the year, zinc production in 4Q24 is expected to be slightly lower than in 3Q24,

primarily due to lower average head grades. Copper production is expected to increase, driven by access to areas with higher average grades. |

| o | El Porvenir: based on mine sequencing, zinc production in 4Q24

is expected to increase compared to 3Q24, driven by higher mined ore volumes and higher average grades. Additionally, lead and silver

production is expected to increase, following the same trend, as higher average head grades for these metals are anticipated. |

| o | Atacocha: we expect zinc production in 4Q24 to remain at the

same level as in 3Q24. Lead and silver production are also expected to increase, driven by mining activities in areas with higher grades. |

| o | Vazante: ore throughput, zinc head grade, and zinc production

in 4Q24 are expected to remain at the same level as in 3Q24. |

| o | Aripuanã: we anticipate improved operational performance

in 4Q24 compared to 3Q24, driven by sustained higher utilization capacity, enhanced plant feed and throughput rates, and stable concentrate

quality within commercial specifications. Additionally, we expect higher metallurgical recoveries, with zinc and lead production projected

to increase, while copper production is expected to remain at the same level as 3Q24. |

Mining segment – production

| Mining production |

|

9M24 |

|

2024e |

| (Metal in concentrate) |

|

Updated |

| |

|

|

|

|

|

|

|

| Zinc |

kt |

|

252 |

|

323 |

- |

381 |

| Cerro Lindo |

|

|

71 |

|

84 |

- |

99 |

| El Porvenir |

|

|

38 |

|

50 |

- |

58 |

| Atacocha |

|

|

8 |

|

9 |

- |

11 |

| Vazante |

|

|

106 |

|

140 |

- |

163 |

| Morro Agudo (1) |

|

|

7 |

|

7 |

- |

7 |

| Aripuanã |

|

|

22 |

|

31 |

- |

42 |

| |

|

|

|

|

|

|

|

| Copper |

kt |

|

27 |

|

30 |

- |

35 |

| Cerro Lindo |

|

|

22 |

|

24 |

- |

28 |

| El Porvenir |

|

|

0.2 |

|

0.2 |

- |

0.3 |

| Aripuanã |

|

|

4.5 |

|

5.7 |

- |

7.3 |

| |

|

|

|

|

|

|

|

| Lead |

kt |

|

52 |

|

66 |

- |

82 |

| Cerro Lindo |

|

|

12 |

|

13 |

- |

17 |

| El Porvenir |

|

|

19 |

|

25 |

- |

32 |

| Atacocha |

|

|

9 |

|

12 |

- |

13 |

| Vazante |

|

|

0.7 |

|

1 |

- |

1 |

| Morro Agudo (1) |

|

|

2.3 |

|

2.3 |

- |

2.3 |

| Aripuanã |

|

|

8.5 |

|

12 |

- |

16 |

| |

|

|

|

|

|

|

|

| Silver |

MMoz |

|

9 |

|

11 |

- |

13 |

| Cerro Lindo |

|

|

3.4 |

|

4.0 |

- |

4.2 |

| El Porvenir |

|

|

3.3 |

|

4.6 |

- |

5.4 |

| Atacocha |

|

|

0.9 |

|

1.1 |

- |

1.2 |

| Vazante |

|

|

0.4 |

|

0.3 |

- |

0.5 |

| Aripuanã |

|

|

0.8 |

|

1.0 |

- |

1.5 |

(1)

Considers only the four months of operations from January to April 2024.

| | | |

| |  | 7 |

Smelting segment – sales

| § | Metal sales guidance also remains unchanged at 580-605kt. |

| o | Peru: we anticipate higher production at Cajamarquilla in 4Q24

compared to 3Q24, driven by stable performance and consistent production levels. |

| o | Brazil: at Três Marias, we expect production in 4Q24 to

be slightly lower than in 3Q24, while production at Juiz de Fora is expected to remain at similar levels. |

| Smelting sales |

|

9M24 |

|

2024e |

| |

|

|

|

|

|

|

|

| Zinc metal |

kt |

|

413 |

|

545 |

- |

565 |

| Cajamarquilla |

|

|

243 |

|

315 |

- |

325 |

| Três Marias |

|

|

110 |

|

155 |

- |

160 |

| Juiz de Fora |

|

|

60 |

|

75 |

- |

80 |

| |

|

|

|

|

|

|

|

| Zinc oxide |

kt |

|

26 |

|

35 |

- |

40 |

| Três Marias |

|

|

26 |

|

35 |

- |

40 |

| |

|

|

|

|

|

|

|

| Metal Sales |

kt |

|

439 |

|

580 |

- |

605 |

Nexa will continue to monitor risks associated

with global supply chain disruptions, which could be exacerbated, among other factors, by the ongoing Russia-Ukraine war, the Middle-East

conflict, unusual weather conditions, the global recession, and its potential impact on the demand for our products, inflationary cost

pressure, metal price volatility, local community or union protests, and changes to the political situations or regulatory frameworks

in the countries in which we operate that could affect our production levels and our costs. Refer to “Risks and Uncertainties”

and “Cautionary Statement on Forward-Looking Statements” for further information.

