ACM Research Announces Major Performance Breakthrough for Ultra C Tahoe Cleaning Tool for Front-End Semiconductor Manufacturing

07 November 2024 - 8:50PM

ACM Research, Inc. (“ACM”) (NASDAQ: ACMR), a leading supplier of

wafer processing solutions for semiconductor and advanced

wafer-level packaging applications, today announced a major

performance breakthrough for its flagship Ultra C Tahoe Cleaning

tool. The resulting enhancements are designed to meet demanding

technical requirements of advanced nodes for foundry, logic and

memory applications.

The Ultra C Tahoe now achieves the performance

of standalone single-wafer cleaning tools on low-to-medium

temperature sulfuric peroxide mix (SPM) processes. Tahoe’s patented

hybrid architecture is among the first in the industry to combine

batch wafer processing and single wafer cleaning chambers into the

same SPM tool. The hybrid architecture delivers enhanced cleaning

performance, high throughput, and process flexibility, with up to

75% reduction in chemical consumption. ACM estimates cost savings

of up to $500,000 per year from sulfuric acid alone, with

additional environmental and cost benefits from reduced sulfuric

acid treatment and disposal.

“With the rise of AI to the forefront of

consumers’ minds, we expect increased public attention on the

environmental impact of semiconductor chip manufacturing. We

believe ACM’s Ultra C Tahoe is well-positioned to help customers

increase production of advanced AI chips, but with a reduced

footprint on the environment,” said Dr. David Wang, ACM’s President

and Chief Executive Officer.

“We believe the Ultra C Tahoe is another example

of excellence from ACM’s innovative and world-class R&D team,”

Dr. Wang added. “We believe the Tahoe platform is well-positioned

to capture market share within the SPM market, particularly in

middle and low-temperature applications, which believe represents

an estimated 20% of the total clean market.”

The upgraded Ultra C Tahoe is now in production

at several high-volume customer facilities in mainland China.

Additional logic and memory customers are evaluating the tool, and

we expect to deliver additional production units through the end of

2024.

New Features and Benefits of the

Upgraded Ultra C Tahoe Tool:

- Enhanced Particle

Removal: The Tahoe platform’s advanced cleaning

capabilities have achieved average particle counts of less than 6

particles at 26nm, meeting the stringent requirements for advanced

node manufacturing. The tool is also capable of removing 1x nm

particles for the most advanced logic and memory applications, with

the addition of a smaller particle filtering system.

- Higher Throughput:

The upgraded 25-slot bench module (previously 13 slots) and nine

single-wafer chambers (upgraded from eight) now deliver throughput

exceeding 200 wafers per hour, comparable to the capacity of a

12-chamber SPM system.

- Environmental and Cost

Benefits: With a reduction of up to 75% in sulfuric acid

consumption, the Ultra C Tahoe aligns with environmental

regulations and sustainability goals, reducing costs for

high-volume manufacturers.

- Expanded Process

Capabilities: Qualified for more than 30 production

layers, including key loops such as lightly-doped drain (LDD) and

source/drain (SD), with additional layers and applications

currently in development.

- Advanced Flexibility in

Single-Wafer Cleaning: Optional configurations include new

jet spray technology, ACM’s patented SAPS/TEBO technologies, and

HOT IPA drying technology, increasing the tool’s versatility across

multiple process applications.

Visit ACM at SEMICON Europa

To learn more about the upgraded Ultra C Tahoe

platform, please visit us at SEMICON Europa, booth C2265, from

November 12-15, 2024, in Munich, Germany, or explore our

website.

Forward-Looking Statements

Certain statements contained in this press release are not

historical facts and may be forward-looking statements within the

meaning of the Private Securities Litigation Reform Act of 1995.

Words such as “plans,” “expects,” “believes,” “anticipates,”

“designed,” and similar words are intended to identify

forward-looking statements. Forward-looking statements are based on

ACM management’s current expectations and beliefs, and involve a

number of risks and uncertainties that are difficult to predict and

that could cause actual results to differ materially from those

stated or implied by the forward-looking statements. A description

of certain of these risks, uncertainties and other matters can be

found in filings ACM makes with the U.S. Securities and Exchange

Commission, all of which are available at www.sec.gov. Because

forward-looking statements involve risks and uncertainties, actual

results and events may differ materially from results and events

currently expected by ACM. Readers are cautioned not to place undue

reliance on these forward-looking statements, which speak only as

of the date hereof. ACM undertakes no obligation to publicly update

these forward-looking statements to reflect events or circumstances

that occur after the date hereof or to reflect any change in its

expectations with regard to these forward-looking statements or the

occurrence of unanticipated events.

About ACM Research, Inc.ACM develops,

manufactures and sells semiconductor process equipment for

single-wafer or batch wet cleaning, electroplating, stress-free

polishing, vertical furnace processes, Track and PECVD, which are

critical to advanced semiconductor device manufacturing and

wafer-level packaging. ACM is committed to delivering

customized, high-performance, cost-effective process solutions that

semiconductor manufacturers can use in numerous manufacturing steps

to improve productivity and product yield. For more information,

visit www.acmr.com.

© ACM Research, Inc. ULTRA C, SAPS, TEBO and the ACM Research

logo are trademarks of ACM Research, Inc. For convenience, these

trademarks appear in this press release without ™ symbols, but that

practice does not mean ACM will not assert, to the fullest extent

under applicable law, its rights to such trademarks. All other

trademarks are the property of their respective owners.

| Media

Contact: |

Company

Contacts: |

| Alyssa Lundeen |

USA |

| Kiterocket |

Robert Metter |

| +1 218.398.0776 |

+1 503.367.9753 |

| alundeen@kiterocket.com |

|

| |

China |

| |

Xi Wang |

| |

ACM Research (Shanghai),

Inc. |

| |

+86 21 50808868 |

| |

|

| |

Korea |

| |

David Kim |

| |

ACM Research (Korea),

Inc. |

| |

+82 1041415171 |

| |

|

| |

Taiwan |

| |

David Chang |

| |

+886 921999884 |

| |

|

| |

Singapore |

| |

Adrian Ong |

| |

+65 8813-1107 |

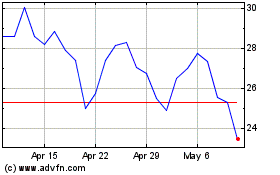

ACM Research (NASDAQ:ACMR)

Historical Stock Chart

From Oct 2024 to Nov 2024

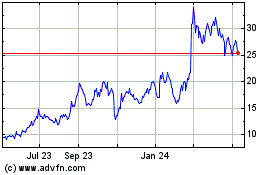

ACM Research (NASDAQ:ACMR)

Historical Stock Chart

From Nov 2023 to Nov 2024