- Europe's first battery recycling plant using integrated

mechanical-hydrometallurgical process opens in Kuppenheim in

southern Germany

- Milestone on the road to enhancing raw materials sustainability

thanks to an expected recovery rate of more than 96 percent and net

CO2 -neutral1 operation

- Plant to generate enough recycled materials to produce more

than 50,000 new battery modules per year

- Double-digit million-euro investment underpins holistic

Mercedes-Benz approach to battery circularity and value creation in

Germany

- Cooperation with technology partner Primobius and renowned

research institutes

Mercedes-Benz today opened Europe's first battery recycling

plant with an integrated mechanical-hydrometallurgical process

making it the first car manufacturer worldwide1 to close the

battery recycling loop with its own in-house facility. The

recycling plant in Kuppenheim, southern Germany, creates a genuine

circular economy. This underpins the pioneering spirit and

innovative strength of Mercedes-Benz as it strives to significantly

reduce the consumption of valuable primary resources. Unlike

existing established processes, the expected recovery rate of the

mechanical-hydrometallurgical recycling plant is more than 96

percent. Valuable and scarce raw materials such as lithium, nickel

and cobalt can be recovered – in a way which is suitable for use in

new batteries for future all-electric Mercedes-Benz vehicles. The

company has invested tens of millions of euros in the construction

of the new battery recycling plant and thus in the value creation

in Germany. Federal Chancellor Olaf Scholz and Baden-Württemberg's

Environment Minister Thekla Walker visited the plant for the

opening ceremony in Kuppenheim, Baden.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20241021402777/en/

Mercedes-Benz opens own recycling factory

to close the battery loop. Europe's first battery recycling plant

using integrated mechanical-hydrometallurgical process opens in

Kuppenheim in southern Germany. (Photo: Business Wire)

“Mercedes-Benz has set itself the goal of

building the most desirable cars in a sustainable way. As a pioneer

in automotive engineering, Europe's first integrated

mechanical-hydrometallurgical battery recycling factory marks a key

milestone towards enhancing raw-materials sustainability. Together

with our partners from industry and science, we are sending a

strong signal of innovative strength for sustainable electric

mobility and value creation in Germany and Europe.” Ola Källenius,

Chairman of the Board of Management of Mercedes-Benz Group AG

“The future of the automobile is electric, and

batteries are an essential component of this. To produce batteries

in a resource-conserving and sustainable way, recycling is also

key. The circular economy is a growth engine and, at the same time,

an essential building block for achieving our climate targets! I

congratulate Mercedes-Benz for its courage and foresight shown by

this investment in Kuppenheim. Germany remains a cutting-edge

market for new and innovative technologies.” Olaf Scholz, Federal

Chancellor of the Federal Republic of Germany

Mercedes-Benz’s technology partner for the battery recycling

factory is Primobius, a joint venture between German plant and

mechanical engineering company SMS group and Australian process

technology developer Neometals. The plant is receiving funding from

the German Federal Ministry for Economic Affairs and Climate Action

as part of a scientific research project with three German

universities. The project looks at the entire process chain for

recycling, including logistics and reintegration concepts. The

partners are thus making an important contribution to future

scaling of the battery recycling industry in Germany.

Integrated mechanical-hydrometallurgical recycling concept For

the first time in Europe, the Mercedes-Benz battery recycling plant

covers all steps from shredding battery modules to drying and

processing active battery materials. The mechanical process sorts

and separates plastics, copper, aluminium, and iron in a complex,

multi-stage process. The downstream hydrometallurgical process is

dedicated to the so-called black mass. These are the active

materials that make up the electrodes of the battery cells. The

valuable metals cobalt, nickel and lithium are extracted

individually in a multi-stage chemical process. These recyclates

are of battery quality and therefore suitable for use in the

production of new battery cells.

Unlike the pyrometallurgy established in Europe today, the

hydrometallurgical process is less intensive in terms of energy

consumption and material waste. Its low process temperatures of up

to 80 degrees Celsius mean it consumes less energy. In addition,

like all Mercedes-Benz production plants, the recycling plant

operates in a net carbon-neutral2 manner. It is supplied with 100

percent green electricity. The roof area of the 6800 square-metre

building is equipped with a photovoltaic system with a peak output

of more than 350 kilowatts.

The Mercedes-Benz battery recycling plant in Kuppenheim has an

annual capacity of 2,500 tonnes. The recovered materials feed into

the production of more than 50,000 battery modules for new

all-electric Mercedes-Benz models. The knowledge gained could help

scale up production volumes in the medium to long term.

Holistic approach to battery value creation Mercedes-Benz takes

a holistic approach to the circularity of battery systems and

considers three core topics: circular design, value retention and

closing the material loop. With its Design for Circularity

approach, the company takes the entire battery technology value

chain into account from the outset. At the Mercedes-Benz eCampus in

Stuttgart-Untertürkheim, which opened in 2024, circular thinking

flows into the development of new battery cells. Battery production

for electric Mercedes-Benz vehicles is net carbon-neutral3 in

battery factories on three continents. Local battery production is

a key factor for the success of the Mercedes-Benz sustainable

business strategy.