Cash Costs

| § | Nexa reaffirms its 2024 cost ROM guidance at our mining operations,

along with the conversion cost and cash cost net of by-products credits at our smelting operations, despite a challenging inflationary

environment. However, on October 24, 2024, we reduced our 2024 cash cost guidance for the mining segment. This reduction was primarily

due to higher LME metal prices, year-to-date performance, increased by-products contribution (both in prices and volumes), and slightly

lower treatment charges (“TCs”). Nexa is confident that the adjusted 2024 consolidated cash cost guidance for its mining segment,

and the reaffirmed cash cost guidance for our smelting segment will be achieved. |

| o | Mining and smelting volumes are expected to slightly increase in 4Q24

compared to 3Q24, remaining within the guidance ranges noted above. |

| | | |

| |  | 8 |

| o | We anticipate that ongoing improvements in operational efficiency and

cost management will positively impact on our overall performance. Several initiatives are already being implemented across our mines

and smelters. |

| o | Commodity prices have been revised for 2024e – (Zn: US$1.21/lb,

Cu: US$4.14/lb, Pb: US$0.95/lb, Ag: US$27.8/oz, Au: US$2,328/oz), versus previous 2024e – (Zn: US$1.13/lb, Cu: US$3.76/lb, Pb: US$0.95/lb,

Ag: US$23.5/oz, Au: US$1,945/oz). Nexa’s C1 cash cost is sensitive to by-products prices and volumes, which may affect the results

of our final costs. |

| o | Foreign exchange rates assumptions have been updated to (BRL/USD: 5.25

and Soles/USD: 3.74), versus previous 2024e – (BRL/USD: 4.90 and Soles/USD: 3.67). |

| o | Zinc TCs assumptions for the year have been updated to US$165/t concentrate,

versus the previous 2024e US$174/t concentrate. |

| Mining Operating costs |

|

Cost ROM

(US$/t) |

|

Cash Cost

(US$/lb) |

|

Cost ROM

(US$/t) |

|

Cash Cost

(US$/lb) |

| |

|

|

|

| |

9M24 |

|

9M24 |

|

2024e |

|

2024e |

| |

|

|

|

Updated |

| |

|

|

|

|

|

|

|

|

|

|

|

|

| Mining (1) |

|

46.0 |

|

0.09 |

|

44.0 |

- |

51.4 |

|

0.03 |

- |

0.20 |

| Cerro Lindo |

|

42.6 |

|

(0.39) |

|

41.0 |

- |

45.0 |

|

(0.56) |

- |

(0.28) |

| El Porvenir |

|

63.6 |

|

0.13 |

|

58.4 |

- |

71.6 |

|

(0.09) |

- |

0.18 |

| Atacocha |

|

33.8 |

|

(0.69) |

|

34.3 |

- |

43.2 |

|

(0.85) |

- |

(0.59) |

| Vazante |

|

48.9 |

|

0.50 |

|

55.8 |

- |

63.6 |

|

0.46 |

- |

0.52 |

| Morro Agudo (2) |

|

40.8 |

|

0.93 |

|

27.9 |

- |

40.0 |

|

0.93 |

- |

0.93 |

(1) C1 Weighted Cash cost net of

by-products credits is measured with respect to zinc sold per mine.

(2) Considers only the four months

of operations from January to April 2024.

Note: Consolidated cash cost does not

include Aripuanã.

| Smelting Operating costs |

|

Conversion cost

(US$/lb) |

|

Cash Cost

(US$/lb) |

|

Conversion cost

(US$/lb) |

|

Cash Cost

(US$/lb) |

| |

|

|

|

| |

9M24 |

|

9M24 |

|

2024e |

|

2024e |

| |

|

|

|

|

|

|

|

|

|

|

|

|

| Smelting (3) |

|

0.31 |

|

1.11 |

|

0.29 |

- |

0.32 |

|

1.07 |

- |

1.18 |

| Cajamarquilla |

|

0.28 |

|

1.09 |

|

0.29 |

- |

0.32 |

|

1.02 |

- |

1.13 |

| Três Marias |

|

0.30 |

|

1.12 |

|

0.25 |

- |

0.27 |

|

1.12 |

- |

1.23 |

| Juiz de Fora |

|

0.43 |

|

1.21 |

|

0.38 |

- |

0.42 |

|

1.17 |

- |

1.28 |

(3) C1 Weighted Cash cost net

of by-products credits is measured with respect to zinc sold per smelter.

| § | In 9M24, Mining C1 cash cost of US$0.09/lb was in line with our updated

2024 guidance, primarily driven by higher by-products contribution, particularly from Cerro Lindo, and lower TCs across all units. The

run-of-mine mining costs of US$46.0/t was in line with our 2024 guidance. For further information, please see the section “Business

performance – Mining segment.” |

| § | In 9M24, Smelting C1 cash cost of US$1.11/lb and conversion cost of

US$0.31/lb were in line with our 2024 guidance. For further information, please see the section “Business performance – Smelting

segment.” |

Capital Expenditures

(“CAPEX”) Guidance

| § | Nexa invested US$53 million in 3Q24, nearly

all of which was sustaining, which includes CAPEX to sustain operations as well as mine development. In

9M24, total CAPEX amounted to US$191 million. |

| | | |

| |  | 9 |

| § | The depreciation of the Brazilian real against the U.S. dollar resulted

in a positive impact of US$3.1 million in the quarter, totaling US$5 million in 9M24. |

| § | Our 2024 CAPEX guidance has been revised downward by US$11 million,

bringing the updated figure to US$300 million (vs. US$311 million in the previous guidance). |

| CAPEX |

|

9M24 |

|

2024e |

| (US$ million) |

|

|

Updated |

| Non-Expansion |

|

198 |

|

297 |

| Sustaining (1) |

|

185 |

|

261 |

| HS&E |

|

7 |

|

20 |

| Others (2) |

|

6 |

|

16 |

| |

|

|

|

|

| Expansion projects (3) |

|

2 |

|

3 |

| Reconciliation to Financial Statements (4) |

|

(9) |

|

- |

| TOTAL |

|

191 |

|

300 |

(1) Investments

in tailing dams are included in sustaining expenses.

(2) Modernization,

IT and others.

(3) Includes

Vazante deepening, among several other projects to improve operational performance.

(4) The amounts

are mainly related to capitalization of interest net of advanced payments for imported materials and tax credits.

