HPQ Silicon Inc. (“HPQ” or the “Company”) (TSX-V: HPQ,

OTCQB: HPQFF, FRA: O08), a technology company

specializing in green engineering of silica and silicon-based

materials would like to update shareholders on recent developments

from HPQ Silica Polvere Inc. (“HSPI”) [1] regarding the commercial

validation of its proprietary Fumed Silica Reactor (FSR) process.

Technology supplier PyroGenesis Canada Inc. (TSX: PYR,

OTCQX: PYRGF, FRA: 8PY) (“PyroGenesis”) informed HSPI

that, after successfully commissioning the pilot system, its

engineering team identified the need for an additional enhancement

to improve the performance of the pilot plant. This enhancement

will ensure a more consistent flow of fumed silica from the reactor

to downstream recovery equipment at pilot scale, a marked

improvement from its lab-scale system.

“Implementing the enhancement at this stage is essential for a

smooth transition to commercial production later on,” said P. Peter

Pascali, President and CEO of PyroGenesis Inc. “By refining the

operational process now, we’re ensuring that HSPI’s clients can

expect high-quality standards, setting the stage for a sustainable

and efficient production scale-up.”

Ensuring Product Quality with Key Process

Enhancements

PyroGenesis Canada is always actively exploring ways to refine

HSPI’s proprietary FSR technology pilot plant to ensure

high-quality production at both the pilot scale and in future

commercial operations. The current improvement centers on an

extended refractory conditioning phase, a crucial process designed

to prepare the reactor’s internal structure to handle continuous,

high-quality material output. Before full material production

begins, the refractory lining within the reactor must undergo

high-temperature curing, a step that conditions and strengthens the

lining, especially in areas exposed to off-gas interactions.

This conditioning is essential to creating a smoother, more

robust inner surface that can withstand prolonged high-intensity

use. By establishing these foundational elements now, we are

setting up the pilot plant for steady, high-efficiency operation

that will meet quality standards both during pilot runs and in

commercial-scale production.

“Implementing this integration, which ensures a consistent flow

of product at this stage, demonstrates that the PyroGenesis

engineering team has complete control over the process,” added Mr.

Pascali.

“These normal and expected process improvements during the

scale-up phase do not alter our confidence in the transformative

potential of our FSR technology,” said Bernard Tourillon, President

& CEO of HPQ Silicon and HPQ Silicon Polvere. “Our objective

remains clear: to disrupt the fumed silica market by providing a

cost-effective, high-efficiency solution that could redefine

industry standards. We are making strides toward securing offtake

agreements and are excited to lead the charge in revolutionizing

fumed silica manufacturing.”

A Foundation for Commercial Readiness

Once the extended refractory conditioning phase is completed in

the next two weeks, the program will advance to the batch

production phase, during which the FSR will begin manufacturing

fumed silica. The primary objective at this stage is to validate

the process’s ability to consistently replicate essential physical

properties—such as surface area—and rheological properties,

including viscosity and thickening behavior, as demonstrated at the

lab scale. After reaching this milestone, the system will

transition to semi-continuous operation, targeting the production

of at least 200 kg of commercial-grade fumed silica samples for

comprehensive testing and validation.

Throughout these phases, the produced fumed silica will undergo

internal testing, with samples sent to Evonik as per the LOI

announced on July 9, 2024, and potentially to other parties under

NDA for evaluation. By Q1 2025, the focus will shift toward

optimizing pilot plant operations to produce food- and pharma-grade

fumed silica with surface areas of 300 m²/g. In addition to

producing materials with surface areas ranging from 150 to 300

m²/g, the overarching goal is to run the pilot plant at full

capacity, achieving multiple daily production cycles and delivering

commercial-quality material. With an estimated 20 hours of daily

operation, the system is projected to produce approximately 161 kg

per day, or 50,000 kg annually (50 TPY).

REFERENCE SOURCES

|

[1] |

A

wholly owned subsidiary of HPQ Silicon Inc. when technology

supplier PyroGenesis announced its intention to exercise its option

to acquire a 50% stake in HSPI in May 2024. |

About HPQ

HPQ Silicon Inc. (TSX-V: HPQ) is a

Quebec-based TSX Venture Exchange Tier 1 Industrial Issuer.