In line with circular thinking and to conserve resources, the

company offers reconditioned batteries as spare parts for all its

electric vehicles. In addition, its Mercedes-Benz Energy subsidiary

has established a successful business model with large-scale

stationary storage applications. Batteries that are no longer

suitable for vehicle use can enjoy a second life as part of an

energy storage system.

For Mercedes-Benz, sustainability means creating long-term value

for as many people as possible which is why it pursues a

sustainable business strategy. This means sustainability is a

fundamental component of a holistic corporate mindset that embraces

wider ecological, social and economic aspects.

Statements from the opening of the Mercedes-Benz battery

recycling plant in Kuppenheim

“We are systematically deepening our expertise

in the battery value chain. Following the opening of the

Mercedes-Benz eCampus for development of new battery cell

chemistries in Stuttgart-Untertürkheim, we are now sustainably

closing the raw materials loop in Kuppenheim. The innovative

technology enables us to recover valuable raw materials from the

battery with the highest possible degree of purity. This turns

today's batteries into tomorrow's sustainable mine for raw

materials. The new battery recycling plant strengthens the role of

the Mercedes-Benz production network with vehicle and drivetrain

plants in Europe.” J�rg Burzer, Member of the Board of Management

of Mercedes-Benz Group AG, responsible for Production, Quality

& Supply Chain Management

“Battery recycling is of great importance to

Baden-Württemberg as a state with such a strong automotive sector.

Closing the loop on the value chain reduces dependencies, increases

resilience in times of crisis and can smooth peaks and troughs in

the availability of raw materials. Mercedes-Benz is a pioneer in

this respect: With the integrated battery recycling plant,

Mercedes-Benz has developed a sustainable approach for dealing with

limited resources and is therefore making a valuable contribution

to a truly circular economy. We are proud that in this federal

state of innovators, we are also at the forefront in this field.”

Thekla Walker MdL, Minister for the Environment, Climate and Energy

Baden-Württemberg

Further information about Mercedes-Benz is available at

www.mercedes-benz.com. Press information and digital services for

journalists and multipliers can be found on our Mercedes-Benz Media

online platform at http://media.mercedes-benz.com. Learn more about

current topics and events related to Mercedes-Benz Cars & Vans

on our LinkedIn channel under Mercedes-Benz AG | LinkedIn.

Mercedes‑Benz AG at a glance Mercedes‑Benz AG is part of the

Mercedes‑Benz Group AG with a total of around 166,000 employees

worldwide and is responsible for the global business of

Mercedes‑Benz Cars and Mercedes‑Benz Vans. Ola Källenius is

Chairman of the Board of Management of Mercedes‑Benz AG. The

company focuses on the development, production and sales of

passenger cars, vans and vehicle-related services. Furthermore, the

company aspires to be the leader in the fields of electric mobility

and vehicle software. The product portfolio comprises the

Mercedes‑Benz brand with Mercedes‑AMG, Mercedes‑Maybach and G‑Class

with their all-electric models as well as products of the smart

brand. Mercedes‑Benz AG is one of the world's largest manufacturers

of luxury passenger cars. In 2023 it sold around two million

passenger cars and 447,800 vans. In its two business segments,

Mercedes‑Benz AG is continually expanding its worldwide production

network with more than 30 production sites on four continents,

while gearing itself to meet the requirements of electric mobility.

At the same time, the company is constructing and extending its

global battery production network on three continents. As

sustainability is the guiding principle of the Mercedes‑Benz

strategy and for the company itself, this means creating lasting

value for all stakeholders: for customers, employees, investors,

business partners and society as a whole. The basis for this is the

sustainable business strategy of the Mercedes‑Benz Group. The

company thus takes responsibility for the economic, ecological and

social effects of its business activities and looks at the entire

value chain.

1 Net carbon-neutral means that carbon emissions that are not

avoided or reduced at Mercedes-Benz are compensated for by

certified compensation offsetting projects. 2 According to current

knowledge 3 Net carbon-neutral means that carbon emissions that are

not avoided or reduced at Mercedes-Benz are compensated for by

certified compensation offsetting projects.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20241021402777/en/

Madeleine Herdlitschka, phone: +49 (0) 151 58 628 285,

madeleine.herdlitschka@mercedes-benz.com Birgit Zaiser, phone: +49

(0) 160 86 14 753, birgit.zaiser@mercedes-benz.com Edward Taylor,

phone: +49 (0) 176 30 941 776, edward.taylor@mercedes-benz.com

Andrea Berg, phone +1 917 667 2391,

andrea.a.berg@mercedes-benz.com

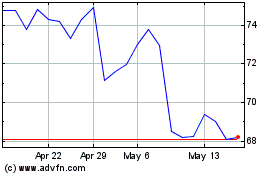

MercedesBenz (TG:MBG)

Historical Stock Chart

From Feb 2025 to Mar 2025

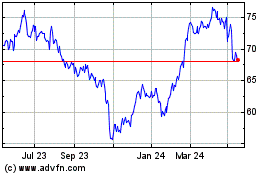

MercedesBenz (TG:MBG)

Historical Stock Chart

From Mar 2024 to Mar 2025