Laser Photonics Expands Semiconductor Industry-Focused Product Line

03 December 2024 - 11:00PM

Business Wire

Laser Photonics Corporation (NASDAQ: LASE) (“LPC” or “the

Company”), a leading global developer of industrial laser systems

for cleaning and other material processing applications, announced

today the expansion of its product offering targeting the surging

market for chip fabrication.

The growing demand for electronics and electric vehicles, the

rise of industrial automation, and the adoption of AI by

technologies across all areas are just some factors that are

propelling the chip design and fabrication market forward. Indeed,

some analysts expect the semiconductor market to reach an annual $1

trillion by 2030 on the global scale. Yet, although global supply

chains have largely recovered from the COVID-19 pandemic,

challenges persist as they struggle to fulfill the high demand for

advanced chips. That is why the adoption of high-speed laser

processing equipment by chip fabs is more essential than ever.

LPC is providing this laser-powered technology to help

accelerate the manufacturing of semiconductors. For the Company,

established as a trusted provider of industrial laser equipment for

surface preparation, cutting, marking, and welding, chip

fabrication has been one of the target sectors. Now, joined by its

recently acquired subsidiary, Control Micro Systems, Inc. (CMS),

LPC has expanded its product line of advanced laser wafer dicing,

marking, and scribing technologies.

One of LPC’s flagship products in this space is the BlackStar

laser wafer dicing and scribing system. Engineered with short-pulse

laser technology, die singulation by the BlackStar involves minimal

heat and does not require water jet cooling to separate brittle

materials like silicon. This technique greatly improves die yield

while minimizing the need for individual die processing, in turn

reducing time and labor.

LPC’s expanded portfolio of products for the semiconductor

industry now also includes custom-tailored multi-station laser

systems for wafer marking, scribing, and lapping, built to handle a

variety of wafer thicknesses and sizes. This innovative technology

features robotic wafer positioning and machine vision, and serves

to facilitate the production and tracing of chips. Separately, a

chip marking system integrating ultraviolet laser technology has

been added to its portfolio, which allows for the production of the

smallest permanent chip markings without damage to the surrounding

microstructure of the die.

“Our growth is fueled by the addition of CMS, and we are excited

to expand our product portfolio and offer high-speed, effective

laser equipment to chip fabs,” said Wayne Tupuola, CEO of LPC. “We

are continuously driven by our mission to upgrade industrial

material processing with reliable laser technology. For the

semiconductor manufacturing sector, where progress is critical

today, we provide automated solutions that greatly optimize the

processing of silicon and related brittle materials.”

For more information, visit the LPC website at

www.laserphotonics.com.

About Laser Photonics Corporation

Laser Photonics is a vertically integrated manufacturer and

R&D Center of Excellence for industrial laser technologies and

systems. Laser Photonics seeks to disrupt the $46 billion,

centuries-old sand and abrasives blasting markets, focusing on

surface cleaning, rust removal, corrosion control, de-painting and

other laser-based industrial applications. Laser Photonics’ new

generation of leading-edge laser blasting technologies and

equipment also addresses the numerous health, safety, environmental

and regulatory issues associated with old methods. As a result,

Laser Photonics has quickly gained a reputation as an industry

leader in industrial laser systems with a brand that stands for

quality, technology and product innovation. Currently,

world-renowned and Fortune 1000 manufacturers in the aerospace,

automotive, defense, energy, maritime, nuclear and space industries

are using Laser Photonics’ “unique-to-industry” systems. For more

information, visit https://www.laserphotonics.com.

Cautionary Note Concerning Forward-Looking Statements

This press release contains “forward-looking statements” (within

the meaning of Section 27A of the Securities Act of 1933, as

amended, and Section 21E of the Securities Exchange Act of 1934, as

amended), including statements regarding the Company’s plans,

prospects, potential results and use of proceeds. These statements

are based on current expectations as of the date of this press

release and involve a number of risks and uncertainties, which may

cause results and uses of proceeds to differ materially from those

indicated by these forward-looking statements. These risks include,

without limitation, those described under the caption “Risk

Factors” in the Registration Statement. Any reader of this press

release is cautioned not to place undue reliance on these

forward-looking statements, which speak only as of the date of this

press release. The Company undertakes no obligation to revise or

update any forward-looking statements to reflect events or

circumstances after the date of this press release except as

required by applicable laws or regulations.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20241203029095/en/

Media: Karla Kizzort Marketing Specialist Laser Photonics

Corporation kkizzort@laserphotonics.com

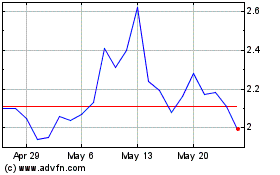

Laser Photonics (NASDAQ:LASE)

Historical Stock Chart

From Dec 2024 to Jan 2025

Laser Photonics (NASDAQ:LASE)

Historical Stock Chart

From Jan 2024 to Jan 2025