HPQ is developing, with the support of

world-class technology partners PyroGenesis Canada Inc. and

NOVACIUM SAS, new green processes crucial to make the critical

materials needed to reach net zero emissions.

HPQ activities are centred around the following

four (4) pillars:

|

|

1) |

Becoming a green low-cost (Capex and Opex) manufacturer of Fumed

Silica using the FUMED SILICA REACTOR, a

proprietary technology owned by HPQ Silica Polvere Inc being

developed for HSPI by PyroGenesis. |

| |

2) |

Becoming a producer of

silicon-based anode materials for battery applications with the

assistance of NOVACIUM SAS. |

| |

3) |

HPQ SILICON affiliate NOVACIUM

SAS is developing a low carbon, chemical base on demand and

high-pressure autonomous hydrogen production system. |

| |

4) |

Becoming a zero CO2 low-cost

(Capex and Opex) producer of High Purity Silicon (2N+ to 4N) using

our PUREVAPTM “Quartz

Reduction Reactors” (QRR), a proprietary technology owned

by HPQ being developed for HPQ by PyroGenesis. |

For more information, please visit HPQ Silicon

web site.

About PyroGenesis Canada Inc.

PyroGenesis Canada Inc., a high-tech company, is

a leader in the design, development, manufacture and

commercialization of advanced plasma processes and sustainable

solutions which reduce greenhouse gases (GHG) and are economically

attractive alternatives to conventional “dirty” processes.

PyroGenesis has created proprietary, patented, and advanced plasma

technologies that are being vetted and adopted by multiple

multibillion dollar industry leaders in three massive markets: iron

ore pelletization, aluminum, waste management, and additive

manufacturing. With a team of experienced engineers, scientists and

technicians working out of its Montreal office, and its 3,800 m2

and 2,940 m2 R&D and manufacturing facilities, PyroGenesis

maintains its competitive advantage by remaining at the forefront

of technology development and commercialization. The operations are

ISO 9001:2015 and AS9100D certified, having been ISO certified

since 1997. For more information, please visit:

www.pyrogenesis.com

Disclaimers:

This press release contains certain

forward-looking statements, including, without limitation,

statements containing the words "may", "plan", "will", "estimate",

"continue", "anticipate", "intend", "expect", "in the process" and

other similar expressions which constitute "forward-looking

information" within the meaning of applicable securities laws.

Forward-looking statements reflect the Company's current

expectation and assumptions and are subject to a number of risks

and uncertainties that could cause actual results to differ

materially from those anticipated. These forward-looking statements

involve risks and uncertainties including, but not limited to, our

expectations regarding the acceptance of our products by the

market, our strategy to develop new products and enhance the

capabilities of existing products, our strategy with respect to

research and development, the impact of competitive products and

pricing, new product development, and uncertainties related to the

regulatory approval process. Such statements reflect the current

views of the Company with respect to future events and are subject

to certain risks and uncertainties and other risks detailed from

time-to-time in the Company's ongoing filings with the security’s

regulatory authorities, which filings can be found at

www.sedar.com. Actual results, events, and performance may differ

materially. Readers are cautioned not to place undue reliance on

these forward-looking statements. The Company undertakes no

obligation to publicly update or revise any forward-looking

statements either as a result of new information, future events or

otherwise, except as required by applicable securities laws.

Neither the TSX Venture Exchange nor its

Regulation Services Provider (as that term is defined in the

policies of the TSX Venture Exchange) accepts responsibility for

the adequacy or accuracy of this release.

This News Release is available on the

company's CEO Verified Discussion Forum, a moderated social

media platform that enables civilized discussion and Q&A

between Management and Shareholders.

Source: HPQ Silicon Inc.For further

information contact: Bernard J. Tourillon, Chairman,

President, and CEO Tel +1 (514) 846-3271Patrick Levasseur, Director

Tel: +1 (514) 262-9239Email: Info@hpqsilicon.com

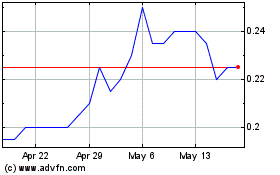

HPQ Silicon (TSXV:HPQ)

Historical Stock Chart

From Nov 2024 to Dec 2024

HPQ Silicon (TSXV:HPQ)

Historical Stock Chart

From Dec 2023 to Dec 2024