Exploration &

Project Evaluation and Other Expenses Guidance

| § | In 3Q24, we invested US$15 million in exploration and project evaluation,

totaling US$45 million in 9M24. |

| § | In 3Q24, we also allocated a total of US$5 million to technology and

community initiatives, totaling US$12 million in 9M24. These investments aim to enhance our current operations and to further contribute

to the social and economic development of our host communities. |

| § | Our total 2024 guidance for exploration and project evaluation, and

other operating expenses remains unchanged at US$72 million and US$21 million, respectively. |

| § | As part of our long-term strategy, we remain focused on replacing and

increasing mineral reserves and resources. We expect to continue advancing our exploration activities, primarily by identifying new ore

bodies and upgrading resources classification through infill drilling campaigns. |

| Other Operating Expenses |

|

9M24 |

|

Guidance 2024 |

| (US$ million) |

|

|

| Exploration |

|

37 |

|

58 |

| Mineral Exploration |

|

28 |

|

42 |

| Mineral rights |

|

4 |

|

6 |

| Sustaining (mine development) |

|

4 |

|

10 |

| |

|

|

|

|

| Project Evaluation |

|

8 |

|

14 |

| |

|

|

|

|

| Exploration & Project Evaluation |

|

45 |

|

72 |

| |

|

|

|

|

| Other |

|

12 |

|

21 |

| Technology |

|

2 |

|

4 |

| Communities |

|

9 |

|

17 |

Note: Exploration and project evaluation expenses

consider several stages of development, from mineral potential definition, R&D, and subsequent scoping and pre-feasibility studies

(FEL1 and FEL2).

| | | |

| |  | 10 |

Earnings Release

3Q24

This Earnings Release should be read

in conjunction with the “Condensed consolidated interim financial statements at and for the three and nine-month periods ended on

September 30, 2024.” This document contains forward-looking statements.

Table of contents

| Consolidated performance |

12 |

| Business performance – Mining |

18 |

| Business performance – Smelting |

29 |

| Liquidity and Indebtedness |

37 |

| Cash flows |

39 |

| Others |

40 |

| Market scenario |

42 |

| Risks and Uncertainties |

44 |

| Use of Non-IFRS Financial Measures |

45 |

| Cautionary Statement on Forward-Looking Statements |

47 |

| Appendix |

49 |

UPCOMING EVENT

Earnings Conference

Call

Date: Friday, November 1, 2024 –

9:00am (EST)

Dial In

US: +1-833-816-1265

Canada: +1-647-484-8814

Brazil: +55 11 3181-8565

International: +1-412-317-5635

Conference ID: Nexa Resources

Live audio webcast with slide presentation

will be available on:

https://ir.nexaresources.com

| | | |

| |  | 11 |

Consolidated performance

Selected financial

information

US$ million

(except where otherwise indicated) |

3Q24 |

2Q24 |

3Q23 |

9M24 |

9M23 |

| |

|

|

|

|

|

| Net Revenues |

709 |

736 |

649 |

2,026 |

1,943 |

| Mining |

325 |

377 |

273 |

996 |

809 |

| Smelting |

524 |

508 |

484 |

1,450 |

1,493 |

| Intersegment results | Adjustments |

(140) |

(149) |

(107) |

(421) |

(358) |

| |

|

|

|

|

|

| Cost of Sales |

(583) |

(556) |

(581) |

(1,631) |

(1,714) |

| Mining |

(247) |

(256) |

(245) |

(755) |

(744) |

| Current Operations |

(203) |

(215) |

(203) |

(627) |

(600) |

| Aripuanã |

(44) |

(42) |

(42) |

(128) |

(143) |

| Smelting |

(474) |

(450) |

(439) |

(1,297) |

(1,322) |

| Intersegment results | Adjustments |

139 |

150 |

102 |

421 |

352 |

| |

|

|

|

|

|

| Selling, general and administrative |

(29) |

(30) |

(33) |

(93) |

(94) |

| Mining |

(14) |

(16) |

(16) |

(47) |

(45) |

| Smelting |

(13) |

(14) |

(15) |

(43) |

(46) |

| Intersegment results | Adjustments |

(2) |

0 |

(2) |

(3) |

(3) |

| |

|

|

|

|

|

| Depreciation and amortization |

82 |

74 |

76 |

234 |

224 |

| Mining |

63 |

54 |

54 |

174 |

163 |

| Smelting |

19 |

19 |

21 |

58 |

60 |

| Intersegment results | Adjustments |

0 |

1 |

0 |

1 |

1 |

| |

|

|

|

|

|

| Adjusted EBITDA (1) |

183 |

206 |

87 |

517 |

296 |

| Mining |

128 |

136 |

44 |

342 |

110 |

| Smelting |

55 |

69 |

50 |

174 |

191 |

| Intersegment results | Adjustments |

0 |

1 |

(7) |

1 |

(4) |

| Adj. EBITDA margin (%) |

25.8% |

28.0% |

13.3% |

25.5% |

15.2% |

| |

|

|

|

|

|

| Net income (loss) |

6 |

(70) |

(64) |

(76) |

(183) |

| Attributable to Nexa's shareholders |

(5) |

(77) |

(75) |

(107) |

(197) |

| Attributable to non-controlling interests |

11 |

7 |

10 |

31 |

14 |

| |

|

|

|

|

|

| Basic and diluted loss per share |

(0.04) |

(0.58) |

(0.57) |

(0.80) |

(1.49) |

| |

|

|

|

|

|

| Adjusted net income (loss) (1) |

22 |

42 |

(50) |

53 |

(35) |

| Attributable to Nexa's shareholders |

2.4 |

19 |

(58) |

0.4 |

(54) |

| Attributable to non-controlling interests |

19 |

23 |

8 |

53 |

19 |

| |

|

|

|

|

|

| Adjusted basic and diluted earnings (loss) per share (1) |

0.02 |

0.14 |

(0.44) |

0.00 |

(0.41) |

(1) Refer to “Use of Non-IFRS Financial

Measures” for further information. Adjusted EBITDA, adjusted net income (loss) and adjusted EPS, exclude the items presented in

the “Net Income (Loss) reconciliation to Adjusted EBITDA” section of this earnings release. For details on segment definition

and accounting policy, please refer to explanatory note 2 – “Information by business segment” in the “Condensed

consolidated interim financial statements at and for the three and nine-month periods ended on September 30, 2024.” This is a note

about segments, and one of the explanations for the new adjustment for cash dividend at the consolidated level was to keep consistency

with segment information.

