Laser Photonics Corporation (LPC) (NASDAQ: LASE), a leading

global industrial developer of systems for laser cutting, marking

and other material applications, announced today that it will

attend the International Electron Devices Meeting 2024 to present

advanced laser solutions for the semiconductor industry.

IEDM 2024, hosted by the Institute of Electrical and Electronics

Engineers (IEEE) and the Electron Devices Society, is the premier

global forum for breakthroughs in semiconductor and electronic

device technology. It gathers industry leaders, engineers, and

scientists from around the world to discuss advancements in

semiconductor design and manufacturing, optoelectronics, nanoscale

devices, simulation, and more. This year marks the 70th annual IEEE

IEDM.

Wayne Tupuola, CEO of LPC, stated, “For Laser Photonics, IEDM is

an excellent platform to present our state-of-the-art solutions for

dicing and marking of silicon, sapphire and compounds. We are

excited to relay how quickly and accurately laser technology can

process brittle crystalline materials used in semiconductors, solar

panels, and related products.”

Visitors to LPC’s booth at IEDM 2024 can learn about the

BlackStar Laser Wafer Dicer engineered for optimal die singulation;

the High-Precision Wafer Serialization, Marking and Scribing laser

solution for traceability, scribing and lapping; and the Laser

Marking of IC Mold Compounds system with high-speed fiducial

recognition for marking the smallest parts without any risk of

damage.

What: 70th Annual IEEE International Electron Devices

Meeting

When: December 7 - 11, 2024

Where: Booth 3, Yosemite Ballroom, Hilton San

Francisco

Union Square, 333 O’Farrell Street, San

Francisco, CA

About BlackStar Laser Wafer Dicer

Powered by Fantom Width Laser Dicing (FWLD) technology, the

BlackStar helps maximize die yield per wafer and minimize material

loss. Equipped with a short-pulse laser, this technology addresses

silicon dicing challenges like impact damage and thermal

distortions. The BlackStar offers versatility in processing various

die sizes, while the dry processing technique eliminates water use

and extra handling, with no replacement parts or regular

maintenance needed. The BlackStar is a Class I enclosed laser

system equipped with safe viewing windows that prevent accidental

exposure to laser radiation, interlocks to deactivate the laser in

open mode, key control, and other safety features.

About High-Precision Wafer Serialization, Marking and

Scribing

This next-generation laser system for optimized wafer

traceability is custom-tailored specifically for your requirements,

including the geometries, dimensions, line width, slag tolerances,

safety features and cleanroom protocols. This system processes

silicon, sapphire, compounds (GaAS, InP, SiCO2, SiGe, etc.),

crystal wafers (LiTaO3 and LiNbO3) or photo resist. It is built to

accommodate a range of wafer sizes and thicknesses and features a

dual end effector robot for wafer movement. Laser type will depend

on wafer material and marking requirements.

About Laser Marking of IC Mold Compounds

These systems use state-of-the-art machine vision that travels

through a laser scanhead to achieve high-speed fiducial

recognition. This allows to mark characters at sizes precisely in

accordance with user requirements, with no damage risk down to even

the smallest parts. This enclosed Class I system integrates an

ultraviolet laser and is configured to accept JEDEC trays with

small-scale computer chips, using the sophisticated vision system

for perfect alignment with their positioning. Non-contact laser

marking requires no consumables or additives to generate permanent,

high-contrast markings, data matrices, logos, shapes, and text on

IC mold compounds and ceramics.

About Laser Photonics Corporation

Laser Photonics is a vertically integrated manufacturer and

R&D Center of Excellence for industrial laser technologies and

systems. Laser Photonics seeks to disrupt the $46 billion,

centuries-old sand and abrasives blasting markets, focusing on

surface cleaning, rust removal, corrosion control, de-painting and

other laser-based industrial applications. Laser Photonics’ new

generation of leading-edge laser blasting technologies and

equipment also addresses the numerous health, safety, environmental

and regulatory issues associated with old methods. As a result,

Laser Photonics has quickly gained a reputation as a leader in

industrial laser systems with a brand that stands for quality,

technology and product innovation. Currently, world-renowned and

Fortune 1000 manufacturers in the aerospace, automotive, defense,

energy, maritime, medical device, nuclear and pharmaceutical, and

space industries are using Laser Photonics’ “unique-to-industry”

systems. For more information, visit

https://www.laserphotonics.com.

About IEEE

IEEE is the world’s largest technical professional organization

dedicated to advancing technology for the benefit of humanity.

Through its highly cited publications, conferences, technology

standards, and professional and educational activities, IEEE is the

trusted voice in a wide variety of areas ranging from aerospace

systems, computers, and telecommunications to biomedical

engineering, electric power, and consumer electronics. Learn more

at https://www.ieee.org.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20241122847290/en/

Karla Kizzort Marketing Specialist Laser Photonics Corporation

kkizzort@laserphotonics.com

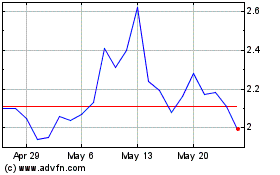

Laser Photonics (NASDAQ:LASE)

Historical Stock Chart

From Nov 2024 to Dec 2024

Laser Photonics (NASDAQ:LASE)

Historical Stock Chart

From Dec 2023 to Dec 2024