Stratasys unveils the DentaJet™ XL solution, designed to transform production of high-quality models for crowns and bridges, implants, clear aligner arches, and surgical guides

11 July 2024 - 10:15PM

Business Wire

Unprecedented Efficiency for High-volume Dental

Labs Made Possible for Printing at Scale, Reducing Cost-per-part by

Up to 67%

Stratasys Ltd. (NASDAQ: SSYS), announced today the launch of the

groundbreaking DentaJet™ XL, the latest innovation in dental 3D

printing technology. This new high-speed 3D printer is the latest

addition to the DentaJet series, designed to further improve dental

lab productivity and reduce costs with its larger resin cartridges,

large print tray, Super High-Speed mode, and minimal post

processing workflow.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20240711185837/en/

The new Stratasys DentaJet XL Printer for

high-volume dental labs, cutting labor costs and time needed for

printing. (Photo: Business Wire)

"The Stratasys DentaJet XL solution is engineered specifically

for digital dental labs that must deliver high volumes of

applications without sacrificing quality, helping them overcome

significant challenges in finding and retaining qualified

technicians as they work to meet growing market demand,” said Ronen

Lebi, Vice President, Stratasys Dental. “It is the most efficient

production solution we have developed to date, geared to produce

highly accurate crown and bridge, implant, and aligner models and

surgical guides simultaneously at scale."

The new PolyJet™ multi-material 3D printer is designed to run in

a production setting with minimal human intervention. With advanced

software print prep and print management features, as well as

unattended printing and curing, labs can reduce up to 90 percent of

their labor costs. The introduction of new printing modes and

larger cartridges results in up to 67% lower cost per part. This

new printer can be integrated with new validated, fast and large

batch post processing workflows for support removal. It also allows

for printing two materials simultaneously. And it can improve lab

productivity and lowers costs making it the “go-to” solution for

large volume production labs around the world.

"Incorporating the DentaJet XL 3D printer into our laboratory

has significantly improved our digital workflow,” said James

Dobson, Vice President, Digital Production, Dobson Ortho

Laboratories and one of the first to implement the solution. “With

its large print tray, 4X larger resin cartridges, and hot-swap

capabilities, we have already achieved significant material and

labor savings. Creating print jobs has become extremely fast and

simple with the automatic part nesting features. Furthermore, its

sealed resin system ensures a healthier workplace for our

team."

"The new Super High-Speed Mode allowed us to significantly

increase our production of clear aligners by nearly 50%, without

adding any additional labor and at a much-reduced cost per part,”

said Prof. Armando Razionale, Airnivol, and one of the first

customers implementing the solution in Europe. “Plus, by

integrating the DentaJet XL with the automatic support removal

workflow, we are saving a tremendous amount of time and labor in

the final stage of production. It’s almost like we added a virtual

lab technician!"

The first DentaJet XL customers were able to achieve notable

production results:

- Up to 16 implant cases (surgical guide and model) in 6 hours 30

minutes

- Up to 102 crown & bridge models in 4 hours 31 minutes

- Up to 28 orthodontic models in 6 hours 37 minutes

- Up to 36 aligner arches in 2 hours 14 minutes

Notable features of this new solution include:

- Uninterrupted printing, even for the largest jobs with 4kg

resin cartridges and hot-swap.

- Significantly reduced print prep times and integrated fleet

management with intuitive GrabCAD Print software.

- Increased production speed of clear aligner arches by up to 30

percent with a super high-speed mode.

- Dual-material printing, which allows labs to increase output by

printing two materials at once.

- Efficient post-processing with integrated third-party workflows

for large batch support removal. This streamlines processes and

saves time and labor.

For more information on the DentaJet XL and to schedule a demo,

please visit www.stratasys.com/dentajet-xl.

About Stratasys

Stratasys is leading the global shift to additive manufacturing

with innovative 3D printing solutions for industries such as

aerospace, automotive, consumer products and healthcare. Through

smart and connected 3D printers, polymer materials, a software

ecosystem, and parts on demand, Stratasys solutions deliver

competitive advantages at every stage in the product value chain.

The world’s leading organizations turn to Stratasys to transform

product design, bring agility to manufacturing and supply chains,

and improve patient care.

To learn more about Stratasys, visit www.stratasys.com, the

Stratasys blog, X/Twitter, LinkedIn, or Facebook. Stratasys

reserves the right to utilize any of the foregoing social media

platforms, including Stratasys’ websites, to share material

non-public information pursuant to the SEC’s Regulation FD. To the

extent necessary and mandated by applicable law, Stratasys will

also include such information in its public disclosure filings.

Stratasys, DentaJet, PolyJet and GrabCAD Print are trademarks or

registered trademarks of Stratasys Ltd. and/or its affiliates.

Note Regarding Forward-Looking

Statement

The statements in this press release regarding Stratasys are

“forward-looking statements” within the meaning of the Private

Securities Litigation Reform Act of 1995, Section 27A of the

Securities Act of 1933, and Section 21E of the Securities Exchange

Act of 1934. Forward-looking statements are subject to significant

risks and uncertainties, and actual results could differ materially

from those projected. There can be no assurance that Stratasys will

be able to complete the transaction on the anticipated terms, or at

all. Important factors that could cause actual results and

developments to differ materially from those anticipated in these

forward-looking statements include, among other things, risks and

uncertainties related to market conditions, satisfaction of

customary closing conditions related to the transaction and the

risk factors and other matters referred to under “Risk Factors”,

and generally in Stratasys’ Annual Report on Form 20-F for the year

ended December 31, 2023 filed with the U.S. Securities and Exchange

Commission, or SEC, on March 11th, 2024, and in other reports that

Stratasys furnishes to or files with the SEC from time to time.

Readers are urged to carefully review and consider the various

disclosures made in Stratasys’ SEC reports, which are designed to

advise interested parties of the risks and other factors that may

affect its business, financial condition, results of operations and

prospects. The forward-looking statements in this release speak

only as of this date, and Stratasys disclaims any intent or

obligation to revise or update publicly any forward-looking

statement except as required by law.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20240711185837/en/

Media and Investor contacts:

Stratasys Corporate, North America, EMEA and

APAC Chris Reese chris.reese@stratasys.com +1 651 357 0877

Stratasys Corporate, Israel, EMEA and APAC Erik Snider

Erik.Snider@stratasys.com +972 74 745 6053

Investor Relations Yonah Lloyd Yonah.Lloyd@stratasys.com

+972 74 745 4919

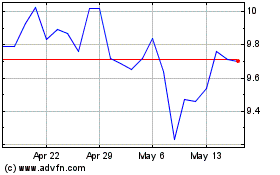

Stratasys (NASDAQ:SSYS)

Historical Stock Chart

From Dec 2024 to Jan 2025

Stratasys (NASDAQ:SSYS)

Historical Stock Chart

From Jan 2024 to Jan 2025