| | | |

| |  | 12 |

Net revenues

In 3Q24, net revenues totaled US$709 million,

up 9% year-over-year, primarily driven by higher LME metal prices (except for lead), which was partially offset by slightly lower smelting

sales volumes and a lower net premium. The LME average prices for zinc and copper rose by 14% and 10%, respectively, while lead prices

decreased by 6%, compared to the same period in 2023. For further details on metal prices, please refer to the “Market Scenario”

section.

Compared to 2Q24, net revenues decreased

by 4%, mainly due to lower LME base metal prices and lower by-products contribution, partially offset by higher smelting sales volume

and a slightly higher net premium.

In 9M24, net revenues amounted to US$2,026

million, up by 4% compared to the same period a year ago, as a result of the aforementioned reasons.

Cost of Sales

In 3Q24, cost of sales amounted to US$583

million, remaining relatively flat year-over-year. This stability was primarily driven by slightly lower smelting and mining sales volumes,

and a positive hedge effect. These positive factors were offset by higher maintenance expenses in both segments, increased third-party

services in our mining segment, lower TCs from third-party concentrates, and higher energy expenses. Compared to 2Q24, cost of sales increased

by 5%, mainly due to increased smelting and mining sales volumes, higher operational costs, and lower TCs from third-party concentrates,

which were partially offset by the positive effect of lower zinc prices on zinc concentrates purchase, as well as slightly lower third-party

services and employee benefit expenses.

In 9M24, cost of sales amounted to US$1,631

million, down by 5% compared to the same period a year ago, largely due to the aforementioned reasons.

Mineral exploration

and Project evaluation

In 3Q24, mineral exploration and project

evaluation investments were US$15 million, compared to US$26 million in 3Q23, mainly driven by lower project evaluation expenses. In 9M24,

mineral exploration and project evaluation investments amounted to US$45 million.

For additional information about our exploration

results in the third quarter 2024, please refer to our 3Q24 Exploration Report published on October 24, 2024.

SG&A

In 3Q24, SG&A expenses totaled US$29

million, down by 11% compared to 3Q23. This reduction was primarily due to a decrease in the impairment provision for trade accounts receivable

and slightly lower third-party service costs in support areas, partially offset by higher employee benefit expenses. SG&A expenses

also decreased by 2% compared to 2Q24.

In 9M24, SG&A expenses amounted to

US$93 million, down by 1% compared to the same period a year ago, primarily due to higher employee benefit expenses.

Adjusted EBITDA

In 3Q24, Adjusted EBITDA was US$183 million

compared with US$87 million in 3Q23. The main factors that contributed to this increase were (i) higher by-products contribution of US$56

million, mainly due to higher prices and volumes; (ii) the positive net price effect of US$15 million, primarily attributed to higher

zinc prices; (iii) the positive impact of US$13 million from foreign exchange variations; (iv) the positive impact of US$10 million from

lower mineral exploration and project evaluation expenses; and (v) a positive hedge effect of US$4 million. These positive effects were

partially offset by (vi) the negative net impact of US$7 million due to higher costs, mainly from adjustments for Aripuanã’s

idleness in 3Q23, higher reagent consumption due to the processing of new ores in Aripuanã, and higher third-party services in

our Peruvian mines.

| | | |

| |  | 13 |

Compared to 2Q24, Adjusted EBITDA decreased

by 11%. This decrease was primarily driven by (i) the negative net impact of US$40 million in costs, mainly due to adjustments for Aripuanã’s

idleness amounting to US$11 million in 2Q24, which costs are no longer adjusted commencing in 3Q24, and higher third-party services, energy,

and sales expenses in our smelting segment; (ii) lower by-products contribution of US$12 million, attributed to reduced copper and lead

sales volumes and lower prices, partially offset by higher payable values for silver and gold in our Peruvian operations and Aripuanã,

as well as increased copper cement sales volume and higher silver prices in Cajamarquilla. These were partially offset by (iii) a positive

net price effect of US$10 million, mainly in our smelting segment, driven by a positive sales effect from quotation period adjustments;

(iv) higher smelting sales volume of US$8 million, attributed to higher domestic market sales, which improved margins; and (v) the positive

impact of US$7 million from foreign exchange variations.

For 9M24, Adjusted EBITDA was US$517 million

compared to US$296 million for the same period a year ago. This increase was primarily driven by higher by-products contribution, higher

zinc prices, and lower TCs, positively impacting our zinc concentrate purchases. Additionally, lower costs, as well as reduced mineral

exploration and project evaluation expenses contributed to the increase. These positive factors were partially offset by a lower net premium

and lower smelting sales volume in Três Marias and Cajamarquilla.

| | | |

| |  | 14 |

Net Income (Loss) reconciliation

to Adjusted EBITDA

| US$ million |

3Q24 |

2Q24 |

3Q23 |

9M24 |

9M23 |

| Net Income (Loss) |

6.0 |

(70.0) |

(64.5) |

(76.0) |

(183.1) |

| Depreciation and amortization |

82.3 |

74.3 |

75.6 |

233.6 |

223.5 |

| Share in the results of associates |

(5.4) |

(5.3) |

(6.3) |

(16.5) |

(17.4) |

| Net financial results |

41.5 |

118.5 |

66.8 |

227.9 |

133.6 |

| Income tax benefit (expense) |

42.8 |

(23.0) |

0.4 |

19.3 |

(8.1) |

| EBITDA |

167.0 |

94.4 |

72.0 |

388.2 |

148.6 |

| Changes in fair value of offtake agreement (2) |

2.5 |

17.2 |

(1.0) |

21.5 |

(1.0) |

| Impairment loss (reversal) of long-lived assets (3) |

(17.6) |

60.2 |

1.9 |

25.4 |

59.1 |

| Ramp-up expenses of greenfield projects (Aripuanã) (4) |

0.0 |

11.3 |

3.5 |

25.2 |

5.4 |

| Impairment of other assets (5) |

0.0 |

0.0 |

0.0 |

0.3 |

0.0 |

| Loss (gain) on sale and write-off of property, plant and equipment (6) |

6.7 |

0.0 |

(0.1) |

6.9 |

1.2 |

| Remeasurement in estimates of asset retirement obligations (7) |

5.1 |

14.8 |

(2.6) |

22.5 |

(2.8) |

| Remeasurement adjustment of streaming agreement (8) |

21.1 |

0.0 |

2.3 |

21.1 |

2.3 |

| Energy forward contracts – Changes in Fair Value (9) |

(3.6) |

(3.8) |

(2.3) |

(11.8) |

7.4 |

| Tax voluntary disclosure – Value added tax ("VAT") discussions (10) |

0.0 |

0.0 |

12.8 |

0.0 |

76.0 |

| Other restoration obligations (11) |

(0.0) |

(0.2) |

0.0 |

1.1 |

0.0 |

| Divestment and restructuring (12) |

(4.7) |

2.4 |

0.0 |

0.9 |

0.0 |

| Dividends received from associate (13) |

6.5 |

9.7 |

0.0 |

16.2 |

0.0 |

| Adjusted EBITDA (1) |

182.9 |

206.1 |

86.6 |

517.4 |

296.2 |

(1) Adjusted EBITDA excludes the items presented

above in the “Net Income (Loss) reconciliation to Adjusted EBITDA.” For details on segment definition and accounting policy,

please refer to explanatory note 2 – “Information by business segment” in the “Condensed consolidated interim

financial statements at and for the three and nine-month periods ended on September 30, 2024.”

(2) Non-cash adjustment: Derivative financial

instrument related to the “Offtake agreement” described in the section “Others—Offtake agreement” of this

earnings release.

(3) Non-cash adjustment: Cash generating unit

and individual PP&E assets impairment loss (reversal). Please refer to “Others – Impairment” section in this Earnings

Release for further details.

(4) Expenses related to pre-operating and ramp-up

expenses incurred during the commissioning and ramp-up phases of greenfield projects which have not achieved their expected production

capacity. Once the Aripuanã operation is stabilized and operational at its expected production capacity, such effects will no longer

be excluded. Commencing on July 1, 2024, we expect these effects to be no longer included since, at the end of June 2024, it was approaching

the final stage of its ramp-up phase, transitioning to an ongoing operation.

(5) Non-cash adjustment: Value-added-taxes impairment

loss.

(6) Non-cash adjustment: Results from sale and

disposal of certain non-current assets.

(7) Non-cash adjustment: Asset retirement obligation

remeasurement of discount rate and updated studies that are not subject to capitalization.

(8) Non-cash adjustment: Remeasurement of contractual

obligation related to the forward sale contract of Cerro Lindo's Silver contained in the ore.

(9) Non-cash adjustment: The fair value adjustment

of the energy surplus resulting from electric energy purchase contracts of the Company’s subsidiary, Pollarix.

(10) Expenses related to the impact of accruals

related to VAT discussions.

(11) Non-cash adjustment: Expenses related to

the remeasurement of provision related to estimated costs of anticipated additional obligations in relation to certain inactive industrial

waste containment structures in Brazil that have been closed for more than 20 years and that do not contain mining tailings, water or

liquid waste.

(12) Expenses related to the effects of obligations

of restructuring and divestment related to assets held for sale.

(13) Amount in cash dividend received from Enercan,

since the results from these dividends were not consolidated on prior periods.

Net financial

results

The net financial results in 3Q24 were

a loss of US$41 million, significantly lower than the US$118 million loss recorded in 2Q24. This improvement was primarily driven by

foreign exchange gains, and slightly lower financial expenses due to our bonds’ repurchase in 2Q24, partially offset by a slight

reduction in financial income.

| | | |

| |  | 15 |

The foreign

exchange variation had a positive impact of US$11 million in 3Q24 compared to a negative impact of US$64 million in 2Q24, mainly due to

the 2% appreciation of the Brazilian real against the U.S. dollar[4]

in 3Q24.

Excluding the effect of foreign exchange

variations, the net financial results in 3Q24 were a loss of US$52 million compared to an expense of US$55 million in the previous quarter.

| US$ thousand |

3Q24 |

2Q24 |

3Q23 |

| |

|

|

|

| Financial income |

6,206 |

6,775 |

7,802 |

| |

|

|

|

| Financial expenses |

(59,376) |

(62,506) |

(47,233) |

| |

|

|

|

| Other financial items, net |

11,710 |

(62,734) |

(27,400) |

| Foreign exchange gain (loss) |

10,889 |

(63,766) |

(26,882) |

| |

|

|

|

| Net financial result |

(41,460) |

(118,465) |

(66,831) |

| Net financial result excluding FX |

(52,349) |

(54,699) |

(39,949) |

Net Income (Loss)

In 3Q24,

net income amounted to US$6 million compared to a net loss of US$64 million in 3Q23 and US$70 million in 2Q24. The improvement from 2Q24

was primarily driven by foreign exchange gains, higher operating income due to the recognition of an impairment reversal[5],

and lower Other income and expenses[6]

related to changes in the fair value of the offtake agreement, adjustments to asset retirement, restoration,

and environmental obligations, reductions in slow-moving and obsolete inventory, and provisions for legal claims. Additionally, mineral

exploration and project evaluation expenses were lower in the period.

Net Loss attributable to Nexa’s

shareholders was US$5 million in 3Q24, resulting in basic and diluted loss per share attributable to Nexa's shareholders of US$0.04 per

share. In 9M24, Net Loss attributable to Nexa’s shareholders was US$107 million, resulting in basic and diluted loss per share attributable

to Nexa's shareholders of US$0.80.

Excluding miscellaneous adjustments, as

detailed in the Net Income (Loss) reconciliation to Adjusted EBITDA section, adjusted net income was US$22 million for the quarter, totaling

US$53 million in 9M24.

Adjusted Net Income attributable to Nexa’s

shareholders was US$2.4 million in 3Q24, resulting in adjusted earnings per share of US$0.02. In 9M24, Adjusted Net Income attributable

to Nexa’s shareholders was US$0.4 million, resulting in adjusted earnings per share of US$0.00.

[4]

In 3Q24, the Brazilian real / U.S. dollar (end of period) exchange rate was R$5.448/US$1.00 compared to R$5.559/US$1.00 in 2Q24.

[5]

For more information, please refer to explanatory note 19 – “Impairment of long-lived assets”

in the “Condensed consolidated interim financial statements at and for the three and nine-month periods ended on September 30, 2024.”

[6]

For more information, please refer to explanatory notes 10 (e) – “Financial instruments in the

offtake agreement: fair value” and 17 (ii) – “Changes in asset retirement, restoration and environmental obligations”

in the “Condensed consolidated interim financial statements at and for the three and nine-month periods ended on September 30, 2024.”

| | | |

| |  | 16 |

US$ million

(except where otherwise indicated) |

3Q24 |

2Q24 |

3Q23 |

9M24 |

9M23 |

| Net Income (loss) |

6.0 |

(70.0) |

(64.5) |

(76.0) |

(183.1) |

| Attributable to Nexa's shareholders |

(5.2) |

(77.0) |

(74.9) |

(106.5) |

(197.4) |

| Attributable to non-controlling interests |

11.1 |

7.0 |

10.4 |

30.5 |

14.4 |

| Basic and diluted loss per share |

(0.04) |

(0.58) |

(0.57) |

(0.80) |

(1.49) |

| |

|

|

|

|

|

| Miscellaneous adjustments (1) |

15.9 |

111.6 |

14.6 |

129.2 |

147.6 |

| Attributable to Nexa's shareholders |

8.7 |

95.9 |

16.6 |

108.2 |

143.3 |

| Attributable to non-controlling interests |

7.1 |

15.7 |

(2.0) |

21.0 |

4.3 |

| Basic and diluted miscellaneous adjustments per share |

0.07 |

0.72 |

0.13 |

0.82 |

1.08 |

| |

|

|

|

|

|

| Adjusted net income (loss) |

21.9 |

41.7 |

(49.9) |

53.2 |

(35.4) |

| Attributable to Nexa's shareholders |

2.4 |

18.9 |

(58.3) |

0.4 |

(54.1) |

| Attributable to non-controlling interests |

19.5 |

22.8 |

8.4 |

52.8 |

18.7 |

| Weighted average number of outstanding shares - in thousand |

132,439 |

132,439 |

132,439 |

132,439 |

132,439 |

| Adjusted basic and diluted earnings (loss) per share |

0.02 |

0.14 |

(0.44) |

0.00 |

(0.41) |

(1) Miscellaneous adjustments include: (i)

Changes in fair value of the offtake agreement; (ii) Impairment loss (reversal) of long-lived assets; (iii) Ramp-up expenses of greenfield

projects (Aripuanã); (iv) Impairment of other assets; (v) Loss on sale of property, plant and equipment; (vi) Remeasurement in

estimates of asset retirement obligations; (vii) Remeasurement adjustment of streaming agreement; (viii) Changes in fair value of energy

forward contracts; (ix) Tax voluntary disclosure – VAT discussions; (x) Other restoration obligations; (xi) Divestment and restructuring;

and (x) Cash dividend received from Enercan.

| | | |

| |  | 17 |

Business Performance

Mining segment

| Consolidated |

|

3Q24 |

2Q24 |

3Q23 |

3Q24 vs. 3Q23 |

9M24 |

9M23 |

9M24 vs. 9M23 |

| Ore Mined |

kt |

3,426 |

3,216 |

3,284 |

4.3% |

9,904 |

9,437 |

5.0% |

| Treated Ore |

kt |

3,381 |

3,281 |

3,470 |

(2.6%) |

10,055 |

10,147 |

(0.9%) |

| |

|

|

|

|

|

|

|

|

| Grade |

|

|

|

|

|

|

|

|

| Zinc |

% |

2.90 |

2.99 |

3.03 |

(13 bps) |

2.97 |

2.90 |

7 bps |

| Copper |

% |

0.36 |

0.38 |

0.37 |

(1 bps) |

0.35 |

0.33 |

2 bps |

| Lead |

% |

0.65 |

0.65 |

0.67 |

(2 bps) |

0.67 |

0.67 |

(1 bps) |

| Silver |

oz/t |

1.14 |

1.12 |

1.01 |

12.9% |

1.14 |

1.02 |

11.3% |

| Gold |

oz/t |

0.006 |

0.006 |

0.005 |

19.1% |

0.006 |

0.005 |

16.0% |

| |

|

|

|

|

|

|

|

|

| Production | metal contained |

|

|

|

|

|

|

|

| Zinc |

kt |

82.7 |

82.5 |

87.4 |

(5.4%) |

252.5 |

242.9 |

3.9% |

| Copper |

kt |

9.3 |

9.7 |

9.3 |

0.6% |

26.6 |

24.0 |

10.6% |

| Lead |

kt |

17.0 |

16.7 |

16.5 |

3.3% |

52.0 |

47.6 |

9.1% |

| Silver |

MMoz |

2.9 |

2.8 |

2.6 |

13.9% |

8.7 |

7.6 |

15.6% |

| Gold |

koz |

9.3 |

8.6 |

6.6 |

41.3% |

26.6 |

19.9 |

33.3% |

| Zinc Equivalent (1) |

kt |

158.9 |

159.1 |

160.8 |

(1.2%) |

477.0 |

445.7 |

7.0% |

(1) Consolidated mining production in kt

of zinc equivalent is calculated by converting copper, lead, silver, and gold contents to a zinc equivalent grade, assuming 2023 LME average

prices: Zn: US$1.20/lb; Cu: US$3.85/lb; Pb: US$0.97/lb; Ag: US$23.4/oz; Au: US$1,943/oz.

In 3Q24, treated ore volume reached 3,381kt,

reflecting a 3% year-over-year decrease, primarily due to the cessation of operations at Morro Agudo following its sale, which impacted

overall performance, partially offset by higher plant performance across all mines, except for El Porvenir.

Compared to 2Q24, treated ore volume increased

by 3%, driven by positive performance from all mines, although still impacted by the absence of contributions from Morro Agudo.

The ore throughput, year-over-year, increased

at Atacocha (+37%), Aripuanã (+30%), Vazante (+5%), and Cerro Lindo (+1%). Conversely, El Porvenir slightly decreased by (-1%).

Overall treated ore throughput was affected by the absence of contributions from Morro Agudo.

Zinc equivalent production totaled 159kt

in 3Q24, remaining relatively flat compared to 3Q23. The average head grades for zinc, copper, and lead decreased by 13bps to 2.90%, 1bps

to 0.36%, and 2bps to 0.65%, respectively, while silver head grades increased by 13% to 1.14oz/t. Compared to 2Q24, zinc equivalent production

was also relatively flat.

Zinc production of 83kt in the quarter

decreased by 5% from 3Q23, mainly due to lower average head grades at Vazante and El Porvenir, and the absence of contributions from Morro

Agudo, partially offset by higher volumes from Aripuanã. Compared to 2Q24, zinc production was relatively flat, with higher volumes

from Vazante, El Porvenir and Atacocha, offset by the absence of contributions from Morro Agudo and slightly lower volumes from Cerro

Lindo and Aripuanã.

Copper production of 9kt remained flat

compared to 3Q23. Compared to 2Q24, copper production decreased by 4%, primarily driven by a lower contribution from Cerro Lindo.

| | | |

| |  | 18 |

Lead production increased by 3% year-over-year,

mainly explained by higher contributions from Atacocha and Aripuanã, and increased by 2% quarter-over-quarter, driven by higher

contributions from Atacocha and Cerro Lindo, despite the absence of contributions from Morro Agudo in the period.

In 9M24, treated ore volume was slightly

lower year-over-year, totaling 10,055kt. Zinc average grade was up 7bps to 2.97%. Therefore, zinc production totaled 252kt, 4% higher

than in 9M23. Copper production of 27kt was 11% higher and lead production increased by 9% to 52kt.

Cerro Lindo

Cerro Lindo

(100% basis) |

|

3Q24 |

2Q24 |

1Q24 |

9M24 |

4Q23 |

3Q23 |

2Q23 |

1Q23 |

9M23 |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Ore Mined |

kt |

1,593 |

1,484 |

1,457 |

4,534 |

1,617 |

1,515 |

1,595 |

1,254 |

4,365 |

|

| Treated Ore |

kt |

1,560 |

1,472 |

1,471 |

4,503 |

1,644 |

1,540 |

1,530 |

1,277 |

4,347 |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Grade |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Zinc |

% |

1.67 |

1.86 |

1.87 |

1.80 |

1.70 |

1.63 |

1.31 |

1.38 |

1.44 |

|

| Copper |

% |

0.56 |

0.66 |

0.51 |

0.58 |

0.58 |

0.63 |

0.57 |

0.48 |

0.57 |

|

| Lead |

% |

0.30 |

0.31 |

0.44 |

0.35 |

0.32 |

0.32 |

0.33 |

0.25 |

0.30 |

|

| Silver |

oz/t |

0.89 |

0.92 |

1.14 |

0.98 |

0.83 |

0.81 |

0.83 |

0.72 |

0.79 |

|

| Gold |

oz/t |

0.003 |

0.002 |

0.003 |

0.003 |

0.003 |

0.002 |

0.002 |

0.002 |

0.002 |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Production | metal contained |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Zinc |

kt |

23.1 |

24.1 |

24.3 |

71.5 |

24.6 |

21.7 |

16.9 |

15.0 |

53.6 |

|

| Copper |

kt |

7.5 |

8.4 |

5.9 |

21.8 |

7.9 |

8.1 |

7.4 |

5.2 |

20.7 |

|

| Lead |

kt |

3.7 |

3.3 |

4.9 |

11.9 |

3.8 |

3.6 |

3.6 |

2.1 |

9.3 |

|

| Silver |

MMoz |

1.1 |

1.0 |

1.3 |

3.4 |

1.0 |

0.9 |

0.9 |

0.6 |

2.5 |

|

| Gold |

koz |

1.3 |

1.0 |

1.2 |

3.5 |

1.2 |

0.7 |

0.8 |

0.7 |

2.2 |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Zinc sales |

kt |

24.1 |

24.4 |

22.8 |

71.3 |

25.3 |

20.8 |

17.5 |

14.8 |

53.1 |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Costs |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Cost of sales |

US$ mm |

88.5 |

92.9 |

84.9 |

266.2 |

98.1 |

88.6 |

86.5 |

81.6 |

256.7 |

|

| Cost ROM (2) |

US$/t |

40.6 |

45.8 |

41.6 |

42.6 |

41.5 |

41.3 |

39.8 |

39.6 |

40.3 |

|

| Cash cost (1) |

US$/lb |

(0.36) |

(0.58) |

(0.23) |

(0.39) |

0.06 |

(0.18) |

(0.13) |

(0.02) |

(0.12) |

|

| Sustaining cash cost (1) |

US$/lb |

(0.15) |

(0.36) |

(0.06) |

(0.20) |

0.29 |

0.07 |

0.15 |

0.23 |

0.14 |

|

| |

|

|

|

|

|

|

|

|

|

|

|

| CAPEX |

US$ mm |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Sustaining |

|

11.0 |

11.5 |

8.5 |

30.9 |

11.2 |

9.1 |

9.4 |

8.0 |

26.5 |

|

| Other |

|

0.2 |

0.1 |

0.0 |

0.2 |

1.7 |

2.0 |

1.5 |

0.4 |

3.9 |

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1) Our cash cost and sustaining cash cost

are net of by-products credits, measured with respect to zinc sold per mine. For a cash cost reconciliation to COGS, please refer to Appendix

– All in Sustaining Cash Cost | Mining.

(2) Our cost per ROM is measured with respect

to treated ore volume. Refer to “Use of Non-IFRS Financial Measures” for further information.

In 3Q24, treated ore volume was 1,560kt,

up by 1% and 6% year-over-year and quarter-over-quarter, respectively.

| | | |

| |  | 19 |

Zinc production of 23kt increased by 7%

compared to 3Q23, primarily driven by the prioritization of areas with higher zinc grades, in line with the mine sequencing plan. Compared

to 2Q24, zinc production decreased by 4%, due to mine development and rehabilitation activities in areas with lower zinc grades in the

period.

The average zinc head grade for the quarter

was 1.67%, up 4bps and down 19bps compared to 3Q23 and 2Q24, respectively.

Copper production totaled 7.5kt, down

8% year-over-year and 10% quarter-over-quarter, attributed to operations in areas with lower copper grades. The average copper grade was

0.56% in 3Q24, compared to 0.63% in 3Q23 and 0.66% in 2Q24.

Lead production reached 3.7kt, slightly

up from 3.6kt in 3Q23 and 3.3kt in 2Q24, despite lower average lead grade in the period, which decreased by 1bps both year-over-year and

quarter-over-quarter.

In the first nine months of 2024, zinc

production totaled 71kt, up 33% compared to 9M23, mainly driven by higher zinc grades and higher treated ore volumes. Copper production

rose by 5% to 22kt, while lead production increased by 28% to 12kt, both attributed to higher average grades.

Cost

Cost of sales was US$88 million in 3Q24

compared to US$89 million in the same period last year. This slight decrease was primarily due to lower third-party services expenses,

partially offset by higher maintenance costs. Compared to 2Q24, cost of sales decreased by 5%, mainly driven by lower third-party services

and maintenance costs, partially offset by higher variable costs associated with royalties, freights expenses, and an increase in personnel

costs.

Run-of-mine mining cost was US$41/t in

the quarter, down 2% year-over-year, mainly explained by lower variable costs and higher treated ore volumes. Compared to 2Q24, run-of-mine

mining cost decreased by 11% due to higher treated ore volumes, lower maintenance expenses, and reductions in third-party services and

variable costs.

Cash cost net of by-products in 3Q24 decreased

to US$(0.36)/lb compared with US$(0.18)/lb in 3Q23 but increased compared with US$(0.58)/lb in 2Q24. The year-over-year improvement was

mainly due to lower TCs, and higher by-products contribution supported by higher LME metal prices (except lead). The quarter-over-quarter

increase was mainly attributed to a lower contribution from by-products, mainly driven by decreased copper volumes and prices, as well

as lower zinc volumes, which were partially offset by lower operational costs.

CAPEX

In 3Q24, sustaining capital expenditures

amounted to US$11 million, primarily allocated to mine development, maintenance, and equipment acquisition, totaling US$31 million in

9M24.

| | | |

| |  | 20 |

El Porvenir

El Porvenir

(100% basis) |

|

3Q24 |

2Q24 |

1Q24 |

9M24 |

4Q23 |

3Q23 |

2Q23 |

1Q23 |

9M23 |

| |

|

|

|

|

|

|

|

|

|

|

| Ore Mined |

kt |

571 |

538 |

530 |

1,638 |

562 |

568 |

546 |

544 |

1,658 |

| Treated Ore |

kt |

564 |

538 |

530 |

1,631 |

562 |

568 |

546 |

544 |

1,658 |

| |

|

|

|

|

|

|

|

|

|

|

| Grade |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| Zinc |

% |

2.58 |

2.56 |

2.76 |

2.63 |

2.83 |

2.89 |

2.89 |

2.82 |

2.87 |

| Copper |

% |

0.14 |

0.14 |

0.16 |

0.15 |

0.16 |

0.16 |

0.17 |

0.15 |

0.16 |

| Lead |

% |

1.35 |

1.41 |

1.48 |

1.41 |

1.39 |

1.36 |

1.35 |

1.38 |

1.36 |

| Silver |

oz/t |

2.34 |

2.42 |

2.47 |

2.41 |

2.20 |

2.22 |

2.42 |

2.55 |

2.39 |

| Gold |

oz/t |

0.009 |

0.009 |

0.011 |

0.010 |

0.010 |

0.010 |

0.011 |

0.011 |

0.011 |

| |

|

|

|

|

|

|

|

|

|

|

| Production | metal contained |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| Zinc |